Making a hole for the exhaust in the sidepanel?

Sideways 2 Victory - 16/5/03 at 10:38 AM

Hi guys,

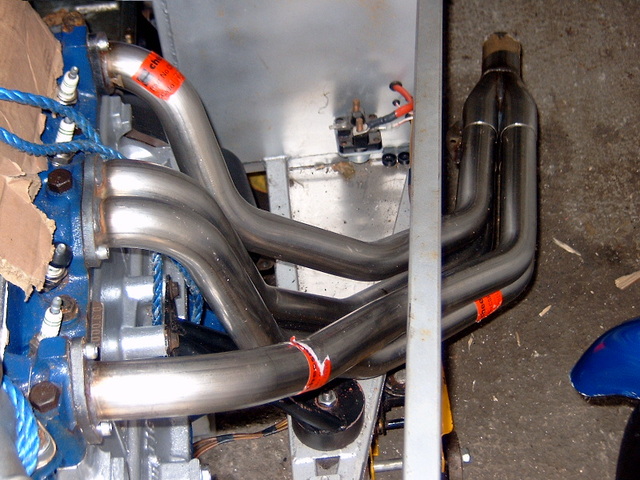

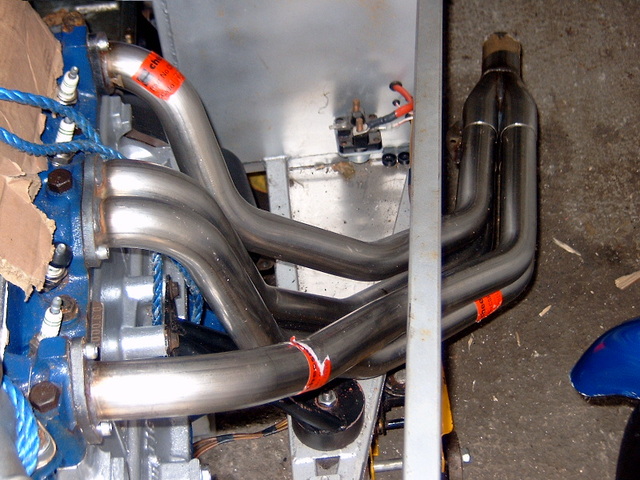

My next step is to refit my left hand engine bay side panel now that the 'zorst manifold and primaries are in place.

Any ideas on the best way to cut a hole in the sidepanel.

A:

How to judge where the opening needs to go (as u cant offer it up)cos the primaries are in the way.

B:

What tool is preferable for the cut? I figured drill small holes round perimeter and tidy up later?

(Note change of sig.)

Cheers

Dave

Rescued attachment s2300009.jpg

Viper - 16/5/03 at 12:21 PM

you could try a card board template, make a card board side panel, cut it in half through the middle of the primary and then just trim to fit, adding

or taking away bits till you got the desired hole, then just transfer the patern onto the real side panel..

tools air saw is good as is a dremel for fiberglass or a nibbler for ali, you can get ones that will fit an electric drill or operated by hand.

stephen_gusterson - 16/5/03 at 01:04 PM

machine mart do an hand nibbler for about 7 quid.

it makes little cuts about 6mm long each time you squeese the lever. You can cut holes and straight lines with it too.

atb

steve

kiwirex - 17/5/03 at 09:04 AM

I've got B&Q's cheapest jigsaw in the workshop and that claims to be able to cut metal.

- Greg H

Alan B - 19/5/03 at 12:03 PM

Hey Viper, that's a great tip!

So simple, yet I'd never though of that.

I've really struggled in the past making holes in panels for steering columns etc.

Big thumbs up mate, cheers..

Sideways 2 Victory - 19/5/03 at 02:06 PM

Yes thx Viper,

I shall try it and report back.

Cheers

Dave

Ian Pearson - 19/5/03 at 04:01 PM

I cut a hole in a piece of cardboard to suit my exhaust. I then taped it to the chassis and marked it so that I could re-position it. After having

removed the exhaust, I re-attached the template, offered up the side panel and traced the outline of the hole onto the panel. Worked well.

carnut - 19/5/03 at 06:28 PM

I have a similar but slightly more complex problem.

I have made and riveted on my ali side panel and need to get the exhaust made. The people who will make the exhaust need the car for the day to make

it. Would it be feasible for them to make the exhaust with the side panel on or should i drill out all my rivets (about 100)to remove it. Obviously

im reluctant to drill out all the rivets cos it takes time and may damage my side panel.

Any advise

Viper - 19/5/03 at 06:30 PM

Why not have a chat with the people making your exhaust, they might be able to cut the hole for you...

Jasper - 19/5/03 at 07:44 PM

Cut all my ali including tights radiuses with a regular jigsaw and a course metal blade, very neat and fast.

Ian Pearson - 19/5/03 at 08:31 PM

Used a fine blade with a little oil.

paulf - 19/5/03 at 08:51 PM

I use an air die grinder with a tungsten carbide burr in it to get the hole roughly to size and then finish off with a large dia flap wheel , one

nearly the finished hole size is ideal and gives smooth edges and a round hole. However remember that you will need to trim the edge with some rubber

or plastic trim to keep the SVA tester happy, so you can get away with some uneveness to the edge.

Paul.

quote:

Originally posted by Viper

you could try a card board template, make a card board side panel, cut it in half through the middle of the primary and then just trim to fit, adding

or taking away bits till you got the desired hole, then just transfer the patern onto the real side panel..

tools air saw is good as is a dremel for fiberglass or a nibbler for ali, you can get ones that will fit an electric drill or operated by hand.

elewayne - 23/5/03 at 03:30 AM

I have used nibblers before and they work really great. Air power is even better.

Jig saws can do a lot of damage in a hurry if any thing gets bound so be very careful.

Tape the bottom of the saw or it will scrach the ali.

I really like the nibbler best.