Furyous

|

| posted on 13/7/12 at 09:58 AM |

|

|

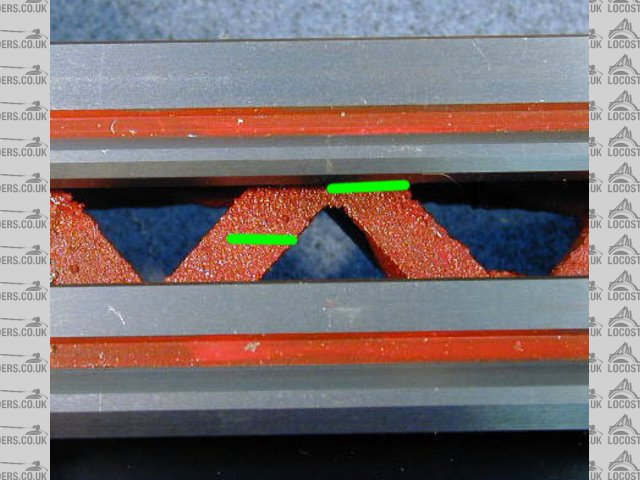

Hairline Cracks on a Lathe Bed

I've just bought a new lathe and after going through a lot of hassle with getting it upstairs at work, I found that there are a couple of

hairline cracks in the casting of the bed. One of them goes half way through a diagonal cross bracing and the other one seems to go all the way

through another point where the cross braces join the sides.

Are they likely to be a problem in the short and long term?

This isn't my photo but it shows what I mean a bit better.

Description

|

|

|

|

|

liam.mccaffrey

|

| posted on 13/7/12 at 10:15 AM |

|

|

if they are visible then are probably quite bad and I would asking for a refund/replacement if the lathe is new. Also if you have visible cracks its

quite likely you will have non visible too.

You might find that the lathe will do great work and remain accurate. But as with all cracks they will only get worse and it might be too late to do

anything about it. Worse case scenario is your lathe bed will snap in half when you're taking a heavy cut. Depending on what type of iron it

could be very brittle.

Part of my day job is testing weldments and castings for crack using magnetic particle methods.

Build Blog

Build Photo Album

|

|

|

HowardB

|

| posted on 13/7/12 at 10:16 AM |

|

|

how big is it? the lathe that is, and do you feel that you might be working it near it's limits either for tolerance or load?

If the answer is yes to either of those then some sort of fix might be advisable.

Howard

Fisher Fury was 2000 Zetec - now a 1600 (it Lives again  and goes zoom) and goes zoom)

|

|

|

Furyous

|

| posted on 13/7/12 at 10:29 AM |

|

|

Thanks for the replies. I think I knew what the answer was going to be but wanted another one.

It's 500mm between centres and it will pretty much only be cutting nylon and aluminium, but there will probably be steel at some point.

It was such a pain getting it upstairs. It's too heavy for two people to carry and the stairs aren't big enough for three or four people.

We had to borrow the neighbour's forklift to lift it over a balcony rail into the tooling area. I can't do anything about it until Monday.

|

|

|

TAZZMAXX

|

| posted on 13/7/12 at 10:50 AM |

|

|

Is there a chance you twisted it when lifting it upstairs? I'd be careful how I approached the supplier as they may state that it's been

lifted incorrectly. Just a thought. Maybe they were there already.

|

|

|

britishtrident

|

| posted on 13/7/12 at 11:27 AM |

|

|

When I was serving my apprenticeship one ship I was on had a large mechanical hacksaw , one day I had it working away sawing through a length of

steel angle when bang the cast iron bed of the machine broke clean across.

Crack that had been there since the bed had been cast had grown with every cycle of the saw until it reached l length where a few more strokes of

the saw resulted in instant brittle failure.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

perksy

|

| posted on 13/7/12 at 12:00 PM |

|

|

*If* this is under warranty i'd guess the first question from the supplier would be how has it been moved and where/how has it been installed

?

It needs sorting though as it could be an accident waiting to happen in the future, just thinking H & S now and the need for PPM inspections on

plant & equipment

|

|

|

Furyous

|

| posted on 17/7/12 at 05:29 AM |

|

|

The guys I bought it from brought another lathe into work for me as a replacement... only to find it was also cracked. Those were the only two they

had in stock so I went into their warehouse after work to see what else they had and they've sold me a bigger lathe for a little more.

I've ended up with a 675mm BC lathe for about £1100. They knocked $550 off the bigger one, instead of refunding me.  I've been

struggling to find a cheap lathe here in New Zealand. The cheapest new ones I've seen have been around £900 for a 300mm BC and about £600 for

something used, and often very tatty. The tooling we use on the printing machines includes some nylon "crowns" which grip onto bottle

necks. Apparently they cost $60-100 each and each machine needs at least 6. After a few of those, the lathe pretty much pays for itself. Once I

get to grips with things, I can't see them taking more than 10-15 minutes to knock up. Aside from the nylon, we also have aluminium mandrels,

cups, and housings to hold the bottles in place. We had a small cup made up not long ago with a very simple design. Basically a 4" cylinder with

a hole through the middle and a dished bowl in one end. It cost us $200. I own the lathe myself so I'll be taking it with me if I ever leave. I've been

struggling to find a cheap lathe here in New Zealand. The cheapest new ones I've seen have been around £900 for a 300mm BC and about £600 for

something used, and often very tatty. The tooling we use on the printing machines includes some nylon "crowns" which grip onto bottle

necks. Apparently they cost $60-100 each and each machine needs at least 6. After a few of those, the lathe pretty much pays for itself. Once I

get to grips with things, I can't see them taking more than 10-15 minutes to knock up. Aside from the nylon, we also have aluminium mandrels,

cups, and housings to hold the bottles in place. We had a small cup made up not long ago with a very simple design. Basically a 4" cylinder with

a hole through the middle and a dished bowl in one end. It cost us $200. I own the lathe myself so I'll be taking it with me if I ever leave.

They'll be delivering the bigger one tomorrow. It's a shame I don't have it now because things are a bit quiet at work.

|

|

|

40inches

|

| posted on 17/7/12 at 07:36 AM |

|

|

"I've been struggling to find a cheap lathe here in New Zealand"

That's one hell of a commute from Reading

|

|

|

Furyous

|

| posted on 17/7/12 at 07:48 AM |

|

|

quote:

Originally posted by 40inches

"I've been struggling to find a cheap lathe here in New Zealand"

That's one hell of a commute from Reading

It wouldn't be so bad if I had my car here.  It's not easy swapping an engine from 12,000 miles away. It's not easy swapping an engine from 12,000 miles away.

|

|

|