Mandril tube bending

pbs - 17/3/06 at 08:55 AM

Iam looking to get a roll bar made from mild or stainless steel. Does anyone know of any companies in the Kilmarnock/Glasgow area that can bend tube

using a mandrill?

ecosse - 17/3/06 at 09:17 AM

I don't know of anyone that can do this locally, maybe some of the other guys will though.

You could try http://www.mkengineering.co.uk/ not local but it won't cost much to get it

delivered up, thats where I'm going to be heading for mine.

Cheers

Alex

pbs - 17/3/06 at 09:37 AM

I have e-mailed drawings to MK engineering the other day, just waiting for a reply. Thought I would get another quote to compare prices.

iank - 17/3/06 at 10:11 AM

Think MNR also have the same bender as MK Engineering, might be worth pinging them for a quote.

http://www.mnrltd.co.uk/p_services_bespoketube.htm

marc n - 17/3/06 at 12:16 PM

yep we can bend stainless or cds / t45 tube, wouldnt recommend stainless on a safety front, if you use cds then the cage is rac approved if you ever

wish to race or compete in the future.

we dont supply rollcages in stainless or erw tube due to safety issues, if you want the shiny look go for cds chromed

best regards

marc

Avoneer - 17/3/06 at 01:10 PM

MK Engineering's expertise is in metal manipulation and isn't on computers or replying to emails - and he always in his workshop anyway.

Best way is to ring him.

Parts and products are superb and very good value.

I keep going back for bits from him rather than anyone else.

Pat...

pbs - 17/3/06 at 01:51 PM

quote:

Originally posted by marc n

yep we can bend stainless or cds / t45 tube, wouldnt recommend stainless on a safety front, if you use cds then the cage is rac approved if you ever

wish to race or compete in the future.

we dont supply rollcages in stainless or erw tube due to safety issues, if you want the shiny look go for cds chromed

best regards

marc

E-mail on the way Marc.

Fred W B - 17/3/06 at 01:55 PM

quote:

we dont supply rollcages in stainless or erw tube due to safety issues

Hi Steve

As a matter of interest, what wall thickness tubes do you use, in T45?

And not using stainless, is the problem the rigidity, as the UTS should be fine?

If I wanted to use stainless, and went up on the thickness, what would you reccomend?

I have access to a fully equipped tube bending/fabrication shop, but it's exclusively stainless

Cheers

Fred W B

[Edited on 17/3/06 by Fred W B]

marc n - 17/3/06 at 06:02 PM

yep got your mail will price up tomorrow for you

best regards

marc

marc n - 17/3/06 at 06:08 PM

quote:

As a matter of interest, what wall thickness tubes do you use, in T45?

1.67mm wall t45 compared to 2.67mm wall cds

quote:

And not using stainless, is the problem the rigidity, as the UTS should be fine?

most people who bend stainless do so for exhausts so the wall is 1.5mm and of course the tube is seamed, which with the whole weight of the car

resting on it if you did roll over would probably fail around the weld due to dissimilar metals being joined unless of course you have a stainless

mounting foot to bolt to the chassis, to be safe i would go to 2.5mm + wall and weld to 4mm / 5mm plates to bolt to the chassis

best regards

marc

Fred W B - 18/3/06 at 10:17 AM

Thanks Marc, sorry I called you Steve

My plan was to use stainless schedule 10 pipe (2.77 mm wall) so you have confirmed my thinking

Cheers

Fred W B

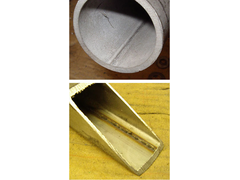

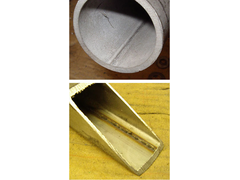

907 - 18/3/06 at 12:36 PM

Hi,

I've used 1.5" Sch 10 (48mm o/d) for my roll bar Fred.

I can't see a problem as I'm not going to race it.

I don't see a problem with welding steel to stainless either if the right rods (309) are used.

I do it all the time at work on coded vessels.

Also, there is more than one method of welding seams in hollow sections.

Below are a couple of pics. The box section is erw, the pipe is plasma welded I believe,

a "key hole" welding process. Quite a difference.

Just my 2p

Paul G

Rescued attachment ss-weld-seams.jpg