Basically I need a blend between a 50mm round inlet to twin 35+33mm outlets, over a distance of about 70mm.

I have Corel Draw so can export in whatever you need to get started. Any help would be appreciated - it seems I am only ok with 2 dimensions

I am trying to get my head round a 3D model and I am going to admit defeat. Can anyone do a quick 3D model (DXF probably) so that I can get my inlet

manifold machined?

Basically I need a blend between a 50mm round inlet to twin 35+33mm outlets, over a distance of about 70mm.

I have Corel Draw so can export in whatever you need to get started. Any help would be appreciated - it seems I am only ok with 2 dimensions

How far apart are the centres of the 33mm & 35mm ports ?

My weapon of choice is Autocad with Xtube.

Maybe one of the solidworks experts could also help out with this.

[Edited on 10/10/10 by zilspeed]

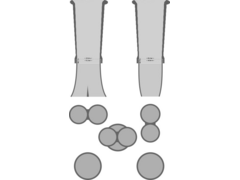

Here's a pic of the 2D file

LIM & Trumpet

Looks like some of the dimensions didn't make it - I already have the trumpets so the blend is the only thing left to do. I can then duplicate it

and paste it onto my baseplate ..... all in theory of course

[Edited on 10-10-10 by RazMan]

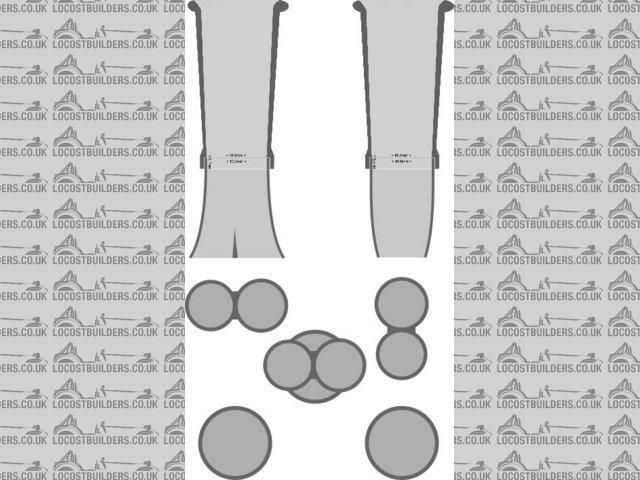

Here's another pic if its any help

[img][/img]

What software are you using?

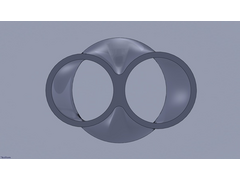

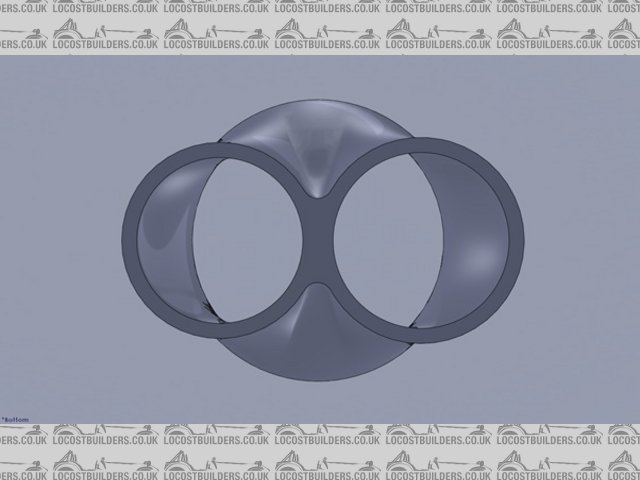

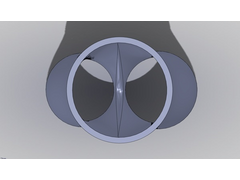

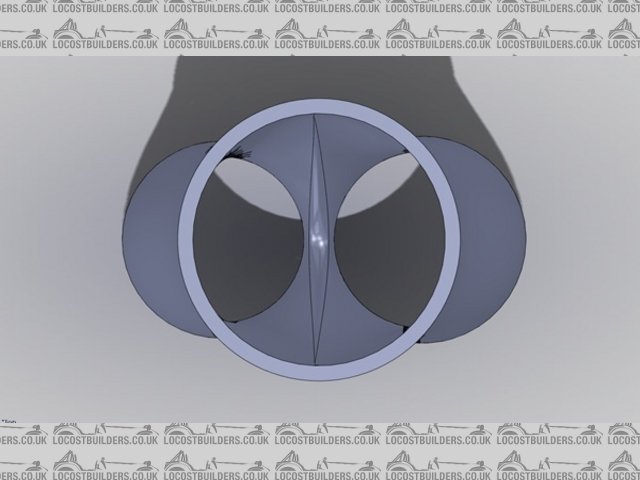

I've drawn something, not sure if it's what you're after.

