02GF74

|

| posted on 13/1/06 at 12:08 PM |

|

|

after the 'how to fibreglass' post

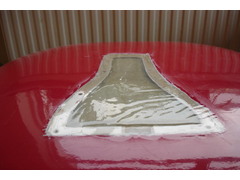

Here is my first attempt using fibre glass; quite pleased with the result.

The nose cone had this poxy air vent that I could not see any great benefit from having plus someone said it was not SVA compliant so off it came and

the hole filled in.

Using poly sheet resulted in a reasonably flat finish, albeit with some nice ripples!

ripples

As seen from top

air vent blocked top view

and finally from below (not that exciting).

from below

A bit of body filler, smooth it down, primer and ready to go!

What I did learn is to keep old food tins as they make ideal mixing containers, in particular sardine tins as they as nice and low. Old tablespoon

and teaspoons useful to measure out and mix. Messy work innit!

|

|

|

|

|

emsfactory

|

| posted on 13/1/06 at 12:13 PM |

|

|

Really messy, but good fun.

You get less messy the more you do.

I have a big box full of old baked bean tins etc, not a fan of sardines though the tins would be good

|

|

|

Hugh Paterson

|

| posted on 13/1/06 at 05:11 PM |

|

|

Nice patch, let me know when your interested in 40 wheel arches for a bus company were working on just now, or would you like to start on somthing

small like the coin trays? ( pain in the arse)

|

|

|

Triton

|

| posted on 13/1/06 at 10:05 PM |

|

|

If you are not making a mess you are not working hard enough....

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

Chippy

|

| posted on 13/1/06 at 10:41 PM |

|

|

I find that the tubs marj comes in work well, they don't melt and you can easily get the hardened residue out after. Nothing like a good

day's GRP'ing, your cloths stand to attention, (without you in them). And the smell, nearly as good as one of those funny fags.

|

|

|

Triton

|

| posted on 13/1/06 at 10:54 PM |

|

|

Styrene induced headaches are not too clever though so better to wear a mask that kills the vapour and dust....good price from CFS at 12 nuggets..well

worth it.

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

Jasper

|

| posted on 14/1/06 at 04:59 PM |

|

|

Just did my first bit of 'grown up' glassing last night, and so far it looks good - a nice pair of fat arches for the back of my car. What

made a huge difference was getting good quality glass matting from a local specialist supplier, it holds together SO much better than the thin crap

from Halfrauds etc. He was cheap too, a big sheet of glass, 4 x small sheets of carbon fibre style (square woven) glass, a medium tin of resin and

hardener, all for a tenner.

Got a bit worried when it wouldn't go off, then realise the garage was a bit cold and stuck a blower heater and, and hey-presto.

Next step is filler which requires patience for sanding down, something I'm not very good at!!

|

|

|

Peteff

|

| posted on 14/1/06 at 05:05 PM |

|

|

Next step is filler which requires patience for sanding down,

Not if you get some 40 grit production paper  . Get ripping . Get ripping

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

stevebubs

|

| posted on 14/1/06 at 05:11 PM |

|

|

I found a Black & Decker belt sander with 120 grit MORE than capable to get the intial shape....then it was down to good old wet&dry -

starting with 120 to get the shape and slowly moving up the grades..

|

|

|