ned

|

| posted on 24/6/06 at 05:49 PM |

|

|

removing morse tapers?

Another 'new pillar drill' related question..

I picked the drill up this morning, nice long round trip and have spent most of the afternoon taking bits off/cleaning it and refitting etc.

What I didn't realise is that the drill only has a 1/4" chuck on it which isn't going to be terribly useful and its on a no1. morse

taper (and there's no chuck key  ). ).

I managed to find a copy of the original specifications/manual on the web which shows it as a 1/2" capacity model, I also then checked the

make/model plate on my drill and it states it is 1/2" not 1/4" as per the chuck that is actualy fitted.

here's the original manual:

http://www.gandmtools.com/makerspages/fobco_star.pdf

here's a pic of my drill with the 1/4" chuck:

and here's a pic of another of the same make/model with a 1/2"chuck:

I know that I can get a 1/2" chuck for the morse 1 taper but it looks as if my drill has a sleeve/converter from morse 2 to morse 1, hence the

long bit sticking down that the morse one chuck is attached to. Does anyone think this is right and if so how do I remove it from the headstock so I

can fit a normal morse 2 chuck?

cheers,

Ned.

beware, I've got yellow skin

|

|

|

|

|

the_fbi

|

| posted on 24/6/06 at 05:51 PM |

|

|

There should be a long bolt going into the top of the taper, undo it a few turns and smack it on the head with a hide mallet. Then when its free of

the taper, undo the bolt and withdraw sleeve.

At least thats how we used to do them at college 15 years ago

[Edited on 24/6/06 by the_fbi]

|

|

|

owelly

|

| posted on 24/6/06 at 05:57 PM |

|

|

I can't see your piccies as my works 'puter shouts at me but have you pulled the quill down as far as it will go to see if there is a slot

in it? If there is, you need to turn the chuck to align the holes and knock a tapered drift in to release the morse. If yours hasn't, please

ignore me...........

http://www.ppcmag.co.uk

|

|

|

ned

|

| posted on 24/6/06 at 05:59 PM |

|

|

doctor who is just about to start but i'll take some piccies in a bit and you can tell me what i'm missing

beware, I've got yellow skin

|

|

|

daviep

|

| posted on 24/6/06 at 06:04 PM |

|

|

Morse tapers are not usually fitted with a draw bolt, normally just put the chuck down to it's lowest position and rotate chuck by hand and you

should see a slot which you drive a wedge into to remove the chuck.

Have a look here

sorry took ages finding link!!!

[Edited on 24/6/06 by daviep]

|

|

|

paulf

|

| posted on 24/6/06 at 06:45 PM |

|

|

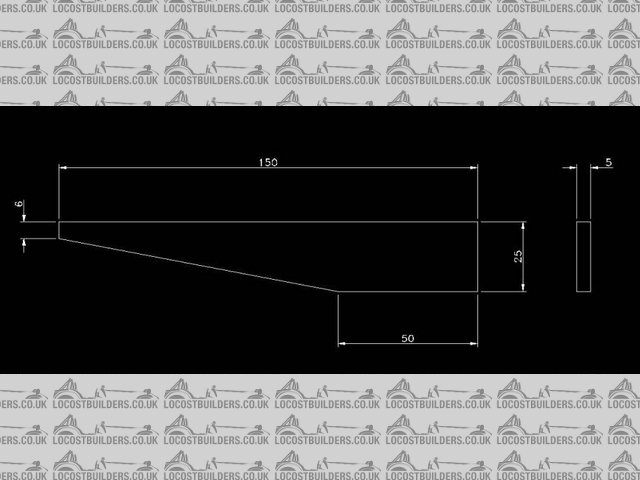

It is the exact same drill as I have and there is a slot in the spindle extension , there is no need to pull the spindle down it is there

normally.Make a taper drift from a bit of 6mm plate with a shallow taper from about 10mm to 25 mm over about 150mm long , this will then remove the

chuck easily. The correct drift could be bought from most engineering suppliers.

Although stated as 1/2 inch capacity I have used larger drills in mine with a little care in use.

Paul.

quote:

Originally posted by daviep

Morse tapers are not usually fitted with a draw bolt, normally just put the chuck down to it's lowest position and rotate chuck by hand and you

should see a slot which you drive a wedge into to remove the chuck.

Have a look here

sorry took ages finding link!!!

[Edited on 24/6/06 by daviep]

|

|

|

ned

|

| posted on 24/6/06 at 08:15 PM |

|

|

I can see the slot in the spindle extension, pic here so removing the chuck looks simple enough:

http://www.locostbuilders.co.uk/upload/IMG_2164b.jpg

but i thought the extension was removble aswell as the picture/manual of the same model drills with 1/2" chucks haven't had any extension

fitted?!

paulf is yours a 1/2" chuck on a morse 1 taper extension?

do you see what I'm getting at?

