DEAN C.

|

| posted on 28/1/06 at 03:42 PM |

|

|

DIY/LOCOST Machinery plans

Hi,just had a thought which might get going.

Why not submit any non copyright plans on here for LOCOST , DIY tools and machinery etc.

Thoughts were plans for the following items:

Home built lathe (seriously I have seen these)

Milling /drilling machine

Garage waste oil heater/Pot bellied stove.

I have made these myself from HGV brake drums and have seen stoves made from car rims,gas bottles(I'll get flak about that)

Dust/fume extractors

Grit blasting cabinets.

Loads of other things can be DIY made.

Any thoughts to open this on a LOCOST theme?

Once I've finished a project why do I start another?

|

|

|

|

|

britishtrident

|

| posted on 28/1/06 at 04:03 PM |

|

|

Waste oil burning heaters are highly dangerous -- lethal they tend to explode hours after you think they are extingished.

Even when buring pure kerosene or gas oil "Salamder" type stoves can explode durring the cooling down period. The motor trade stop using

them for workshop heating over 40 years ago.

[Edited on 28/1/06 by britishtrident]

|

|

|

Mix

|

| posted on 28/1/06 at 04:03 PM |

|

|

I like this idea......a lot

Mick

|

|

|

dave1888

|

| posted on 28/1/06 at 04:30 PM |

|

|

I like the homebuilt lathe and miling machine idea.

|

|

|

ch1ll1

|

| posted on 28/1/06 at 04:38 PM |

|

|

sound like i need to make a big heater !

and make the wife stay there to make sure it cools ok !

|

|

|

liam.mccaffrey

|

| posted on 28/1/06 at 05:23 PM |

|

|

put "gingery" into google

Build Blog

Build Photo Album

|

|

|

DEAN C.

|

| posted on 28/1/06 at 05:27 PM |

|

|

Quote by British Trident:Waste oil burning heaters are highly dangerous -- lethal they tend to explode hours after you think they are extingished.

Even when buring pure kerosene or gas oil "Salamder" type stoves can explode durring the cooling down period. The motor trade stop using

them for workshop heating over 40 years ago. (End quote)

As a general state ment that is not true.

Waste oil heaters are a commonly available in lots of modern workshop and are no more dangerous than any other heating.

If you are referring to the salamander stoves then yes I agree having used one a few years ago in my own workshop at home.

Mine had an external flue unlike the old open flue jobs,and I must admit I took it out because I worried about leaving the garage afterwards.

The latest fan assisted metered pump waste oil heaters are excellent and definately not illegal,although technically you need a waste burning

licence,Ahem!!

At least four garages within five miles of my house use the modern type waste oil heaters in the workshops and I have never heard of any

problems,although I do know of one person being badly burnt locally with the old type about ten years ago in a garage I nearly bought a few months

before the incident(It could have been me!)

I was recently considering fitting two enormous waste oil heaters to our workshops but the consumption due to the workshop size would probably outrun

our 2000gallon/year approx oil waste.

(The workshop I run can easily hold 15-18 HGV's+a handful of Transit size vehicles for storage)

Regards, Dean.....

[Edited on 28/1/06 by DEAN C.]

Once I've finished a project why do I start another?

|

|

|

Wadders

|

| posted on 28/1/06 at 05:39 PM |

|

|

Some stuff here

http://www.green-trust.org/junkyardprojects/FreeHomeWorkshopPlans.html

here http://www.metalwebnews.com/howto/tube-bender/tube-bender.html

and here http://www.roddingroundtable.com/tech/articles/12ewheel.html

should keep you going for a while

|

|

|

rusty nuts

|

| posted on 28/1/06 at 06:55 PM |

|

|

Modern waste oil heaters don't like synthetic oil as it leaves a deposit like burnt plastic . Had this with a new heater and it wasn't

covered by warranty . No mention of this in the instruction manual ! We very often had cars in with incorrect fuel , the cost of disposal was very

near the cost of the fuel in the first place . We used to mix 5lts of mixed fuel to every 50 lts of waste oil with now problems

|

|

|

Mansfield

|

| posted on 28/1/06 at 07:21 PM |

|

|

Dont you need a lathe and a milling machine to make a lathe and a milling machine?

|

|

|

Peteff

|

| posted on 28/1/06 at 07:29 PM |

|

|

Yes

and a home foundry. Here's some plans for a heater I have in

my favourites . You need an old boiler to build it though, and I don't mean the mother in law  . .

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

cossey

|

| posted on 28/1/06 at 07:49 PM |

|

|

if you follow the gingery series then you need a small foundry to cast aluminium to make both the lathe and the mill.

the lathe must be made first and the lathe itself helps make the finished lathe then the lathe is used to make the mill.

|

|

|

caber

|

| posted on 28/1/06 at 08:19 PM |

|

|

I saw the inside of a very large flame thanks to a Salamander! It was out, empty and I was refilling it and it flashed over, Thankfully I had glasses

on with welding overalls and a cap so no significant injury:-)

The following week the thing vomited flaming oil all over the workshop floor! The next week it was dumped outside never to be used again. Apparently

they are really well behaved if you feed them clean parrafin or diesel, They are still the heater of choice for outdoor applications such as tree

nurseries, they can certainly pump ut the heat.

