Humbug

|

| posted on 5/11/06 at 11:58 AM |

|

|

Flat bar for cycle wing stays

Left home yesterday morning at 6.15 to go on a track day 100 miles away, five minutes down the road my f**king cycle wing stay broke again. I decided

just to unbolt it and drive there and back with an open wheel, but I still need to get it fixed/replaced.

In this thread - http://www.locostbuilders.co.uk/viewthread.php?tid=54339 - I put up a drawing of something to try, but I just went down to Homebase

and they don't have steel bar, only "iron flat". Just wondering if that would still do the trick, or it would be too fragile either

to bend without weakening it severely, or suffer from vibrations in use? It seems to be intended to make decorative fencing from.

If not that, anyone know of sources of appropriate flat steel bar (looking for about 6mm thick by 20-25mm wide) near Sevenoaks?

EDIT: also, would I need mild steel, bright steel or black steel (terms I got from a webdite)?

Cheers

[Edited on 5/11/06 by Humbug]

|

|

|

|

|

stevec

|

| posted on 5/11/06 at 12:04 PM |

|

|

Is there one of these near you?

http://www.metalsupermarkets.co.uk/

Steve.

|

|

|

Humbug

|

| posted on 5/11/06 at 12:10 PM |

|

|

quote:

Originally posted by stevec

Is there one of these near you?

http://www.metalsupermarkets.co.uk/

Steve.

No, there isn't, but thanks for the suggestion

|

|

|

John Bonnett

|

| posted on 5/11/06 at 01:35 PM |

|

|

Hi, regarding steel supplies you should be able to find a steel stockholder near you where you will be able to buy a length of 20 x 6mm mild steel

flat. You will be amazed how cheap it is compared with the prices you may pay at the likes of B & Q. A length will be around 6 metres so you will

have plenty to play with.

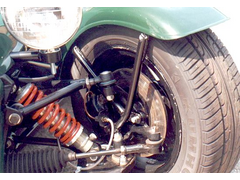

The picture shows a Dax wingstay fitted to our Special. This is a mixture of thickwall 20mm tube and 20mm x 6 flat. These stays have been on for 10

years and never given trouble.

John.jpg)

|

|

|

John Bonnett

|

| posted on 5/11/06 at 02:03 PM |

|

|

Quote

Love the trials car.

Yes, I can't wait to finish the Phoenix and get back to working with aluminium again. The trials car has been on the go for far too long and if

it's not finished soon it will be a toss up as to whether I'm finished before it is!!!

John

|

|

|

Bob C

|

| posted on 5/11/06 at 02:23 PM |

|

|

I flattened the stay tube to make the flat bit (it helps having a blacksmith in the family) No problems yet after 200m. ;^)

unfortunately that's meters not miles. . . .

Bob

|

|

|

Surrey Dave

|

| posted on 5/11/06 at 02:24 PM |

|

|

Your local blacksmith's will sell you some metal , I go to Tandridge forge near Oxted

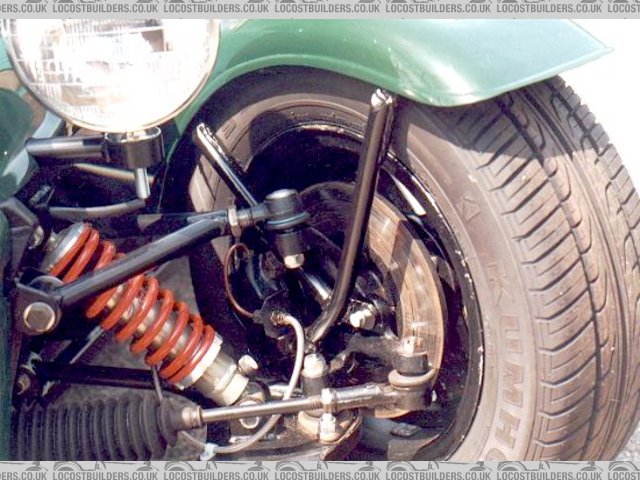

Here's my wing stays , 6 years on still not broken , ( probably will now though!!)

Rescued attachment wingstays LCB.jpg

|

|

|

Humbug

|

| posted on 8/11/06 at 08:23 AM |

|

|

so (anyone)... do I need mild steel, bright steel or black steel?

or will the iron from Homebase do?

Fozzie: what did you use to fabricate your wing stays?

Thanks

|

|

|

James

|

| posted on 8/11/06 at 02:14 PM |

|

|

Not sure on the mild, bright, black question.. sorry.

As for the stays... you sure you need a design that includes a weld?

Have a look at the way MNR do theirs (Ned has a set, pics in his archive?). it is just bent tube with no weld.

As it's the weld that breaks (the heat treating causes a weak spot) this design strikes me as ideal. And what I will do next time my stay

breaks!

Cheers,

James

------------------------------------------------------------------------------------------------------------

"The fight is won or lost far away from witnesses, behind the lines, in the gym and out there on the road, long before I dance under those lights."

- Muhammad Ali

|

|

|

Humbug

|

| posted on 10/11/06 at 10:31 PM |

|

|

On advice from Fozzie I went to a steel stockholder today and got some bright steel - the nearest they had to what I wanted (6mm x 25mm) was

1/4" x 1 1/8" (about 6mm x 29mm).

I am not planning to do any welds because of the old "ain't got a welder and can't weld anyhow" problem". I am planning

to use the original triangular plate to locate the flat bars in the right position, and bend them round at the top over the wheel - may end up having

to do two partial angles rather than trying to do a curved 90 degree bend. First job is to clean off all the grease and sh1te

quote:

Originally posted by James

Not sure on the mild, bright, black question.. sorry.

As for the stays... you sure you need a design that includes a weld?

Have a look at the way MNR do theirs (Ned has a set, pics in his archive?). it is just bent tube with no weld.

As it's the weld that breaks (the heat treating causes a weak spot) this design strikes me as ideal. And what I will do next time my stay

breaks!

Cheers,

James

[Edited on 10.11.2006 by Humbug]

|

|

|

lexi

|

| posted on 11/11/06 at 10:34 PM |

|

|

Mark Allansons are as good as I`ve seen done. A thread came up about a month ago ................copy them? Na too lazy to change mine

Alex

|

|

|