Rollcage mockup - front hoop angle

rb968 - 8/2/12 at 10:24 PM

I have been having a go at mocking up a Rollcage for my MK and was wondering what angle the front hoop normally sits at? To my eye about 25degrees

looks about right.

Below are my attempts in waste pipe. I am looking to take the front hoop outside the cockpit rather than do the double bend and have it right next to

my knee. There is little room there for my knee as it is.

RB Rollcage mockup1

RB Rollcage mockup2

P.S. I am not ever intending to race or compete in my car and whilst I know I could go to MK or Procomp I have an expert fabricator and welder to

assist me fit the cage so fancy having a go at doing it myself.

Oh and it won't be made of 40mm wate pipe!

Rich

mark chandler - 9/2/12 at 12:15 AM

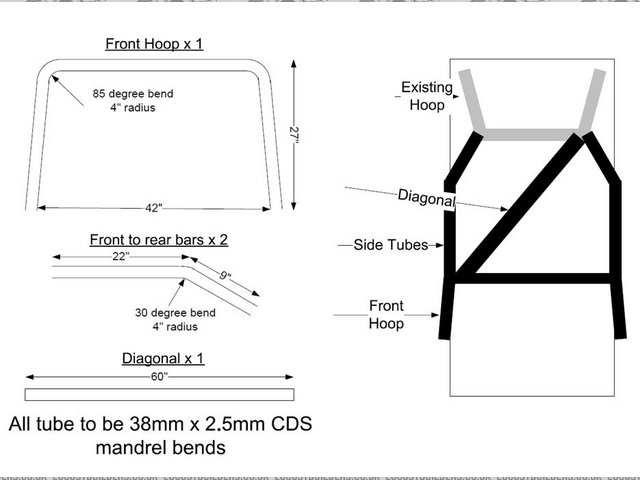

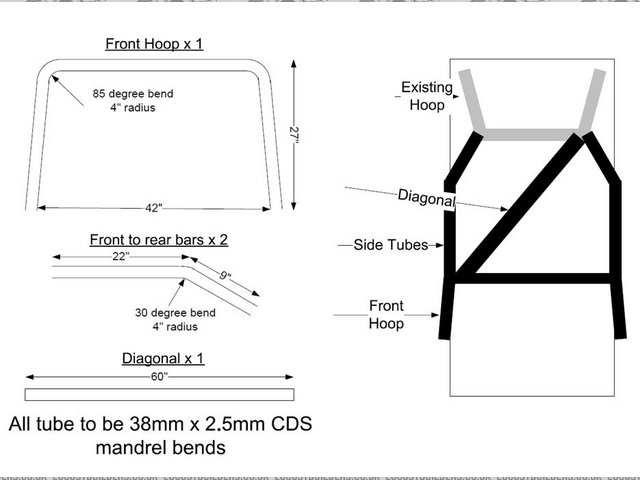

Here's mine

Cage NSF

I welded a bung in the join of the tubes at the top of the frame, then welded a capped bit of tube at the foot of the front hoop and ran a bolt

through to the inside.

few more pics

Cage front

Cage mounting

For tube my rear hoop is to MSA standards, 2", the front is 1.5", I measured up what I wanted then purchased pre bent off an Ebay seller as

a flat pack which worked out to be cheap, the front hoop, bent side bars and diagonal were £155, I made the rear hoop when I constructed the car.

You need to call around and batter them down in price, some people wanted double this !!!

Then 2 hours later all welded and painted

I cannot remember the ebay name, however his email address is matt79@hotmail.com

Here are the drawings, this will fit a original book frame width wise, you may want to extend the side bars.

drawings

Hope that helps

Regards Mark

rb968 - 9/2/12 at 12:38 AM

Brilliant Mark. Many thanks for those. Someone on here recommended churpycheap on eBay so was going to try him as well.

Rich

lsdweb - 9/2/12 at 08:16 AM

Rich

I appreciate you're never going to compete, but I would strongly recommend building your cage (ROPS) to MSA standards - whilst the MSA take a lot

of flak, there is considerable technical expertise there and the standards have been reached after years of development.

All MSA regulations are

here

An MSA spec cage will , in my opinion, make the car safer in an accident and more valuable if you come to sell!

Love the 40mm waste tube!

