ditchlewis

|

| posted on 17/2/08 at 11:49 AM |

|

|

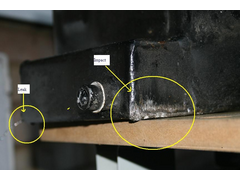

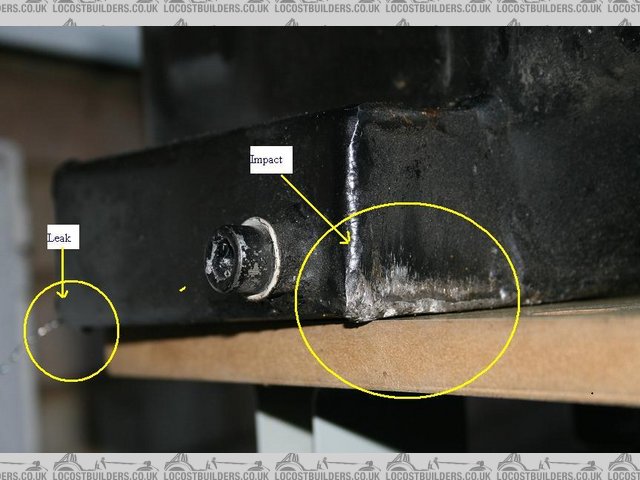

sump repair and protection

well i took the sump off yesterday and contary to my beilief there was little damage, and no dents. the pictures below show the scratching and the

leak at the back of the sump.

the hole at the back was fixed in 5 seconds with one spot weld

i'm proposing to weld a skid plate to the bottom of the sump . i've had problems finding 5mm plate and have brought 1mm plate. i propose to

weld 4 pieces together and them mount the plate to the sump.

i'm going to drill holes in the plates and then spot weld them to gether.

should i

A drill holes through all the plates and then spot weld direcly onto the sump with some stitch wealding at the edge

or

B drill holes through 3 of the 4 plates and then stitch weld onto the sump at the edge?

i want to minimise any possible warping?

ditch

Rescued attachment sump plate.JPG

|

|

|

|

|

ditchlewis

|

| posted on 17/2/08 at 11:52 AM |

|

|

and more pics

Rescued attachment sump.JPG

|

|

|

ditchlewis

|

| posted on 17/2/08 at 11:54 AM |

|

|

and another

Rescued attachment IMG_8776.JPG

|

|

|

Litemoth

|

| posted on 17/2/08 at 12:03 PM |

|

|

What about a Kevlar or plastic option?

Link Here

|

|

|

ditchlewis

|

| posted on 17/2/08 at 12:06 PM |

|

|

i had thought of that but monies tight and the weather is so good i just want to drive and cant wait to fix it

ditch

|

|

|

tks

|

| posted on 17/2/08 at 12:26 PM |

|

|

mhhh honestly best thing you can do is weld in an extra chasis bar just 1mm lower as the sump itself... from there on a sheet of anything to the

sides.

what are you trying to archieve??

you can beef up the sump but then the impact will be taken by the next weekest spot....

best bet IMHO is some glideing plates untherneath the car... sow the car skids.../glides... instead of impacts..

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

ditchlewis

|

| posted on 17/2/08 at 12:52 PM |

|

|

the problem is that the engine sits 50mm below the chassis rail and 75mm above the ground

there is also not much room to raise the engine unless i have new engine mounts.

while i know that this is not a perfect solution it's the best prevention at the moment.

i have also thought of strengthening the sides of the sump with 5 mm bar.

the 4mm of plate will be a sacrificial plate i know, but i hope that is will skid rather than split.

the i will have to look at avoiding bumpy roads

ditch

|

|

|

tks

|

| posted on 17/2/08 at 01:25 PM |

|

|

if you want to absorb an impact then you should weld the plates in that way leaving air between them... in that way it will be a crash instead of a

chock...

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

nitram38

|

| posted on 17/2/08 at 01:33 PM |

|

|

Anything directly welded to the sump will cause tears in the sump if it catches.

What about a nylon skid plate fixed to the chassis?

|

|

|

thomas4age

|

| posted on 18/2/08 at 06:27 AM |

|

|

I've mounted a 5mm steel plate al the way under the sump, the plate gets abused a lot, but never had a leak or even a dent in the sump since.

try and locate a 5mm steel plate that would still be be the most simple solution even if it proves hard to get, though I'm sure someone on here

can help you with locating a piece.

Grtz Thomas

If Lucas made guns, Wars wouldn't start either.

|

|

|