David Jenkins

|

| posted on 26/5/05 at 10:43 AM |

|

|

Finding the PCD?

I want to make a trim piece for the centre of my steering wheel. To do this I need to drill 6 holes to match the wheel's existing holes.

I don't want to drill through the wheel's holes, as the spokes are polished and likely to get scratched. I also need to be sure of the

centre's location as I'll be turning the piece in my lathe, and I cant get that from the wheel.

Is there a set technique for finding the PCD of a circle of holes? I have a digital vernier caliper, so I can take accurate measurements.

cheers,

David

|

|

|

|

|

DarrenW

|

| posted on 26/5/05 at 10:54 AM |

|

|

A Zeus book will give you the co-ordinates for hole centres for jig boring, i dont know if this will help.

What about making a template out of ply wood. Stg wheel on top, mark out the holes etc.

Can you measure to the outside of two opposite holes and then subtract one hole diameter? Same as measuring to the inside of two opposite holes and

adding one hole diameter assuming the holes are same diameter of course). This method will only work if the holes are dead opposite.

|

|

|

flak monkey

|

| posted on 26/5/05 at 11:14 AM |

|

|

Easy if you have a vernier....just do as Darren suggests...

Measure the distance from the outside of opposite holes. Then subtract the diameter of one of the holes, thats the PCD....

David

Sera

http://www.motosera.com

|

|

|

NS Dev

|

| posted on 26/5/05 at 11:44 AM |

|

|

The vernier calipers will easily tell you the pcd, but drilling the holes on that pcd is a touch trickier.

A dividing head or just a rotary table will make the job much easier. If you don't have one then i'd probably scribe a line at the pcd by

touching onto it with a sharp lathe tool while the hub is still in the lathe. Then after taking the hub out of the lathe, go round it with dividers

to get the hole centres.

I really really want a rotary table!!!!!!!!!!!!!!!!

|

|

|

locogeoff

|

| posted on 26/5/05 at 11:57 AM |

|

|

If you dont have opposing holes but they are equally spaced there is a mathematical method if you want I can explain but I've just lost it once

in my browser and cannae be arsed doing it again unless you actually need it!

|

|

|

David Jenkins

|

| posted on 26/5/05 at 12:15 PM |

|

|

Getting 6 equi-distant centre marks on the PCD is the easy bit!

Dot the centre point, and make a circle of PCD/2 using dividers. Dot a point on the circle, then use the dividers without changing the setting

to divide the circumference into 6.

With care this method is very accurate.

BTW: the 6 holes are equidistant round the PCD.

cheers,

David

|

|

|

NS Dev

|

| posted on 26/5/05 at 12:31 PM |

|

|

cheers for that, will have a divider play when I get home.

You're sorted then!

|

|

|

David Jenkins

|

| posted on 26/5/05 at 12:41 PM |

|

|

Reckon so...

...mind you, playing with a dividing head/rotary table is SO much more fun than a pair of boring old dividers!

David

|

|

|

locogeoff

|

| posted on 26/5/05 at 12:52 PM |

|

|

An ammendment to Darrens suggestion with your set up is to zero the digital verniers at the hole diameter then just measure the outside distance

between two opposing holes.

|

|

|

NS Dev

|

| posted on 26/5/05 at 01:02 PM |

|

|

quote:

Originally posted by David Jenkins

Reckon so...

...mind you, playing with a dividing head/rotary table is SO much more fun than a pair of boring old dividers!

David

Yep!! Still need/want one!

Do you know of a quick engineers tip for getting 4 equidistant holes on a PCD?? I need to make a flange to mount a wheel in my lathe to machine the

rim and I have just binned the hub I was going to use as a drilling jig!

|

|

|

mad4x4

|

| posted on 26/5/05 at 03:26 PM |

|

|

As said above this infromation is in a ZEUS BOOK

Scot's do it better in Kilts.

MK INDY's Don't Self Centre Regardless of MK Setting !

|

|

|

NS Dev

|

| posted on 26/5/05 at 04:41 PM |

|

|

ahhh, mybe so but I don't have one!

( I know I should but I don't!)

|

|

|

Rorty

|

| posted on 27/5/05 at 05:55 AM |

|

|

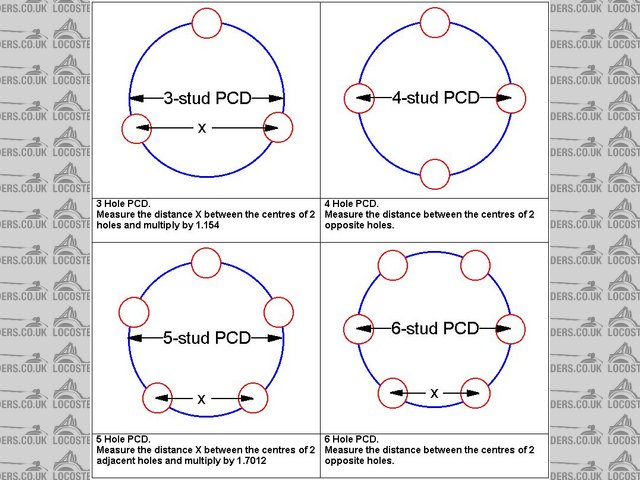

I found this, which saves me looking it up in some table or other:

Rescued attachment PCD_01.jpg

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

DarrenW

|

| posted on 27/5/05 at 09:11 AM |

|

|

quote:

Originally posted by mad4x4

As said above this infromation is in a ZEUS BOOK

4 equidistant holes are not in the Zeus book (or at least not in mine - 1970 - before i was born (just!)). They also quote them as dimensions for jig

boring which is only suitable if you have an accurate X-Y table. Otherwise it is down to accurate marking out from first principles, careful centre

punching and possibly going up a drill size for clearance holes just in case. If they are tapped holes you may need to open up the clearance holes on

the mating piece.

Using a centre drill will help alignment before drilling.

|

|

|

NS Dev

|

| posted on 27/5/05 at 09:55 AM |

|

|

That's the conclusion that I had come to as well!

I'm looking on ebay for a rotary table now!

|

|

|