Regards

Wyn

loggyboy - 9/2/12 at 10:29 AM

I would add more angle, not only does it look better (IMO) but in a high speed role, ive always felt the more angled it is, the less likely it is to

dig in. With an angle it will act more like a ski and divert the impact forces from deforming the top bars. I may be talking out my arse but in my

head it makes sence!

rb968 - 9/2/12 at 10:29 AM

Will have a good look at the MSA book drawings and we will try and follow that guidance. I have been looking at others cages to get the best

solutions. The welder/fabricator is incredibly pedantic so it will be built as good as we can make it.

Rich

rb968 - 18/2/12 at 08:37 PM

Just to update this, I also mocked up some side bars to give some side protection.

Rollcage side bar mockup

Then took all my measurements and ended up ordering the lot from tom@tube-bender.co.uk in 38 x 2.64mm CDS.

Should be here by the end of next week so started prepping so my welder can put in the mounting plates.

Drilled out the rivets on the rear arches and panel so this ready to come off, removed seats and inner panels so I could fabricate the reinforcement

for the front hoop mounts. These will have m12 bosses welded into them to take the bolt from the outside to secure the front hoop.

Front LH plate mocked up with 20mm box to be welded in as well.

LH front mount

Then the same the other side.

Both front mounts

Hopefully will have the plates and some more 20mm box for the rear backstays to mount to done tomorrow.

Rich

[Edited on 18/2/12 by rb968]

loggyboy - 18/2/12 at 10:28 PM

quote:

Originally posted by rb968

Then took all my measurements and ended up ordering the lot from tom@tube-bender.co.uk in 38 x 2.64mm CDS.

MSA regs state 45mm min dia.

Neville Jones - 19/2/12 at 12:46 PM

FIA says main rollover bar has to be 45x2.5 or 50x2, the rest can be smaller. MSA want it all the same. However, if a cage is homologated to FIA test

standard, the tubes can be anything, with a minimum of 32 od, with a minimum of 1.5mm wall thickness. rollcage trivia.

Cheers,

Nev.

rb968 - 19/2/12 at 06:24 PM

Will ask the engineers at work what the relevant strengths are for 45x 2.5mm vs 38x 2.64mm CDS.

Thanks for the info gents.

Rich

loggyboy - 19/2/12 at 07:05 PM

quote:

Originally posted by Neville Jones

FIA says main rollover bar has to be 45x2.5 or 50x2, the rest can be smaller. MSA want it all the same. However, if a cage is homologated to FIA test

standard, the tubes can be anything, with a minimum of 32 od, with a minimum of 1.5mm wall thickness. rollcage trivia.

Cheers,

Nev.

USED to say the rest can be smaller, anything 'compulsary' post 95 has to be 45x2.5 or 50x2, its only optional (bracing etc) bars that can

be the smaller sizes.

As discussed many times, homologation is not a realistic option for the 'self builder' and if you getting a homologated cage, it needs to be

installed to that manufacturers approval and be marked etc as such.

On another note, if you dont plan on sprinting or racing the car, then MSA approval is largely irrelevant, however if it was me, I would ATLEAST do

the roll bar in 45 or 50mm.

[Edited on 19/2/12 by loggyboy]

Neville Jones - 20/2/12 at 09:32 AM

If you read what I wrote, I said FIA can be smaller, MSA wants all 45x2.5.

Got current/ latest/ most up to date FIA specs and testing procedure in front of me.

Cheers,

Nev.

loggyboy - 20/2/12 at 09:58 AM

quote:

Originally posted by Neville Jones

If you read what I wrote, I said FIA can be smaller, MSA wants all 45x2.5.

Got current/ latest/ most up to date FIA specs and testing procedure in front of me.

Cheers,

Nev.

So you did!

However the FIA have 2 sets of regs for 2012, one for a rollcage, and one for a ROPS. For some reason the Rollcage states 38 x 2.5 or 40 x 2 for the

whole structure - where as the ROPS requires larger for the rollbar - am I reading that right?

Neville Jones - 20/2/12 at 08:16 PM

The thing is, you can homologate anything if it is tested to FIA standards, as long as minimum tube sizes are met, and FEA shows no failures. This is

how people like Catervan and one company on here noisy about cages do it, along with the WRC people and the BTCC teams, and all the others. I've

FEA'd a cage for a se7en type car, made from 1 1/4" 2mm tube, and it flies through. Don't think I'd feel too safe inside it

though.

