Avoneer

|

| posted on 2/5/06 at 08:04 PM |

|

|

Ali Back Panel And Cover Thoughts...

Anyone any good tips or ideas for:

1) Bending the top back corners of the rear ali panel.

2) Making a nice lid/cover that helps to cover up the corners mentioned above that fits well.

Cheers,

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

|

|

Deckman001

|

| posted on 2/5/06 at 08:06 PM |

|

|

I'm after the same sort of info as well,, as for number two though, I'm thinking of a vinyl cover with poppers onto the ally panel ? make

sense ??

Jason

|

|

|

Surrey Dave

|

| posted on 2/5/06 at 08:16 PM |

|

|

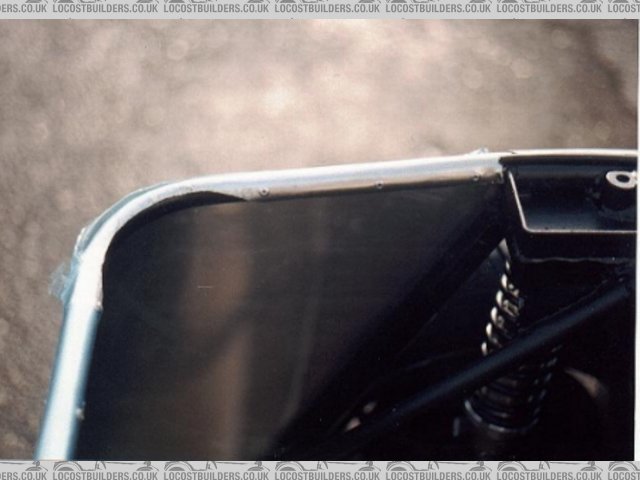

Keep ally in good contact with the tubes or it will try to crease, you can also cut the ally so that you only have to wrap it 90 degrees on the inside

of the corners.

Rescued attachment rearcorneralloy sml.jpg

|

|

|

Deckman001

|

| posted on 2/5/06 at 08:19 PM |

|

|

But doesn't that take a lot of skill and cups of tea ???

Jason

|

|

|

Surrey Dave

|

| posted on 2/5/06 at 08:20 PM |

|

|

Boot Cover

Rescued attachment bootbox1 sml.jpg

|

|

|

Deckman001

|

| posted on 2/5/06 at 08:21 PM |

|

|

You can guess where i am hoping to borrow my plan from can't you

Jason

|

|

|

Surrey Dave

|

| posted on 2/5/06 at 08:25 PM |

|

|

No....

This was the only time I have done this kind of thing, I cut a big template out of cardboard then cut the ally, fixed it on the back and formed round,

complete ignorance gives good confidence sometimes!!!

But it is virtually a sheet of ally gone if you blunder badly.....

One of my corners came out better than the other , that was where I learnt that the metal MUST be firm against the tube.

[Edited on 2/5/06 by Surrey Dave]

|

|

|

Avoneer

|

| posted on 2/5/06 at 08:26 PM |

|

|

Yep, thats almost like how I did mine.

Just don't want to use a tonneau as I have large back braces and the filler cap is right near the top of the ali panel.

Any other thoughts?

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Trev D

|

| posted on 2/5/06 at 08:31 PM |

|

|

Dave has given good advice; cut it short it will make life so much easier for you.

|

|

|

Surrey Dave

|

| posted on 2/5/06 at 08:36 PM |

|

|

Thanks Trev D..

Thanks Trev D , I'll take that as a compliment from you , your car is a work art, amazing metalwork skills , wow the curves on those front

arches (phew!)

|

|

|

Trev D

|

| posted on 2/5/06 at 08:43 PM |

|

|

Thanks Dave

|

|

|

Surrey Dave

|

| posted on 2/5/06 at 08:44 PM |

|

|

Fozzie's boot cover

Rescued attachment Fozzie OS Rear sml.jpg

|

|

|

Avoneer

|

| posted on 2/5/06 at 09:06 PM |

|

|

Got Trev's number for advice - just not got round to using it yet

Where's Fozzie when you need her - that's exactly how I want mine.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Surrey Dave

|

| posted on 2/5/06 at 09:43 PM |

|

|

Barbados I fink!!!

I've got a feeling that a piece of strip was welded around the inside of the top tube, sort of halfway down the inside (90deg from the top),

then the panel was fitted and shaped over to rest on the strip giving a recess for the top ally to sit in.

If I'm wrong , I tried!!!

[Edited on 2/5/06 by Surrey Dave]

|

|

|

indykid

|

| posted on 2/5/06 at 09:58 PM |

|

|

quote:

Originally posted by Avoneer

- that's exactly how I want mine.

Pat...

no it's not, that looks bloody hard.

i told you we needed to cut more out of the corners though!

tom

|

|

|