Have a look at this, may help:

Carbon Mods Video

I was just about to post a thread on this link (may still do

)

)

I've almost finished making a body panel but it's been hacked about so much that it weighs about 3.5 tonnes because of all the filler.

I've decided that it is now a buck so I'll take a mould from it and remake the pannel from the mould. The surface is almost entirely filler

and will be sanded nice and smooth.

How do I make a mould? Gel coat and GRP, but how much? How do I prepare the buck's surface? Wax? How many coats of wax do I need to guarantee

separation?

Thanks in advance for any useful suggestions.

You need some carbon

Have a look at this, may help:

Carbon Mods Video

I was just about to post a thread on this link (may still do  )

)

Good vid, now let me see what I can make! Litle lad will be the first at school with a carbon lunch box!

Why did he do so many layers in one go? Surely it would have been easier to do the first, let that cure then do the others. That way he'd have

known the top outside layer was completely pushed into the corners. I'd have used glassfiber for the inside layers too.

Also is there much in a loss of strength when not curing these mouldings in the usual vacuum bag, autoclave setup. GRP never seems to need this

treatment, why is it just carbon???

Fozzie? You do this stuff all the time, can you shed some light on this?

[Edited on 16/12/08 by Mr Whippy]

First you have to make sure that the mould can actually come off the plug..say for instance you moulded have a ball but went too far round then that

wouldn't come off..5 or 6 wax coats then pva to make sure it doesn't stick but no quarantee it won't especially taking mould from

filler.

Best option is to paint or laquer then wax etc.

CF needs vac bagging to ensure the resin is forced into the material and all air is removed because you can't really go at it with rollers as

distorts the weave. Too many layers in one hit will create too much heat and distort the mould and the part.

Gel coat then put too layers down making sure it's ALL down, let it cure then gritty paper to key it then start all over again with the resin...4

o 5 times the thickness of the part you intend to make but thicker the better for moulds if you want them to last.

Easy really

For making a mould, vacuum bagging is overkill. Simple GRP hand layup is sufficient for the sort of parts we might make. If you need to chase the

highest mechanical properties, and minimal weight, then vacuum bagging, infusion, prepreg etc come into play.

To make a mould, start off thinking about any flanges etc you need to add. Also think about the draught angle (release angle) - minimum of 3degrees is

good. It is best to add those to the buck now, before you get going. Once you have added these, use plastercine to radius any nasty corners, then you

are ready to start....

Seal the surface to ensure it is not porous - wax can help here, alternatively PVA solution works well. Once you have at least 5 coats of wax put on,

and buffed off, try an adhesion test - stick some masking tape to your released part (it shouldn't stick at all).

Next, apply your gelcoat (tooling gel, or gelcoat + wax solution). this needs to go on in 2 even layers - don't be tempted to wack a load on at

once. Once this has gone off, I would look at using a fine glass tissue, or very lightweight csm to back up the gelcoat. This will help stop

'print through' from the other materials. Once this has gone off, begin layup of your csm. I like to work with 450gsm - any more and it wont

take a radius without a lot of work. For your first layer, apply resin to the part, then add the mat, then work the resin up through the mat. Pay

particular attention to radiused corners, flanges, edges etc. Then continue to build up thickness, but not too much at once. If your part exotherms

(excess build up of heat caused by the reaction), then you can end up with an awful surface finish (pre-release), or even a fire!

Once you have built up sufficient thickness, you would need to add some support/stiffeners to your mould. USe steel, or wooden battens, and brace the

backside of your mould. Again allow it all to go off. Once it is good and hard, you can look at demoulding the buck from the mould, and admiring your

handywork....!

I once left a glass bowl full of unused resin, got so hot it started steaming and shattered the bowl, didn't catch fire but made heaps of

volcanic like noise

Good wee video... never realised it was that straightforward... !

Does anyone have a good vid for larger GRP laying techniques?

Should I use polyurethane varnish on the filler, then wax then PVA? I've used varnished and waxed MDF to good effect before. Never on filler though.

quote:

Originally posted by Mr Whippy

Why did he do so many layers in one go? Surely it would have been easier to do the first, let that cure then do the others. That way he'd have known the top outside layer was completely pushed into the corners. I'd have used glassfiber for the inside layers too.

Also is there much in a loss of strength when not curing these mouldings in the usual vacuum bag, autoclave setup. GRP never seems to need this treatment, why is it just carbon???

Fozzie? You do this stuff all the time, can you shed some light on this?

[Edited on 16/12/08 by Mr Whippy]

Hi All,

I made a mould for a nose cone as the ones you can buy here in SA are really not good. I would advise against waxing directly on to body filler, far

better to use 2K primer followed by top coat. On the plug for the nose I flatted the 2K with 1200 to give a smooth uniform but flat finish.

Whilst the mould released from the plug it wouldn't come off because of the shape, so eventually I had to split the mould to get it off the plug.

I ended up with a nose that I'm more than happy with. As a release agent I used Meguiars mould release wax, 8 coats allowing the wax to dry

completely before buffing, worked a treat.

Ross

Smart51 .... Perhaps this will help you get started.