The cages I design for testing don't use cds tube, nor chrome moly. Good old DOM, as is recommended by USA regs and Aus CAMS regs. Odd that only

MSA ask for cheesemetal stretchy soft cds mild.

Roll cages don't exist anymore, they're all ROPS's.  Wait 'til the EU/EC or whatever they call themselves these days, get

involved!

Wait 'til the EU/EC or whatever they call themselves these days, get

involved!

Cheers,

Nev.

I use the Homologation Regs almost exclusively, so went back and had a look at Appendix J, Art 253 (FIA regs, not MSA)

Standard driver safety regs state Main Roll Hoop to be minimum of 45x2,5 or 50x2, and all other tubes 38x2.5 or 40x2.

Homologation regs just say no tubes under 32mm, and main hoop must be at least 1.5 thick, and all others 1.2. OD's depend on what you are

homologating. Material to be specified on the application. No aluminum.

[Edited on 20/2/12 by Neville Jones]

Ian-B - 20/2/12 at 08:54 PM

Remeber that DOM and CDS only refer to the production process and do not describe the mechanical performance, there are many grades of steel available

in a given production method, finished in various heat treatments. The different production methods will effect the mechanical propoerties of a given

grade of steel, although these differences are typically much smaller than possible by varying the grade of steel used.

Ian

rb968 - 11/3/12 at 06:22 PM

Rollcage Progress:

Thought I would keep a track of my progress on this thread.

Rollcage tubes all arrived from Tom at Tube Bender. Got the rear hoop tacked onto its plates then the rear backstays cut to length and the fishmouths

cut and fitted. Tacked the bottom plates on that will be used to bolt through the chassis plate in the rear. Used the tube mitre software to make

templates for the notches.

Rollcage rear hoop RB

backstay detail RB

Rear hoop side on RB

Then did the diagonal. Bit tricky as the tubemitre template is not much use when notching to join on the inside of the bend! Lots of filing later had

both ends sorted.

rollcage rear diagonal RB

Spent yesterday cutting the front hoop to correct height and then cutting the fishmouths in the bottoms of the 2 uprights.

Notched the ends of the roof bars today. Did the rear ones, can't do the front till the front hoop is in and then they can be cut down to the

right length.

Roof bars cut one end RB

So far so good. Ready for my mate the welder now to start replacing gaffer tape with metal!

Rich

alistairolsen - 15/3/12 at 09:42 PM

How much were the tubes?

on another note, what costs are associated with homologation, if you can present an FEA model? Is there a prescribed load case? (never seen the FIA

regs)

Cheers

rb968 - 16/3/12 at 12:18 AM

£400 for the CDs tube and bends. As for FIA homologation............I have no idea. My car is destined for spirited road use and the odd track day.

Rich

rb968 - 18/3/12 at 10:07 PM

Bit more progress on the rollcage.

Welded some 20mm box section to support the rear plates for the backstays. Tacked the plates on ready for final welding.

Tacked more box section and the plates into the chassis for the front mount. M12 boss welded into the plate to take the bolt.

Tacked the tubes to mount the front hoop to the plates.

This is what it looks like now. Next job now the front hoop is in is to cut the roof bars to length and notch them ready to be welded.

Getting there. Should be welded up by the end of next week hopefully. Just the sidebars to cut as well.

Rich

rb968 - 31/3/12 at 09:29 PM

Finally rollcage is welded. My mate from work came and kindly spent a few hours welding the chassis plates then the whole cage together. It was all

prepped and tacked but still took him 3 hours. Great job as well.

Spent 2 hours with a grinder taking it back to bare metal today......

Etched primed (starting with the underside) then 2 coats of primer.

Tomorrow it gets painted then I can start rebuilding the car! Just in time for the colder weather ;-(

Just seen the forecast........frosty and snow next week!!!!

Rich

rb968 - 1/4/12 at 09:41 PM

Finally painted with Simoniz tough black. Fitted back on the car. Hopefully will get it back on the road next week.

Got to relocate the fuel pump first and put rear bodywork back on.

Rich

AllWeatherDan - 19/4/12 at 01:10 PM

Looks Ace

Well Done