DIY Si

|

| posted on 11/2/07 at 12:18 PM |

|

|

Bloody hell that looks a bit complex! Good news on the progress front though, I was beginning to wonder if you'd had some major drawback or

problem! How are you planning on doing the first layer of the moulds? Or are you filling all the gaps with something like polystyrene and then going

over that?

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

|

|

Fred W B

|

| posted on 11/2/07 at 12:23 PM |

|

|

Hi DIY

The hold up was this

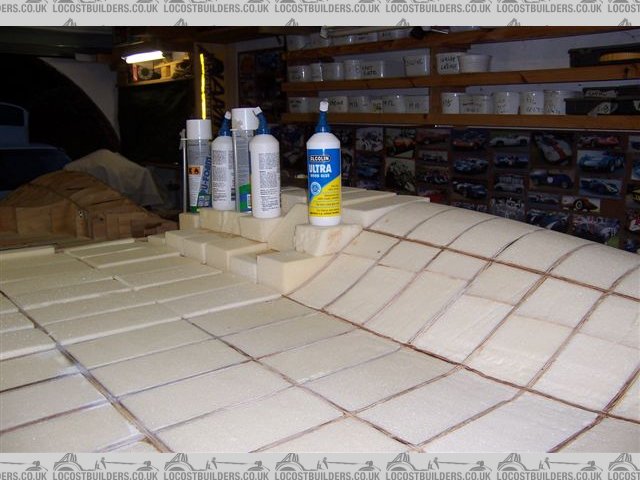

WRT skinning the plug, I have had 350 polyurethane foam blocks cut, to glue into the "egg box" spaces to form the surface. These will be

finished to shape and then the whole thing skinned with GRP and filler.

Cheers

Fred W B

[Edited on 11/2/07 by Fred W B]

|

|

|

DIY Si

|

| posted on 11/2/07 at 12:58 PM |

|

|

Ah, I'd forgotten about that. Fair enough, I would gladly take time out to make such a nice garage/build space. Any guesses as to when the

buck'll be ready? I imagine that'll be a fair sight all on it's own.

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

RazMan

|

| posted on 11/2/07 at 02:30 PM |

|

|

I'm following your project with growing interest Fred.

When covering the 'egg box' with GRP are you going to anchor it to the surface with load spreader plates or similar? I was just thinking

that it might need to be bonded in some way to avoid separation when it comes to removing the buck from the mould. Or is it going to be a sacrificial

buck?

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

sgraber

|

| posted on 11/2/07 at 02:46 PM |

|

|

Great progress Fred, and forgive me as I take the podium to say that you are doing the right thing by making sure you have a good base to start from.

If I can give any advice to people seeing Fred's complex structure who are considering their own buck/plug/mold construct - Do not skimp on the

understructure. I did, and paid for it over the years of struggle to prevent shifting and cracking.

Now, we could have a whole conversation about CNC milling the plug vs hand shaping.... But this is not the time or the place. Just LOOK at that

amazing wood work! Lovely!

Steve Graber

http://www.grabercars.com/

"Quickness through lightness"

|

|

|

Fred W B

|

| posted on 12/2/07 at 02:56 PM |

|

|

Hi Guys

Raz, I am hoping that the "skin" of GRP/filler will stay on the plug when I pull the moulds. I hadn't planned on doing anything more

then just relying on the resin to stick the skin to the wood and foam base

Cheers

Fred W B

[Edited on 12/2/07 by Fred W B]

|

|

|

thomas4age

|

| posted on 12/2/07 at 11:22 PM |

|

|

HolySh*T that is indeed very nice,

makes me kindoff ashamed that I'm being a wuss, saving up for the GD t70 chassis and body.......

if I only had the time and skills to pull that off.

grtz Thomas

If Lucas made guns, Wars wouldn't start either.

|

|

|

DIY Si

|

| posted on 12/2/07 at 11:24 PM |

|

|

Just do what I might do, and buy a shell off him!