Caber

|

|

|

907

|

| posted on 29/1/06 at 09:06 AM |

|

|

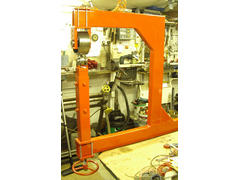

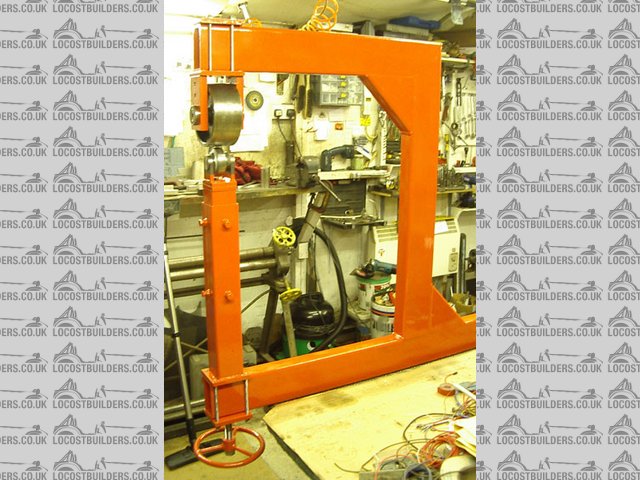

Home made tools

Hi,

I've made,

a pipe bender / hydraulic press,

pyramid rolls, (for can inner tubes & bodies)

1m sheet folder

English wheel

No drawings I'm afraid, but pics if anyone is interested.

It would take me as long to do drawings as it would to make the tool.

I'm useless with a pencil, and even worse with Cad.

Paul G

|

|

|

DEAN C.

|

| posted on 29/1/06 at 10:17 AM |

|

|

Hi,photos would be fine if you could link or attach from here.

Already we have have had lots of useful links to give people ideas.

Once I've finished a project why do I start another?

|

|

|

907

|

| posted on 29/1/06 at 10:59 AM |

|

|

Pipe Bender & Press

Rescued attachment Lotus 082.jpg

|

|

|

907

|

| posted on 29/1/06 at 11:03 AM |

|

|

Wheel

Rescued attachment Its-wheelie-done.jpg

|

|

|

907

|

| posted on 29/1/06 at 12:06 PM |

|

|

rolls

Rescued attachment tools-005s.jpg

|

|

|

907

|

| posted on 29/1/06 at 12:07 PM |

|

|

Bender

Rescued attachment tools-001s.jpg

|

|

|

Confused but excited.

|

posted on 4/2/06 at 11:45 PM posted on 4/2/06 at 11:45 PM |

|

|

Oy vey! Vot a vorkshop dis boy has.

Look ma, my eyes have gone emerald green.

Tell them about the bent treacle edges!

|

|

|

C10CoryM

|

| posted on 5/2/06 at 05:04 PM |

|

|

For anyone looking to get into banging out shapes in sheet you can build your own shaping/planishing hammer out of some square stock and an old air

hammer and a air valve. Make a frame similar to 907s english wheel frame but instead of the wheels mount the airhammer and an anvil (old hammer head

or something) Use an air flow valve and mount to a foot pedal.

Gets you something like this for about $30

http://www.tinmantech.com/assets/images/kent_w_airh_lg.jpg

Great post guys.

"Our watchword evermore shall be: The Maple Leaf Forever!"

|

|

|

DEAN C.

|

| posted on 9/2/06 at 09:42 PM |

|

|

Hi, the shaping hammer looks useful,a sort of cross between an english wheel and an old steam hammer(but smaller).

When you say an old air hammer I presume that you mean an air chisel?

Dean.......

Once I've finished a project why do I start another?

|

|

|

rabiddog

|

| posted on 10/2/06 at 12:54 AM |

|

|

If you email me i can probably dig out a few homemade and fabricated lathe plans in PDF for you most are available off the net just cant remeber where

i got them all from lol

All the Best

Craig

Mmmmmmmm......beer....aaaaarrrrrggggghhh

|

|

|

C10CoryM

|

| posted on 10/2/06 at 03:20 AM |

|

|

Crud, I lost what I had typed.

Dean, Yes an air chisel if you prefer.

Called air hammers here but 90% of the time you have a chisel bit of some sort in it anyhow.

The planishing hammer is used to smooth out rough marks and/or curve the sheet. Usually you beat out a peice roughly on a sandbag or similar then use

the air hammer to smooth out your hammer marks and fine tune. Can also be used similar to an english wheel. It is amazing how fast someone who knows

how to work a planishing hammer can beat out a peice  . .

You dont need a powerful hammer btw, its more about the hits per minute than the power.

Cheers.

"Our watchword evermore shall be: The Maple Leaf Forever!"

|

|

|