Rescued attachment ShineyScuttle.jpg

does anyone one have any pics or advice on the best way to make your own scuttle

I made a frame using 25x25 for the base, and 13x13 for the 'hoops'. I stretched the ally over the top, tensioned it with ratchet tie downs,

folded over the base and riveted. I peened over the lips and rivetted the hidden edges of the hoops. (I welded some 18g steel onto the firewall part

of the scuttle before starting the allywork for strength)

Rescued attachment ShineyScuttle.jpg

Getting the ally nice and even took a bit of effort, several clamps and cheap ply to stop any damage

Rescued attachment ShineyScuttle2.jpg

How about some ideas/Pics to finish off the edge facing the driver. I tried bending it round a pipe support, the next try was over flat bar and finishing off with the pipe, but it looks like S..T. Especially when the dash looks like ZETEC's dash.

I did the same way as the front

Rescued attachment ShineyScuttle3.jpg

Sorry, Still can't figure out what you did on the bach (Dash side). Did you "V" the ali and riveted it from the bottom? My dash needs

to be about 50 mm deep to the edge of the scuttle.

Must say it is a beautiful scuttle. I want my car with the minimum plastic.

I didn't V the edge, I folded it with a flipper which does not stretch the ally as you fold it, a bodyfile would do, or a bit of hardwood and a

hammer at a push.

The pic shows how it was done

Rescued attachment ShineyScuttle4.JPG

your scuttle looks excellent but i cant see where the bonnet fits onto it to keep it all looking level

Very nice, Mark, and I hope you can stand a few more questions:

1. How did you bend the square tubes for the hoops?

2. I would like to have an overhang at the dash to shade the instruments somewhat, which would involve bending a sheet with a rolled edge (ideally).

Got any pointers for doing this?

3. Do you think adhesives would handle the job on front and rear edges? With a rear overhang, I'd have to bond the skin to the hoop, I

think.

4. Do you have any pics of the scuttle before panelling and before adding the lip for the bonnet? I'm having trouble getting my mind around

what forms the support for the lip for the bonnet.

Thanks,

Pete

I think I will have to do a pdf on how I did it all, bear with me, should be ready later tonight

for some reason, I cannot attach the pdf to the post, if anyone wants it, post up you email address and I will send it out

I never have had problems before, but the pdf is a little over 500kb, perhaps ChrisW has set a limit on size? I will try zipping it

see if this works

thanks for that it will be very ussful

Thanks very much for taking the trouble, Mark! Your write-up cleared up my biggest mysteries.

Looks to be a lot less trouble than the couple other metal scuttles I've seen, though I'd probably try to find someone to bend the tubing

for the hoops.

Thanks

Your initial reply ended up being " A ROD FOR YOUR BACK"

wow Mark, that was very detailed, thanks! strangely enough, I went down a similar path with thin guage steel, which warped when welded, did that ages

ago. Now the project is finishing, I am using filler to even it up then I will skin with ali, prolly pu'd to base, rivted to underside of rails

to hide.

If Ron's book had been this detailed....I haven't looked at mine in months, I come here if I need suggestions!

Tim

Here's how I built an ali skinned scuttle w/o a steel panel underneath. Both the scuttle itself and the ali skin is removable (overkill I know),

in the book style:

http://www.7builder.com/Gallery/ScuttleAndDash/html/ScuttleLeadingFlange.html

The same idea would work with the hoop/flange arrangement Mark used. Obviously the retaining bolt could have been hidden, I left mine visible because

I use the same bolts on the body sides and to attach the front wings - continuing the theme.

My work isn't as pretty as Mark's, but the technique is pretty simple. HTH!

The edge facing the driver is still my concern. It needs lo look FINNISHED

What is a "ALI FLIPPER" ?

A flipper is a piece of spring steel, bent into a shallow s shape, file cut on one side, and handle at the other, you use it like a panel beating

hammer, very controllable and no stretching of the work.

The rear edge of the scuttle is finished by the dash

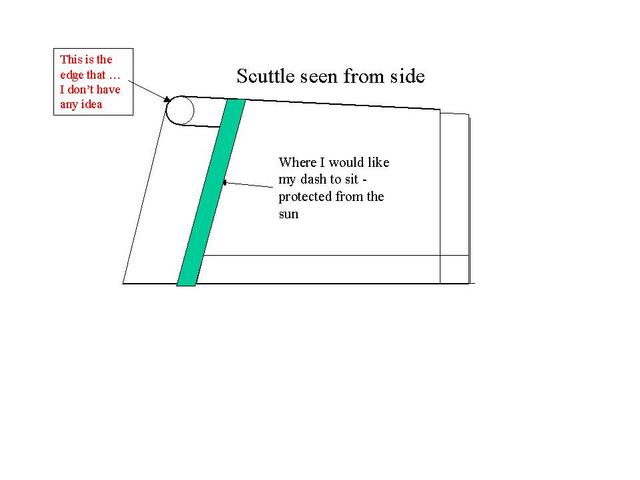

Rescued attachment ScuttleDashFinish.JPG

I need my dash panel to sit about 50 mm deep in the scuttle, so the dash can not finish the edge of the scuttle off.

Rescued attachment Dash Position.jpg

An edge like that is very do-able, but tricky. You might end up wasting a bit of ali till you get what you want. If you can, try doing it in 22g

instead, then you can attach it with spot welds and finish it with hammer and bondo - a nice finish in bare ali will be pretty tricky.

To bend around the tube, you need to clamp it as tightly as possible on the top edge, then gently encourage it around with a soft (plastic) hammer.

Hammer from the start of the curve (top) and smooth it down, it'll stay tight against the tube. You'll need to anneal it a few times to kee

it soft, and you'll probably have to end at the bottom of the tube - that straight section to the dash will be tough.

It'll wrinkle in a fashion similar to tucks, you need to hammer them out to shrink the ali - check one of the metal shapers sites for

"tucking" to get the technique.

Another idea, like Pete mentioned, is a wired edge, like u can see here:

http://www.7builder.com/Gallery/Bodywork/html/AliFrontQuarterRolledEdge.html

Again, the metal shaping forums are a good place to start for tips. If you do this, you need to figure out a different way to hold the skin on - glue

it to a steel skin like Mark, or provide a gluing or riveting surface on the top of the tube at the front and rear hoops.

I'm sure the rest of the guys will have some better ideas, hopefully these'll get you started thinking. Good luck!

quote:

Originally posted by kango

I need my dash panel to sit about 50 mm deep in the scuttle, so the dash can not finish the edge of the scuttle off.

I'm interested in this, too. Any likely problems with gathering at the inside corners?

quote:

Originally posted by pbura

I'm interested in this, too. Any likely problems with gathering at the inside corners?

How thick is 22g in mm. I grew up in the metric age.

quote:

Originally posted by Mark Allanson

quote:

Originally posted by pbura

Any likely problems with gathering at the inside corners?

Only if you try and tease it around the hoop, use a full arm swing and slam it!