IM thinking about making a one off nosecone.

It will be 7 inspired with a few of my own little touches.

What are my options about going about this?

My thoughts at the minute are modify one or make a mould and make one myself.

So 2 questions really.

How easy is it to modify a GRP nosecone

OR how easy is it to work with GRP from scratch and making a mould etc.

Thanks

Mikkel

It's a doddle if a little messy but if you only want one nosecone then I would say best bet is to modify one rather than make a plug then a mould

then make a part from the mould...lot of work that.

i'd start with a nosecone and modify it, it lot easier than making a buck from scratch and then making amould

This might help

http://www.georgecushing.net/Nosecone2.html

Whats the process for cutting and shutting, for example, widening?

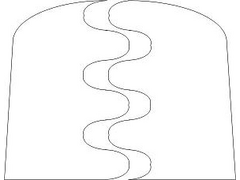

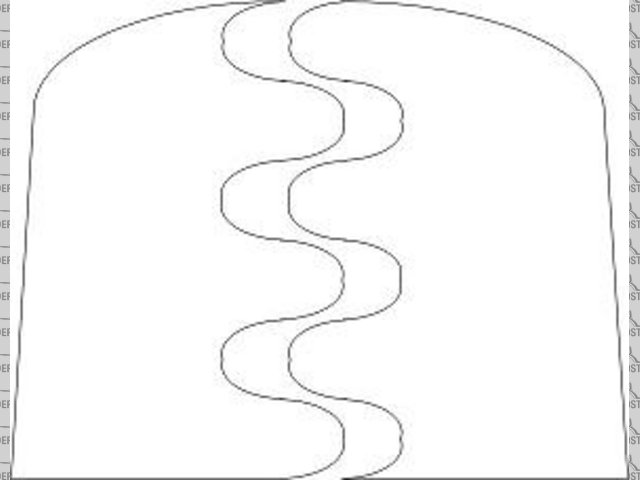

No straight lines!

If you widen cut a wavy line, this extends the join area and stops you getting a ridge, if you are adding 2" in width then 3" waves.

Next get some bits of wood and screw the two bits together to the new width, duck tape over the gap and backfill with fibreglass.

Rescued attachment cutnshut.jpg

A couple of years ago someone posted a thread about widening wheel arches but i cant find it

I remember they used a cornflake box in the process.