GonzoRacer

|

| posted on 11/10/12 at 02:05 PM |

|

|

Good morning from the USA-

Your craftmanship and patience is just amazing. I can't wait to see more, and to see the completed car!

Well done, Sir!

JD Kemp

"And it wasn't even a full moon."

|

|

|

|

|

Fred W B

|

| posted on 11/10/12 at 05:07 PM |

|

|

Thanks for the kind comments Guys

Andy, I've pretty much given up predicting when things will be finished, but I'm hoping that I should be into making parts by the turn of

the year.

For the parts i'm planning on using ordinary Poly resin and glass matt (tissue, 1 x 300 + 2 x 600). Might add some foam between skins at some

points, not decided yet

Cheers

Fred W B

[Edited on 11/10/12 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 14/10/12 at 04:07 PM |

|

|

Have now completed the transom panel mould section. Also added bracing to it and to the side sections.

[Edited on 14/10/12 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 14/10/12 at 04:11 PM |

|

|

and released the first side section. It came off easily enough.

I have to take these off now to get the parting fences off, before I put them back on and can carry on with the final piece of the tail mould, the top

section.

Cheers

Fred W B

[Edited on 14/10/12 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 19/10/12 at 07:07 PM |

|

|

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

smart51

|

| posted on 19/10/12 at 08:47 PM |

|

|

So you're ready for the final part of the mould. It's getting exciting now.

|

|

|

Fred W B

|

| posted on 21/10/12 at 04:43 PM |

|

|

Yes, getting there.

Knocked up an elevated walkway around the tail to make it easier to work on the upper surface

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

ceebmoj

|

| posted on 14/12/12 at 11:43 AM |

|

|

hi there,

Have you made any progress?

|

|

|

HowardB

|

| posted on 14/12/12 at 12:01 PM |

|

|

I am seriously thinking that we should run trips to see Fred's work on this,... I am really looking forward to seeing the pictures.

Howard

Fisher Fury was 2000 Zetec - now a 1600 (it Lives again  and goes zoom) and goes zoom)

|

|

|

smart51

|

| posted on 14/12/12 at 12:20 PM |

|

|

Yeah, very much looking forward to the next installment. Have you done the rear deck yet Fred?

|

|

|

Fred W B

|

| posted on 15/12/12 at 04:09 PM |

|

|

Thanks for the interest guys. Over the last few weeks it has been difficult to find much garage time but I am now just about finished with the top of

the tail mould. In fact today I finished making up the wood bracing, and should get it bonded on tomorrow.

A few pictures of the braces in position but not yet bonded on. You can see that I am experimenting with putting a strip of closed cell foam between

the braces and the surface of the mould. This is to hopefully prevent "print through" from the braces on the large flat expanse of the

tail top surface

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 15/12/12 at 04:20 PM |

|

|

This was a big area, over 3 M2, and each session of two layers of mat needed about 10 kg of Resin.

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

ceebmoj

|

| posted on 15/12/12 at 04:37 PM |

|

|

Looks great as all ways. Is this the last pice of the mould? If so what is next?

|

|

|

smart51

|

| posted on 15/12/12 at 04:40 PM |

|

|

I'd never considered print through from wooden braces. I like attention to detail like this.

|

|

|

sylva_phoenix

|

| posted on 20/12/12 at 08:50 PM |

|

|

That's a fantastic project. I planned to do something similar, but Time and money won't allow it....

|

|

|

Fred W B

|

| posted on 21/12/12 at 05:02 PM |

|

|

Thanks for the comments guys

quote:

Is this the last pice of the mould?

Yes, thank the pope!

quote:

If so what is next?

Real body Parts!

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

Fred W B

|

| posted on 24/12/12 at 02:11 PM |

|

|

And now the tail mold bracing is bonded on, all the fastening bolts through the flanges are fitted and finally I can say the body molds are finished!!

Only took 1 week short of 6 years since starting to build the pattern.

Have a good Christmas and New Year All!

Cheers

Fred W B

[Edited on 24/12/12 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

rdodger

|

| posted on 24/12/12 at 02:27 PM |

|

|

Awesome work Fed!