If you PM me email address i'll send some pics and a quick description.

Deleted mine because it was rubbish compared to the one below.

[Edited on 10/10/10 by zilspeed]

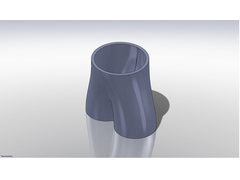

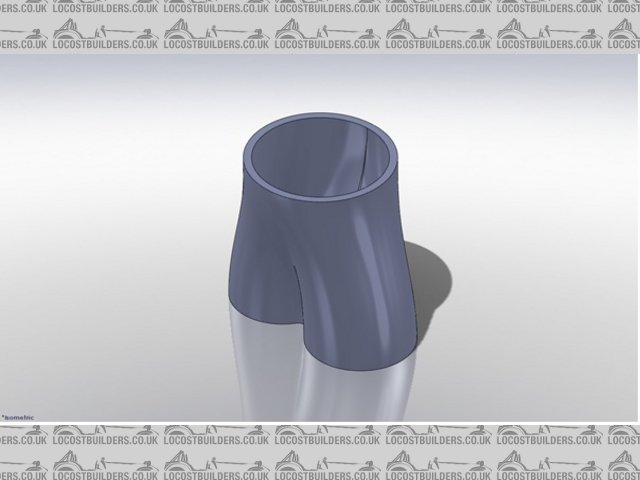

Description

inlet thingy bottom

inlet thingy top

That's much more like it.

Well done sir.

Bloomin' heck! I've been messing about for hours and you come up with EXACTLY what I am after in a few minutes!

U2U coming your way

LOL

It's only easy if you know how.

Simply, loft the out side, then two lofted cuts for the runners.

Play around with the constraints and such until it is's right.

The wall is 3mm at entry and exit.

Are you after some sort of flange to join to the head?

I'd prefere not to give you a model that you use, as if it's not right you won't be happy, and i'm guessing it's not cheap tp

get one made. Also, my skills fall a little short in terms of CIM.

I'm more than happy to give you/anyone the model, and i don't mind if you do use it, as long as you understand it took about 5 mins with

very little consideration.

I'll give it another look, might be able to do a little CFD if i get chance (probs not today as i've got something important on Monday)

although there's very little such a simple design could be improved.

Holy crap!

You can see why he's called 'brianthemagical'.

'cos he knows everything and can do magic as well.

quote:

Originally posted by Confused but excited.

Holy crap!

You can see why he's called 'brianthemagical'.

'cos he knows everything and can do magic as well.

quote:

Originally posted by brianthemagical

LOL

It's only easy if you know how.

Simply, loft the out side, then two lofted cuts for the runners.

Play around with the constraints and such until it is's right.

The wall is 3mm at entry and exit.

Are you after some sort of flange to join to the head?

I'd prefere not to give you a model that you use, as if it's not right you won't be happy, and i'm guessing it's not cheap tp get one made. Also, my skills fall a little short in terms of CIM.

I'm more than happy to give you/anyone the model, and i don't mind if you do use it, as long as you understand it took about 5 mins with very little consideration.

I'll give it another look, might be able to do a little CFD if i get chance (probs not today as i've got something important on Monday) although there's very little such a simple design could be improved.

Brian, that is soooo close to what I have been trying to do all afternoon. I would be

really chuffed if you can do anything in this area - my 2D skills are ok but I'm a real numpty when it comes to 3D. I will send you my baseplate

drawing and if you could somehow (magically?) put the two together I will be forever in your debt.

Brian, that is soooo close to what I have been trying to do all afternoon. I would be

really chuffed if you can do anything in this area - my 2D skills are ok but I'm a real numpty when it comes to 3D. I will send you my baseplate

drawing and if you could somehow (magically?) put the two together I will be forever in your debt.

I am not sure what thickness the baseplate needs to be - 6mm? 10mm maybe?