Making aluminum scuttle

C10CoryM - 21/11/06 at 01:28 AM

Aluminium if you prefer  .

.

Anyhow, thinking about how to fabricate stuff and the scuttle is one spot where I am a bit stuck. I know what to do for the bonnet side/lip, but the

dash side Im not sure about. I do not want just a flat edge there. Even if I finish it nicely into the dash pad I dont think it will look....

right.

Ideally what I would like is a curve that comes off the top of the scuttle and bends back into the dashpad. But I think that may be too much for my

(lack of) sheet metal skills.

Any ideas on how to do this or any pics of what others have done instead?

Thanks,

Cory.

JAG - 21/11/06 at 08:59 AM

On the dash side you could always wire-roll the edge. That involves laying a small diameter wire on the edge and folding the edge back over the wire.

It's relatively easy to do and only takes a soft faced mallet (hide is best) and some patience.

It gives a nice rounded edge with no sharp bits etc... if you get it right

mad dad - 21/11/06 at 04:05 PM

sorry this is totally irrelevant to your question but my brother lives in Vancouver - what a small world.........

Chippy - 21/11/06 at 04:36 PM

Hi Cory, if you can get a length of tube, (diameter to your preference), bent to the exact inside shape of your scuttle, you could either weld the

tube (if alloy), to the scuttle, and dash panel, or dress the ally over it, (if steel), and discard the tube after. Just a thought but may give you

the effect that you desire. hth Ray

John Bonnett - 21/11/06 at 05:36 PM

Hi Cory, Normally, the aluminium is dressed over the round tube that forms the dashboard end of the scuttle.

One way of doing this is to clamp the aluminium to the vertical diameter of the tube and trim it to about 45mm from the clamping point. I have used

thin plywood which is very flexible between clamp and aluminium and will hold the aluminium against the tube even on the bends. Use as many clamps as

you can lay your hands on. You cannot have too many. Use a hardwood dolly and tap the aluminium round. Be patient and remember that metal responds to

many light blows rather than a few heavy ones. You may have to anneal the aluminium particularly on the bends as it work hardens. If necessary, the

aluminium can be rivetted underneath making the fixings totally invisible.

The dashboard can go behind the top rail a la Caterham which if I understand your question correctly is what you are trying to achieve. I did this on

our Special and it worked well.

John

Mark Allanson - 21/11/06 at 07:25 PM

Try this

Liam - 21/11/06 at 09:45 PM

I made an mdf former with steady jigsawing and a router with 1/2" bullnose bit. Then dressed the ally round it. Two things i'd do

differently if i did it again - use the correct grade of aluminium so it isn't an absolute pig to form, and get use of a shrinker so I dont have

to cut notches in the ally a-la the rear panel. Mine's being painted so it doesn't matter that i've had to use filler, but it still

woulda been nicer not to have cut the notches!

Dressing round a steel tube would have been less hassle than making the former, but i couldn't see how i'd get the nice smooth curve over

the top of the scuttle. If you dont mind a flat top this might be the way to go.

Some photos in me archive anyway.

Liam

C10CoryM - 23/11/06 at 03:37 AM

Thanks guys,

Couldn't open the PDF file for some reason. Too impatient probably  .

.

I figured beating it over a tube but thought the curves would be too much to do w/o cutting/welding or shrinking. Don't really have equip to

weld aluminum and not good enough to shrink that much. Also wasn't sure how to clamp it well enough.

The wire rolling sounds neat. Ive heard of it but never seen it done. Any links? I had a quick look and didnt see much info.

More mulling to do yet I guess.

Mad Dad, I only have a few friends, but 2 of them are from the UK so its not as odd as you would think  One from Liverpool and one from the Isle

of Wight I think.

One from Liverpool and one from the Isle

of Wight I think.

Cheers.

John Bonnett - 23/11/06 at 06:18 PM

Have a look at Ron Fournier's website. I bought his videos and armed only with that knowledge embarked on the bodywork for the trials car.

http://www.fournierenterprises.com/cart/product.php?productid=16172&cat=2&page=1

There are a few pictures in the album. He covers everything you need to know about making bucks and patterns and producing shapes just with hand

tools. It is quite amazing to see how metal can move and actually shrink into itself by just using a wooden slapper. It's not difficult and you

will be amazed at what you can achieve.

Keep us posted.

John

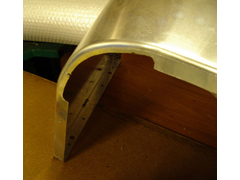

907 - 23/11/06 at 07:33 PM

Hi.

I built a 25mm box frame for my scuttle, then clad it in ally.

For the corners that need to shrink I cut down the width of the web and it knocked over with no probs.

Just work along the edge a bit at a time. Knock it over 20deg, then work along again to 40deg, then 60 etc etc.

I use a hard rubber hammer.

The best bit of advise I've had was from Trev D.

He said, "Don't be afraid of it."

HTH

Paul G

Rescued attachment scuttle-corner-s.jpg

C10CoryM - 24/11/06 at 03:39 AM

Thanks guys,

Looks good Paul, if I get those results I will be happy. What thickness/type of aluminum is that?

I guess I will give it one go, and If I screw that up I'll just go for a flat edge and finish it nicely. I work with a guy who is good with

metal so maybe I can bribe him to teach me a bit.

Still waiting on my shop. I hope to start building in January. Just trying to sort out some things that Im unsure on before going on a buying spree

. I think I will be able to move pretty fast once I get going.

. I think I will be able to move pretty fast once I get going.

Thanks again.

907 - 25/11/06 at 09:39 AM

Hi

The metal stockists in my area tend to stock the standard stuff. Anything else is a special order that you have to wait weeks for.

I think it's 1050A , H4, (H14 in USA and Canada) 99.5% pure, and referred to as half hard.

It's 1.5mm thick or 16swg (ish)

hth

Paul G

Dick Bear - 27/11/06 at 12:52 AM

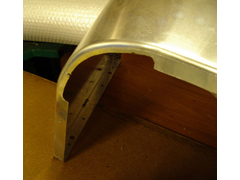

I know several people have suggested using rubber mallets to form sheet over into a smooth curved surface and that tools works pretty well but some

may want to try a leather faced wooden slapper to achieve the same results.

Here is a picture of Yours Truely shaping the outside curved surfaces of the McBearen fenders over a piece of 3" round stock using a leather

slapper. Works great and is very easy to achieve a uniform surface bend.

Dick Bear

[Edited on 27/11/06 by Dick Bear]

Rescued attachment Image56.jpg

C10CoryM - 27/11/06 at 06:13 PM

Thanks guys. I will let you know how I do when I try  .

.

Cheers.

.

.