I hope it doesn't take you another 6 years to complete a car! I can't wait that long to see it!!!!

|

|

|

TimC

|

| posted on 24/12/12 at 02:49 PM |

|

|

Merry Christmas Fred. Absolutely awesome work.

|

|

|

ceebmoj

|

| posted on 24/12/12 at 02:49 PM |

|

|

congratulations on reaching this mile stone. I look forward to seeing bits of body work.

|

|

|

GonzoRacer

|

| posted on 24/12/12 at 04:37 PM |

|

|

Your work continually amazes me. Great designs, great attention to detail, all around world-class workmanship. I'm looking forward to seeing

more.

Merry Christmas to you and yours, and good wishes for 2013.

Regards-

JD Kemp

"And it wasn't even a full moon."

|

|

|

chrsgrain

|

| posted on 27/12/12 at 06:34 PM |

|

|

Awesome, awesome, awesome.....

Bring on the body parts! Decided on a colour yet?

Chris

Spoing! - the sound of an irony meter breaking...

|

|

|

Fred W B

|

| posted on 28/12/12 at 12:04 PM |

|

|

Thanks Chris

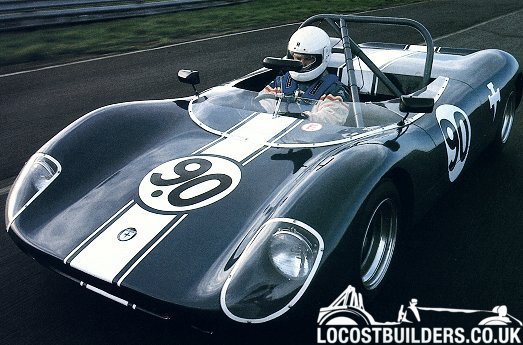

As for the colour, I will initially get the car running and debugged in the white gell coat, but eventually the plan is to paint it a deep blood red

and silver, just like the single seater below (the current favourite is Honda's "Milano Red" as seen on a Jazz or other model near

you).

Sills will be the silver below the beltline as well, running into a gulf GT40 style "moustach". Stripe will be a broad centre stripe with

two smaller stripes each side, like the second picture below, but with wider side stripes, more like the third pic, but here maybe too wide. Also here

the red is too maroon for my taste.

Maybe now you are sorry you asked, but I have been thinking about this a lot......

Cheers

Fred W B

[Edited on 28/12/12 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

ceebmoj

|

| posted on 19/3/13 at 07:13 PM |

|

|

hi, Hows the project going?

|

|

|

Fred W B

|

| posted on 20/3/13 at 08:17 PM |

|

|

Hi Ceeb, Thanks for the interest

The short answer is that I now have both doors made

and the scuttle is laid up, I just want to leave it in the mold a few more days before I pull it.

As I wanted to have returns on most of the scuttle edges making the part turned out to be a bit of a nightmare.