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

Fred W B

|

| posted on 18/2/07 at 04:10 PM |

|

|

Made some progress on the front section this weekend.

WRT diy si's comment, would you believe that since I've been posting details of my project on here and on GT40s.com, I've had 5

different guys contact me wanting bodyshells. I tell them I'm not quite ready yet........

Cheers

Fred W B

buck16feb

|

|

|

RazMan

|

| posted on 18/2/07 at 06:13 PM |

|

|

Hey Fred, it's starting to look like a car now!

Cheers,

Raz

When thinking outside the box doesn't work any more, it's time to build a new box

|

|

|

Gaz 1977

|

| posted on 19/2/07 at 09:17 AM |

|

|

wow

looking good, christ you have put some work into that

|

|

|

gttman

|

| posted on 19/2/07 at 03:05 PM |

|

|

quote:

Originally posted by Fred W B

Made some progress on the front section this weekend.

WRT diy si's comment, would you believe that since I've been posting details of my project on here and on GT40s.com, I've had 5

different guys contact me wanting bodyshells. I tell them I'm not quite ready yet........

Cheers

Fred W B

I can well beleive it.... I've had people pressure me to provide them a body and I hadn't even designed the rear end at the time.....

nothing stranger than folk.

keep up the good work.

Andygtt

Please redefine your limits

|

|

|

Fred W B

|

| posted on 30/4/07 at 08:22 AM |

|

|

some process photos

body22

|

|

|

Fred W B

|

| posted on 30/4/07 at 08:24 AM |

|

|

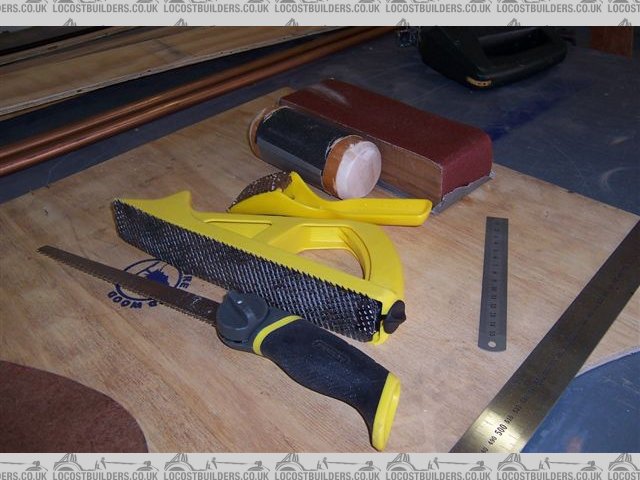

foam shaping tools

body23

|

|

|

Fred W B

|

| posted on 30/4/07 at 08:27 AM |

|

|

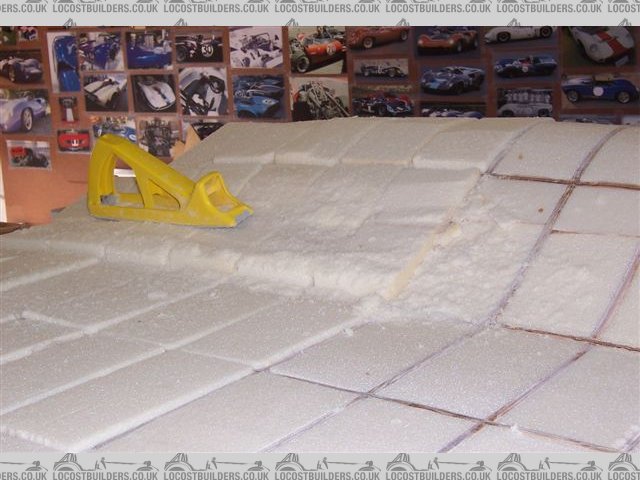

body 23.5

|

|

|

Fred W B

|

| posted on 30/4/07 at 08:28 AM |

|

|

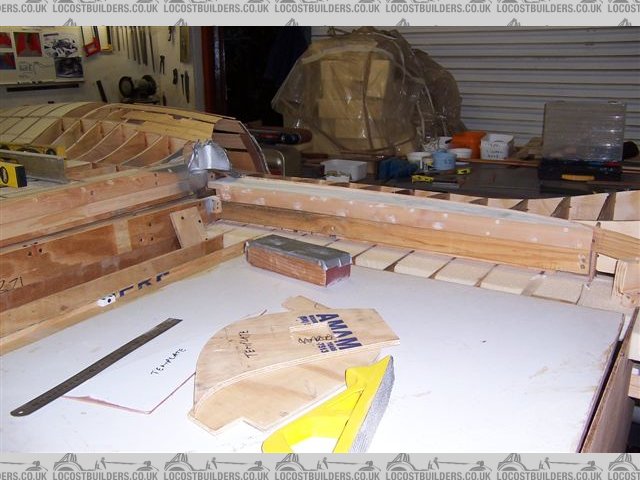

body 25

|

|

|

Doug68

|

| posted on 30/4/07 at 09:25 AM |

|

|

Awesome work Fred!

How long did it take the router guy to turn that lot out?

|

|

|

iank

|

| posted on 30/4/07 at 10:13 AM |

|

|

quote:

Originally posted by gttman

quote:

Originally posted by Fred W B

Made some progress on the front section this weekend.

WRT diy si's comment, would you believe that since I've been posting details of my project on here and on GT40s.com, I've had 5

different guys contact me wanting bodyshells. I tell them I'm not quite ready yet........

Cheers

Fred W B

I can well beleive it.... I've had people pressure me to provide them a body and I hadn't even designed the rear end at the time.....