Ned.

ps here's another pic after cleaning it up a bit, I am yet to refit the depth stop and safety guard.

http://www.locostbuilders.co.uk/upload/IMG_2167b.jpg

pps daviep, good link - thanks.

[Edited on 24/6/06 by ned]

beware, I've got yellow skin

|

|

|

Mansfield

|

| posted on 24/6/06 at 09:04 PM |

|

|

Morse taper drill drifts usually look something like this. Mild steel okay.

Rescued attachment Image1.jpg

|

|

|

chris.russell

|

| posted on 24/6/06 at 09:14 PM |

|

|

That brings back lots of memories of my apprenticeship, making drifts, squares and the dreaded filing test!

Mines a pint

|

|

|

Mansfield

|

| posted on 24/6/06 at 09:18 PM |

|

|

Make something like the previous picture, and a sharp tap will remove it. Make sure you catch the chuck, you dont want to spoil a lovley little chuck

like that. Once you can remove the chuck at will, you will probably find you want to use it for small drills.

Drill drift http://cgi.ebay.co.uk/MORSE-TAPER-3-M-T-KEY_W0QQitemZ7630253940QQihZ017QQcategoryZ64812QQrdZ1QQcmdZViewItem

3/8" chuck http://cgi.ebay.co.uk/MORSE-TAPER-3-8-CHUCK-KEY_W0QQitemZ320000680679QQihZ011QQcategoryZ67240QQrdZ1QQcmdZViewItem

I have used a 1/2" chuck on a No.1 taper, they must be out there. Failing that, drill shanks can be turned down - they are generally softer

than the 'cutting part' of th drill.

|

|

|

paulf

|

| posted on 24/6/06 at 09:21 PM |

|

|

Mine is a no 1 morse taper and has a 1/2 inch chuck fitted , I also have a step up sleeve from 1 to 2 morse taper that I use for larger holes

occasionally.

Paul.

quote:

Originally posted by ned

I can see the slot in the spindle extension, pic here so removing the chuck looks simple enough:

http://www.locostbuilders.co.uk/upload/IMG_2164b.jpg

but i thought the extension was removble aswell as the picture/manual of the same model drills with 1/2" chucks haven't had any extension

fitted?!

paulf is yours a 1/2" chuck on a morse 1 taper extension?

do you see what I'm getting at?

Ned.

ps here's another pic after cleaning it up a bit, I am yet to refit the depth stop and safety guard.

http://www.locostbuilders.co.uk/upload/IMG_2167b.jpg

pps daviep, good link - thanks.

[Edited on 24/6/06 by ned]

|

|

|

Mansfield

|

| posted on 24/6/06 at 09:25 PM |

|

|

Did you also get the "sent to stores for a long stand" test ?

|

|

|

ned

|

| posted on 24/6/06 at 09:38 PM |

|

|

thanks for all your help guys. i still don't understand why the model pictured with a 1/2" chuck and the manual don't show the

extension that paul and I seem to have on ours - oh well just get a 1/2" 1 morse chuck and be done with it

thanks again,

Ned.

ps next i shall be mostly posting about 3 phase power again

beware, I've got yellow skin

|

|

|

Danozeman

|

| posted on 24/6/06 at 10:15 PM |

|

|

That is the same as the one we have at work!! Its brand new nd only came out a few weeks ago!! That has a 1/2 inch on it. Bloody good drill!!

Cant help on the chuck though i didnt fit it..

Dan

Built the purple peril!! Let the modifications begin!!

http://www.eastangliankitcars.co.uk

|

|

|

wheelfelloff

|

| posted on 25/6/06 at 11:29 AM |

|

|

Ned

Most reasonable drill chucks have a removable arbor. This is just a short self locking taper that goes into the chuck body and the other end is ground

to 1, 2 or 3 morse etc to fit the drill. They can be difficult to remove from the chuck end however and with the cheap rices for 1/2" chucks

these days I wouldn't bother.

You could also have an adaptor sleeve fitted into the spindle which is just 2 morse on the outside and 1 morse on the inside. if you have one of these

fitted when you replace the chuck it would be better to remove it as they increase the spindle overhang. For a new chuck look at ArcEuro Trade, or RDG

Tools Online, JL or any of the other importers. Most of the chinese stuff (tooling) coming in at the moment is reasonable quality.

Morse tapers are known for their difficulty in removing so a good drift as described above will be worthwhile. When you remove the chuck and adaptor

the spindle taper will let you use much larger drills that have morse taper ends, these can be bought very cheaply at car boot sales etc and are

reasonably easy to re-sharpen once you have the hang of it. With the adaptor you will be able to use parallet shank drills via the chuck, and 1 and 2

morse shank taper drills via the spindle and the adaptor. These are excellent drills and will no doubt last you several lifetimes.

regards

Keith

|

|

|