cheers for the help

[Edited on 2/3/08 by eccsmk]

im repairing a bonnet and keep getting air trapped in the edges of the bonnet scoop meaning lots and lots of sanding

any fibreglass experts online??

thank you in advance folks

What technique are you using? You should be working it in with a paintbrush, in a kinda dabbing motion (stippleing). Dont be tempted to flood it with resin, just use as much as you can get away with, whilst not leaving any dry spots.

yeah using paint brush to push the air away to the edge of the glass but it just slowly fill a pocket of air again. i'll have another bash

tomorrow night

cheers for the help

[Edited on 2/3/08 by eccsmk]

As the fibre resin is starting to cure, use a metal roller (available from fibreglass suppliers) to push the air to the edges.

or you could be using too much catty (hardener) so the resin is getting warm and the air is expanding as it's curing.

i'll have a play tomorrow night thanks folks

mixing 20ml catalist to 1kg of resin so should be ok

ill pop round and pick up a new roller tomorrow too

again thank you

If you are trying to make the GRP go round/over a sharp edge you may never be able to stop the air from getting in. GRP does not like sharp corners, needs to be nicely rounded. HTH Ray

http://www.ecfibreglasssupplies.co.uk/store/

If youare still stuck phone these guys - it is their business and they are very good. Also very competitive on price for raw materials.

hth

Mike

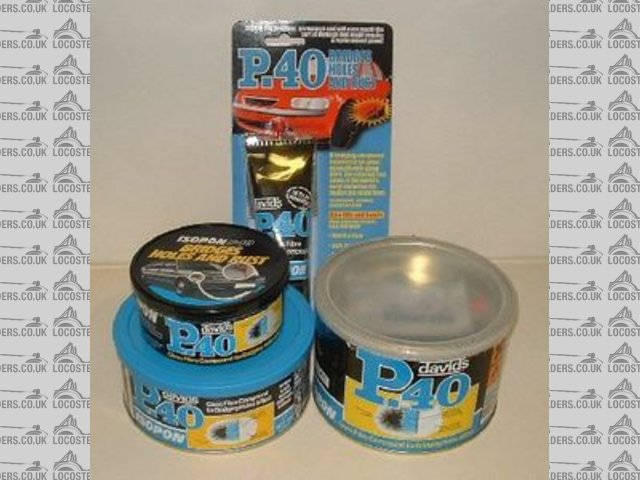

or use P40 for bit like that, great stuff and can be used in any problem areas, it's also very strong.

Rescued attachment isoponp40range.jpg

Does sound rather like you are trying to mould the glass over a shape it cannot conform to. If possible you could rig up either a vacuum or pressure

application to get over the problem - something as simple as a dustbin liner filled with sand can do wonders! Needs to be quite thin plastic and a lot

of sand.

A bit of a bodged version of the professional vac forming

thanks folks

finished it just now in my erm lunch break

i used some loose glass (chopped off ends) to smooth out the sharpe edge then added 4 layers of 2oz to strengthen up around the scoop

when i get back on stturday ill pop up some pictures

thanks again

[Edited on 3/3/08 by eccsmk]

As Whippy says, using a little chopped strand P40 in the troublesome areas can stop air pockets forming. The normal matting will not like going round sharp corners so the P40 will fill the voids nicely and keep the joint strong.

i'll see how it looks later in week should be ok now

i'll even put my camera on charge now so i dont forget later

thank you

[Edited on 3/3/08 by eccsmk]