nothing stranger than folk.

keep up the good work.

Most will melt away when the issue of getting paid to make one is raised.

Some things about folk are rather predictable unfortunately.

Looking very good (both of you) wish I had the time, space, money and talent* to make exactly what I want.

* Not necessarily in that order

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

Fred W B

|

| posted on 30/4/07 at 10:52 AM |

|

|

Thanks Doug and iank

WRT the routing, the handling time was much more of a factor that the cutting time. The job was done in between real paying jobs, and took 3 or 4

weeks to complete, I think - It was a while ago!

Things I would do different next time would include putting 0.5 mm clearance in the interlocking slots (I made them dead 8 mm wide, to fit over the 8

mm ply and had to hammer the longitudinals in) and I would add some stations at the extreme rear, but fitted perpendicular to the body surface, not

vertical. I would also make the longitudinal ribs thickness stick into the body shape from the actual longitudinal line, and not out as I have done. I

still have to finish off all these edges flush with the eventual body surface.

Best thing I did was have lots of 92 mm wide planks cut, I've used them a lot to get spacing correct at various places, particularly on the base

board. (my stations are at 100 centres, ply is 8 mm)

As for supplying others with bodies, I am under no illusions as to how many people will actually stump up money. Out here we have an expression which

comes to mind whever anyone asks me if I can make them something - "Talk is cheap, money buys the whiskey!"

I want the wheel arches to look like this car. Over the years the wheel arch lips on original 70's seem to have varied quite a bit.

wa 2

[Edited on 30/4/07 by Fred W B]

[Edited on 30/4/07 by Fred W B]

|

|

|

Fred W B

|

| posted on 30/4/07 at 10:54 AM |

|

|

body 30

|

|

|

Fred W B

|

| posted on 30/4/07 at 10:55 AM |

|

|

body 32

|

|

|

Fred W B

|

| posted on 30/4/07 at 10:57 AM |

|

|

body 36

|

|

|

Fred W B

|

| posted on 30/4/07 at 10:59 AM |

|

|

I think I have to start getting the hard skin on before I can get this any better.

body 38

|

|

|

Fred W B

|

| posted on 30/4/07 at 11:01 AM |

|

|

body 40

|

|

|

Fred W B

|

| posted on 30/4/07 at 11:04 AM |

|

|

I am now trying to get to grips with the air intake "nostrils" and complete the cockpit edges.

Cheers

Fred W B

body 42

|

|

|