Here's how I did it for a part I made (nothing to do wit a car)

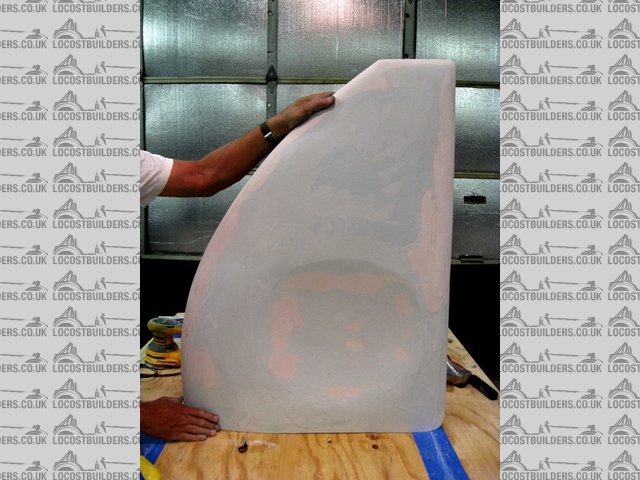

Bondo buck ... created over simple cardboard rough form sanded smooth and to correct shape.

Dick Bear

[Edited on 12/16/0808 by Dick Bear]

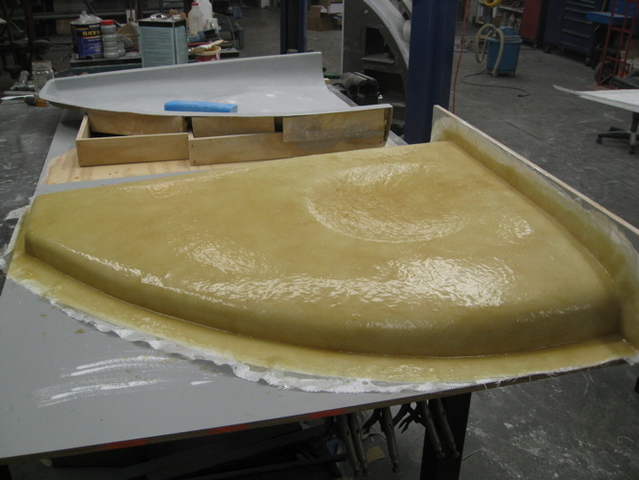

Rescued attachment Bondo buck.jpg

#2

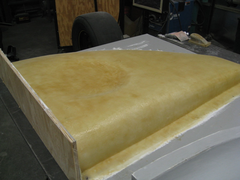

Laid-up fiberglass and fiberglass pad over the buck

Dick Bear

Rescued attachment fiber mold 1.jpg

#3

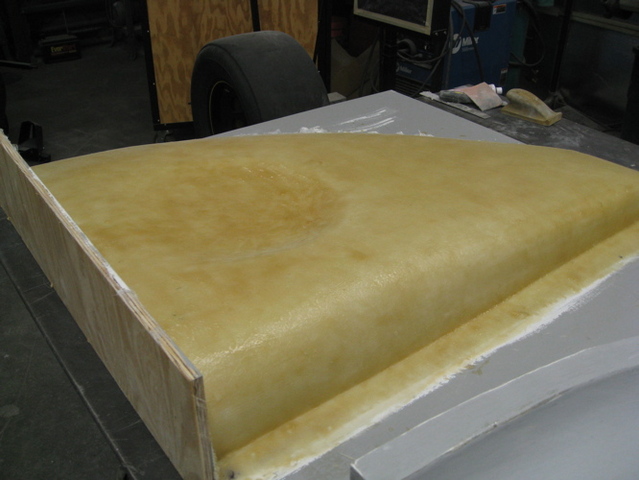

Same image but on the unit in the back you can see the bracing I bondo(ed) to the mold to hold its shape.

Dick Bear

Rescued attachment fiber mold 2.jpg

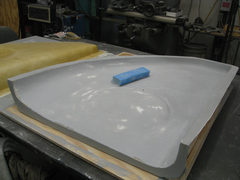

#4

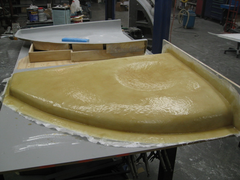

Turning the mold right side up and filling, sanding and preparing the surface smooth .... gel-coat, and release etc.... ready to lay-in fiberglass for

the part.

Dick Bear

Rescued attachment Ready mold.jpg

#5

Primer painted finished part.

Sorry I couldn't figure out how to place more than a single photo per post.

Dick Bear

Rescued attachment Primered part.jpg

quote:

Originally posted by Mr Whippy

Why did he do so many layers in one go? Surely it would have been easier to do the first, let that cure then do the others. That way he'd have known the top outside layer was completely pushed into the corners. I'd have used glassfiber for the inside layers too.

[Edited on 16/12/08 by Mr Whippy]

quote:

Originally posted by fesycresy

You need some carbon

Have a look at this, may help:

Carbon Mods Video

Hi,

Can someone help me by telling me how to upload images as attachments?

ross

quote:

Originally posted by Ross SA

Hi,

Can someone help me by telling me how to upload images as attachments?

ross

Thanks, I'll give it a go.

Ross

Ok,

I clicked on the browse button and it opened up my pictures, I selected the image I wanted to load but I didn't see an "OK" to

click.

Ross

Sorry, the button is called "Open" not "OK".

Thanks, I'll try again.

Cheers,

ross

It looks like it worked this time, this is a picture of my nose cone.

Ross

Nope still no luck!

Hi Ross

Nice to see you here. I also battled with pics, now i upload them into my archive here, and then right click the "properties" of the image

into the block that appears when you click the "add image" block in your post

It helps to have the website open twice in two windows

Cheers

Fred W B

Hi Fred,

Thanks for the input, my problem is that me and uploading stuff just don't hit it off. Maybe you could tell me how to update my profile? Cheers

from hot and sunny SA.

Ross