english wheel

oadamo - 6/12/07 at 12:20 AM

hi has anybody made a locost version of an english wheel and had any luck with it. ive found some bearing at work and the outer bits got a good rad on

it. so i was thinking of trying to make one. how do you go about using one.

adam

ed_crouch - 6/12/07 at 12:40 AM

Dont know much about wheeling, but the concept you have to grasp is that sheet metal is a lot like plasticene.

It just takes a much higher force to move it. If you can provide that force by clamping it hard, you can do whatever you want with it. I guess there

is the problem of the metal becoming too thin and breaking up...

You'd need a LOT of space to make one that was of any use on something like a nosecone...

Ed.

Volvorsport - 6/12/07 at 12:45 AM

http://www.roddingroundtable.com/tech/articles/12ewheel.html

iank - 6/12/07 at 12:51 AM

907 made one - lots of information in this thread

http://www.locostbuilders.co.uk/viewthread.php?tid=21991

907 - 6/12/07 at 06:35 PM

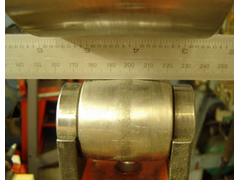

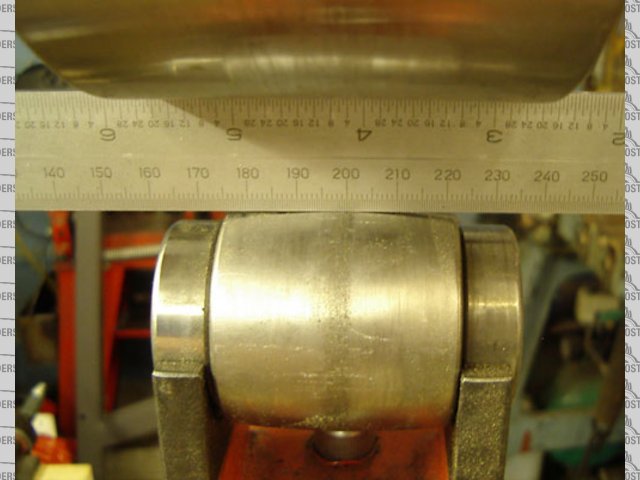

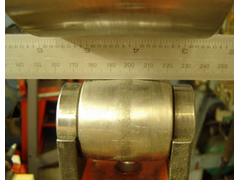

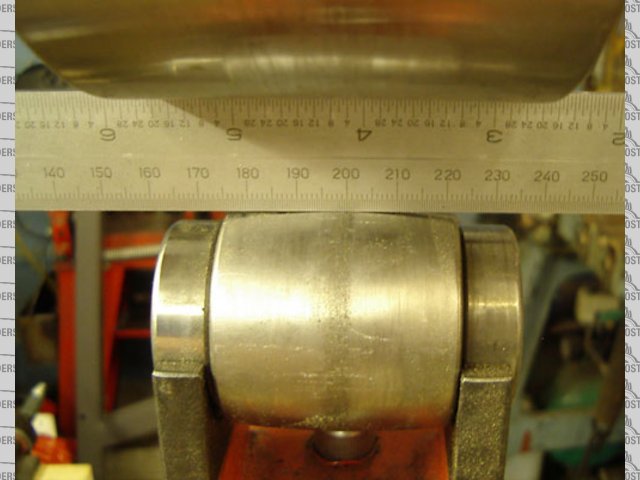

The key to a successful e wheel is the shape of the bottom wheel.

It works best if it's a radius, then a straight, then a radius again.

This is not the same as a single radius with a flat on it, if you get my drift.

Very little pressure is needed to form a shape. Ally can be pushed through the wheel with one finger.

Paul G

Rescued attachment Wheel-shape-004-s.jpg

David Jenkins - 6/12/07 at 07:03 PM

quote:

Originally posted by 907

Ally can be pushed through the wheel with one finger.

So how do you keep a grip on it, with just one finger?

Trev D - 6/12/07 at 08:33 PM

Somebody on the other end to push it back

907 - 6/12/07 at 08:41 PM

quote:

Originally posted by Trev D

Somebody on the other end to push it back

Hi ya Trev.

Wait for it... He'll be back to tell us that's TWO fingers.

Paul G

David Jenkins - 6/12/07 at 09:01 PM

Now would I do a thing like that?

Trev D - 6/12/07 at 10:11 PM

Hi Adam if you fancy having a go on a english wheel and if you are not too far from Northampton let me know and we an arrange a day and a time for you

to come over .

regards Trev

oadamo - 7/12/07 at 08:37 PM

quote:

Originally posted by Trev D

Hi Adam if you fancy having a go on a english wheel and if you are not too far from Northampton let me know and we an arrange a day and a time for you

to come over .

regards Trev

hi iam miles away but would of loved to of come over to have a go but thanks for the offer.

adam