02GF74

|

| posted on 10/9/10 at 06:55 AM |

|

|

OT (MTB) stopping shock end from moving, not what you think...

I want to replace rear shock on a mountain bike that has non-standard shock mounting.

One end has eyelet and other has internally thread rod.

The non-eyelet end bolts to rear triangle and does not move relative to the R.T.

Looking to use something like this:

which as eyelets at both ends so fishing for idea on making mount to stop movement.

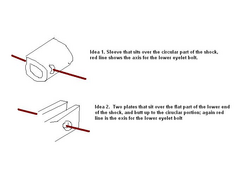

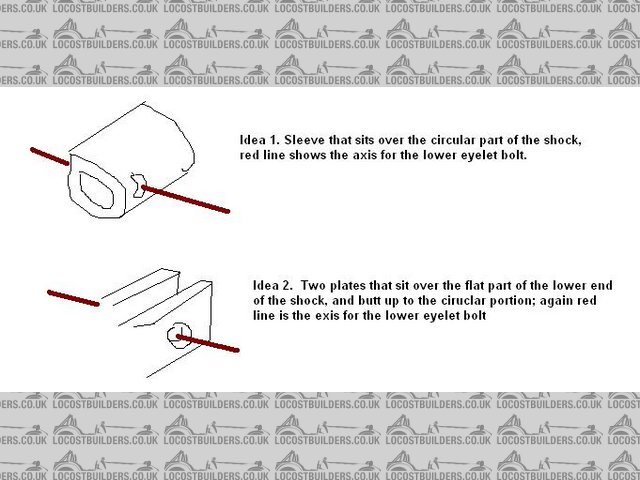

current thinking is a cylinder into whcih the lower end slides but not so much as to restrict travel or else two plates that butt up to the lower

stepped part..... hmmm, easier with a picture but not attchments in this section.

it's for this:

proflex xp8

(yes, I know there is no air in the tyres, hence the need for suspension  ) )

[Edited on 10/9/10 by 02GF74]

|

|

|

|

|

Staple balls

|

| posted on 10/9/10 at 07:02 AM |

|

|

know what the bike is?

Personally I wouldn't wee about trying to get something so non standard (and effing expensive) to fit, there's a good chance you'll

knacker the seals, and on an air shock, that leaves you with a very expensive, and useless paperweight.

|

|

|

balidey

|

| posted on 10/9/10 at 07:03 AM |

|

|

What you need to do is make a paper template of the bracket you need. Then make one in thin steel. Then another in ally. Then another in thicker

ally.

Then buy one

Dutch bears have terrible skin due to their clogged paws

|

|

|

02GF74

|

| posted on 10/9/10 at 07:05 AM |

|

|

this is wot I mean.

shock mount

shock is ebay 20 quid spesh so not end of world if it buggers up.

to get proper shock for the frame requires sending $298.00 to USA

|

|

|

02GF74

|

| posted on 10/9/10 at 07:06 AM |

|

|

quote:

Originally posted by balidey

What you need to do is make a paper template of the bracket you need. Then make one in thin steel. Then another in ally. Then another in thicker

ally.

Then buy one

|

|

|

02GF74

|

| posted on 10/9/10 at 07:25 AM |

|

|

quote:

Originally posted by Staple balls

Personally I wouldn't wee about trying to get something so non standard (and effing expensive) to fit, .

but that is no different to fitting a bike engine to a car? 'swhat we do on here

(and most of those end up as expensive paperwieghts too  ) )

|

|

|

SeaBass

|

| posted on 10/9/10 at 07:29 AM |

|

|

quote:

Originally posted by balidey

What you need to do is make a paper template of the bracket you need. Then make one in thin steel. Then another in ally. Then another in thicker

ally.

Then buy one

Nice

|

|

|

SeaBass

|

| posted on 10/9/10 at 07:33 AM |

|

|

The rear downlink and shock are effectively one long member. I presume the downlink screws into the base of the shock assembly to provide a solid

construction.

The loading on any "adapter" would be pretty large but it should be doable.

JC

|

|

|

balidey

|

| posted on 10/9/10 at 07:38 AM |

|

|

First, you need to pump up your tyres.

Second, do you need a new shock, could you not get the existing one overhauled? I would guess thats cheaper and easier than changing the mounts?

Thirdly, I don't think an adapter would be the best option, if I was doing it I would get a new shock, get it stripped, part off the eyelet and

get a thread welded onto the end, so basically making a new version of what you already have. But again probably no better than just servicing the

original item.

Dutch bears have terrible skin due to their clogged paws

|

|

|

balidey

|

| posted on 10/9/10 at 07:41 AM |

|

|

Or, the upper two arms going from the wheel to the shock. Are these bolted onto the lower wishbone? If they are then maybe you can remove these and

make a new pair but with the correct plates at the top to accept the eyelet?

Dutch bears have terrible skin due to their clogged paws

|

|

|

Staple balls

|

| posted on 10/9/10 at 08:01 AM |

|

|

oh wow, that things a bloody relic.

Are those '97 marzocchi Z1s?  (though, the Girvin Cross-Links looked so much more awesome) (though, the Girvin Cross-Links looked so much more awesome)

Honestly, I'd just pull the back end apart, lube what you can up with decent fork grease (as it doesn't eat seals) don't dismantle

the shock, it's not realistically serviceable.

If it squelches, the seals are gone in the valving, so the damping will suck, but it should still work.

|

|

|

3GEComponents

|

| posted on 10/9/10 at 09:55 AM |

|

|

Take a look here,

http://www.retrobike.co.uk/forum/viewtopic.php?t=87304&highlight=proflex

Now get on and measure those tabs,

Kind regards

John

|

|

|

02GF74

|

| posted on 10/9/10 at 10:02 AM |

|

|

^^^ ta - that is the exact conversion I am thinking of doing.

I didn't think mounting the lower eyelet at 90 degrees would be a great idea as it can still move albeit side-to-side - the rear end on those is

not the most rigid.

|

|

|

3GEComponents

|

| posted on 10/9/10 at 10:07 AM |

|

|

Does your back end have two holes on the drop out tab?

If so while you're measuring the Marzocchi tabs for me could you measure that one too?

That way i can do an adaptor for that aswell.

Kind regards

John

|

|

|

2cv

|

| posted on 10/9/10 at 12:52 PM |

|

|

I think your Idea 2 has a good chance of working. The two plates will butt up against the shoulder which will help it not to move and you can put a

rollpin through the shock eyelet into the bolt and another through the plate and into the bolt. That should stop any chance of movement. You can then

make a threaded fitting on the blocks to allow the existing lower rod to screw into. Job done, what could be simpler?

This is you task for today!

[Edited on 11/9/10 by 2cv]

|

|

|

nick205

|

| posted on 10/9/10 at 01:49 PM |

|

|

not seen a pro flex in years, they were earli in the full sus years. what happenef to the original elastomer srung multilink fronk forks?

|

|

|

Stott

|

| posted on 10/9/10 at 06:01 PM |

|

|

I've got a new pro flex, 768 enduro

Ok, ok, It's not really a pro-flex, but it's cool, and what else can you get with Pike's, a Monarch, reasonable groupset and

brakes for £680!!!

It's nice, see!:

Very big and boingy!!!!

[Edited on 10/9/10 by Stott]

|

|

|