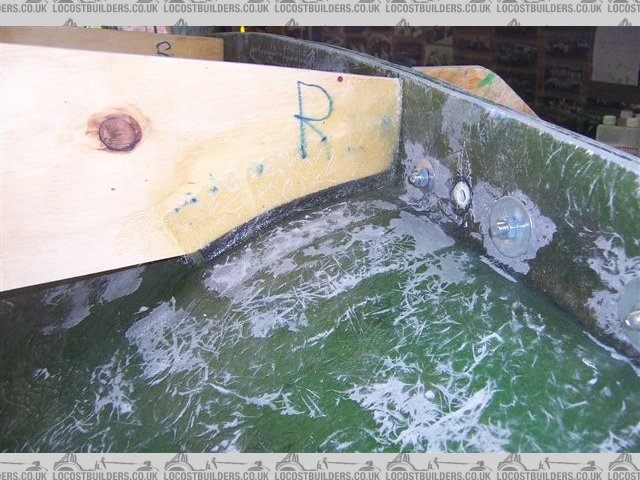

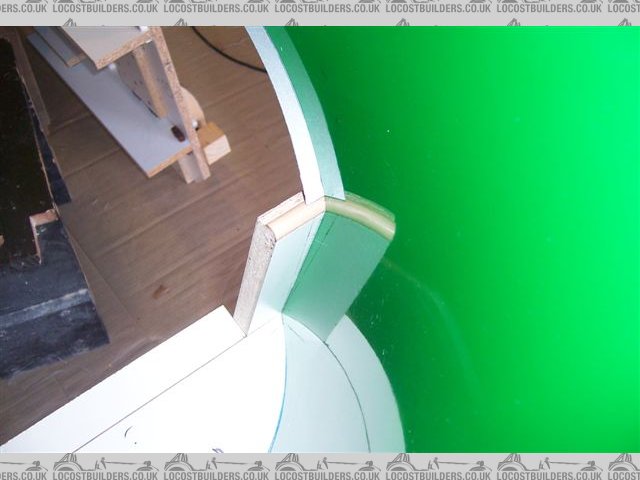

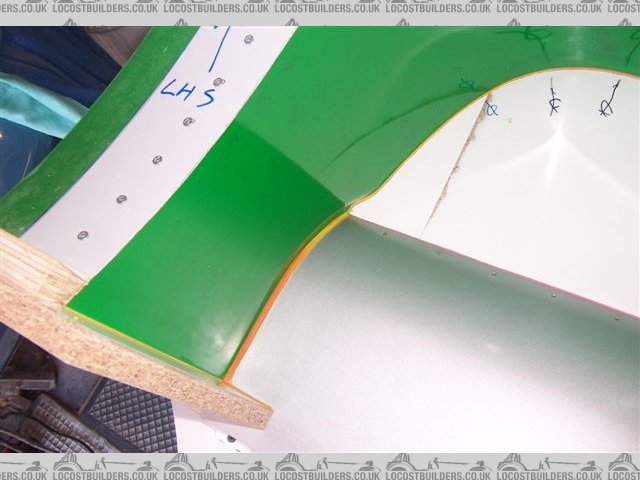

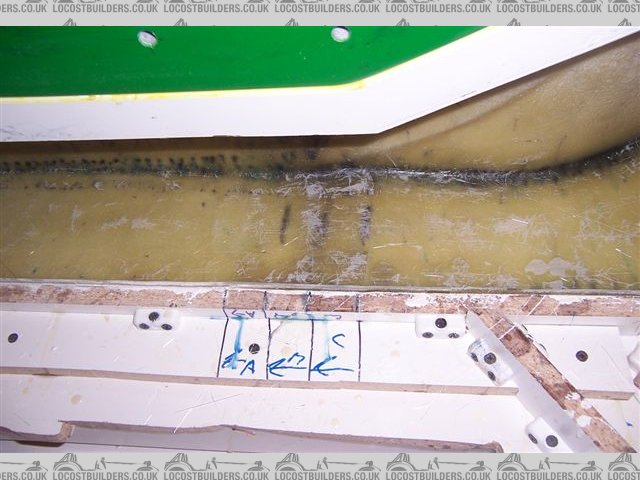

In the below two pictures the camera is held where it is not possible to get your head, so some of the detail on the return flanges had to be laid up

blind (and some upside down!).

Because of this complexity I decided to lay-up the scuttle in three sections. The left hand and right hand pieces were done first. The above and below

picture is of the side I did first, I got the flanges neater on the next one.

These were then connected by doing the centre section later.

The layers in the lay-up in the join area are tapered to try keep the thickness even across the joint. I did make a bit of a mess of the gell side of

the joint, but I think it can be saved by sanding and it's experience that will stand me in good stead on the larger parts still to be made. The

picture below is of one side of this joint.

And just tonight I've added internal flanges to support the body shape where the perimeter flange has to be omitted to permit the door to

open.

So I feel that some good progress has been made as 3 body sections are now finished. Just the small detail that the nose and tail which are still to

be done each have a larger area than all 3 parts made so far.

Cheers

Fred W B

[Edited on 20/3/13 by Fred W B]

[Edited on 20/3/13 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|