givemethebighammer

|

| posted on 20/6/04 at 08:11 PM |

|

|

Water pipe - stopping the hoses coming off

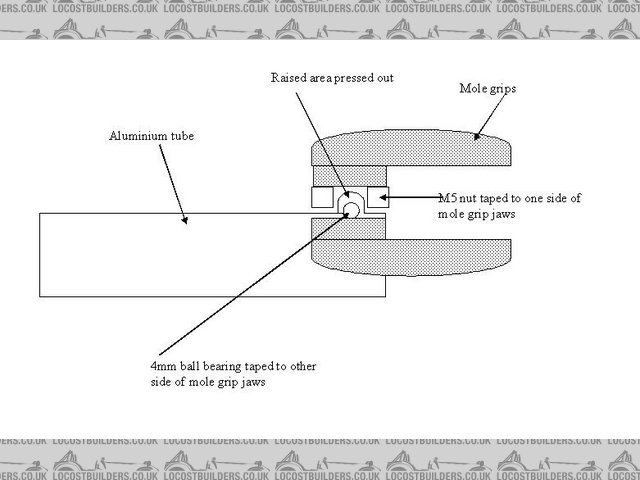

I have used aluminium tube to connect some of my Zetec plumbing to my Micra radiator together. I thought about how to produce a "single

flare" on the end of the tube to stop the pipe coming off under pressure. for a while and went through the various options. Some people here have

TIG welded blobs around the tube end to give something for the jubilee clip "butt", against. Others have used copper pipe and soldered a

compression ring on the end for the same reason.

So here is my version

I used 25mm OD aluminium pipe with a 1.2mm thick wall.

You need:

1. 1 x 4mm ball bearing (used in headset of mountain bike)

2. 1 x m5 nut

3. 1 x pair of mole grips

4. electrical tape

a. Use the electrical tape to attach the ball bearing to one side of the mole grip jaws.

b. attach the M5 nut to the other jaw with electical tape such that when the grips are closed the ball bearing sits inside the M5 nut.

Now get the aluminium tube (sure this would work on copper to), position the jaw of the grips with the ball bearing on so that the ball bearing

contacts the inside of the tube about 3mm from its end. Close the grips and the ball bearing will "press" a neat raised area on the outside

of the tube. Now do as many more as you feel you need (I did 4 per tube end.

Diagram should explain this..

[Edited on 20/6/04 by givemethebighammer]

Rescued attachment pipe retainer.JPG

|

|

|

|

|

Dave Ashurst

|

| posted on 20/6/04 at 08:50 PM |

|

|

Clever boy!

|

|

|

JoelP

|

| posted on 20/6/04 at 09:22 PM |

|

|

good idea GMTBH! on my copper tube i just welded blobs on. Whacked them with the file to make sure they were well stuck. On the aluminium ones a mate

put grooves with a lathe.

alls well as ends well i guess!

|

|

|

blueshift

|

| posted on 20/6/04 at 11:16 PM |

|

|

cool. someone else, I forget who, mutilated a pair of mole grips into a beading tool that could press a bead into copper pipe.. (for the sake of

completeness in case anyone's looking for more ideas)

|

|

|

robinbastd

|

| posted on 20/6/04 at 11:27 PM |

|

|

IIRC it was Steve Graber.

Only a dead fish swims with the tide.

http://smuttygifts.com/

|

|

|

britishtrident

|

| posted on 21/6/04 at 07:56 AM |

|

|

Never had a problem with hoses blowing off on any racer I built and I have used copper, steel, aluminium and even plastic for coolant pipes. -- if

hoses are blowing off somethings wrong, rad pressure cap or engine mount or the clip is just slack.

What is important is to get a nice rounded edge on the pipe to stop it cutting the hose.

|

|

|

givemethebighammer

|

| posted on 21/6/04 at 10:38 AM |

|

|

quote:

Originally posted by britishtrident

Never had a problem with hoses blowing off on any racer I built and I have used copper, steel, aluminium and even plastic for coolant pipes. -- if

hoses are blowing off somethings wrong, rad pressure cap or engine mount or the clip is just slack.

Never had a hose blow off either but no harm in belt and braces. Manufacturers put a "lip" on their water fittings so must be a reason for

it.

|

|

|

givemethebighammer

|

| posted on 21/6/04 at 10:46 AM |

|

|

Steve's idea here:

http://www.locostbuilders.co.uk/viewthread.php?tid=9080

|

|

|