StevieB

|

| posted on 11/3/10 at 08:35 PM |

|

|

How do you machine internal splines?

As above, just out of curiosity really, does anyone know how internal splines would be machined? For example, the aperture that drive shafts fit into

on sierra rear hubs.

|

|

|

|

|

Dingz

|

| posted on 11/3/10 at 08:40 PM |

|

|

Generally broached, long tapered profile tool pushed through component.

Phoned the local ramblers club today, but the bloke who answered just

went on and on.

|

|

|

blakep82

|

| posted on 11/3/10 at 08:41 PM |

|

|

do you mean a hole that doesn't go all the way through the metal?

i had my side gears re done to a 18 spline larger than original diameter hole. it was done by wire spark erosion (i think its called)

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

robocog

|

| posted on 11/3/10 at 08:44 PM |

|

|

http://www.youtube.com/watch?v=pab8MlMYNnc

...An example of broaching

Regards

Rob

|

|

|

v8kid

|

| posted on 11/3/10 at 08:57 PM |

|

|

Interesting, so it is a variation of a shaping machine.

I always thought that the broaching tool was the same size as the finished spline for some strange reason. (over active imagination I suppose!)

|

|

|

blakep82

|

| posted on 11/3/10 at 09:15 PM |

|

|

quote:

Originally posted by v8kid

Interesting, so it is a variation of a shaping machine.

I always thought that the broaching tool was the same size as the finished spline for some strange reason. (over active imagination I suppose!)

i guess it depends on the hole to be splined. a 30mm hole for a halfshaft in a side gear probably would be done in one go, but if its something like

that gear on the you tube video, finding the tool for one that make would be pretty hard i'd think.

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

Alan B

|

| posted on 11/3/10 at 09:26 PM |

|

|

quote:

Originally posted by v8kid

Interesting, so it is a variation of a shaping machine.

I always thought that the broaching tool was the same size as the finished spline for some strange reason. (over active imagination I suppose!)

Yes usually it is. Broaching is considered a relatively fast production process. Think of it more like milling but with a long straightened out cutter

that usually takes one pass only.

|

|

|

zilspeed

|

| posted on 11/3/10 at 09:29 PM |

|

|

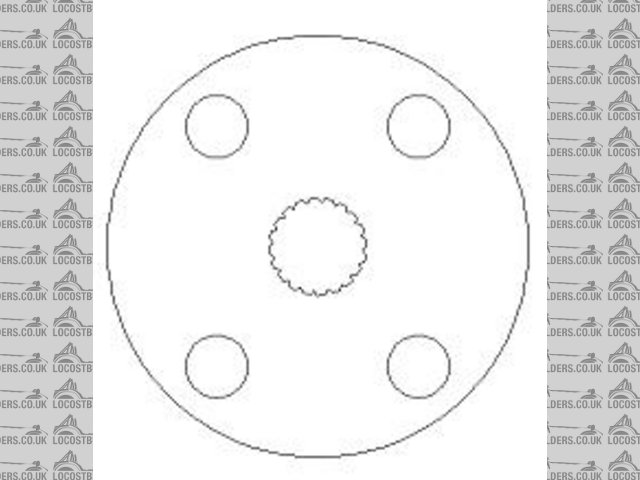

Andy of Waterjet fame made me an adapter with internal splines on it.

Drew it up on CAD, sent hime the file, he cut it with the waterjet. Job done.

Spline pattern fits the input shaft of an escort gearbox. Outside PCD fits a propshat flange.

Rescued attachment Adaptor.jpg

|

|

|

boggle

|

| posted on 11/3/10 at 09:44 PM |

|

|

spline cutting on a waterjet is not recommended over 10mm unless you have a dynamic head...jet wash leads to a tapered finish and a waterjet doesnt

run much more accurate than .2mm....

broaching, wire erosion and spark erosion are the only true accurate was of reproducing any form of involute spline....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

boggle

|

| posted on 11/3/10 at 09:46 PM |

|

|

quote:

Originally posted by Alan B

quote:

Originally posted by v8kid

Interesting, so it is a variation of a shaping machine.

I always thought that the broaching tool was the same size as the finished spline for some strange reason. (over active imagination I suppose!)

Yes usually it is. Broaching is considered a relatively fast production process. Think of it more like milling but with a long straightened out cutter

that usually takes one pass only.

unless broaching a keyway, then shims are used to to take cuts in stages untill at the required depth....

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

MakeEverything

|

| posted on 11/3/10 at 10:27 PM |

|

|

quote:

Originally posted by boggle

quote:

Originally posted by Alan B

quote:

Originally posted by v8kid

Interesting, so it is a variation of a shaping machine.

I always thought that the broaching tool was the same size as the finished spline for some strange reason. (over active imagination I suppose!)

Yes usually it is. Broaching is considered a relatively fast production process. Think of it more like milling but with a long straightened out cutter

that usually takes one pass only.

unless broaching a keyway, then shims are used to to take cuts in stages untill at the required depth....

Do you have a broaching machine?? - You know what the next question is!!!

Kindest Regards,

Richard.

...You can make it foolProof, but youll never make it Idiot Proof!...

|

|

|

Alan B

|

| posted on 11/3/10 at 10:29 PM |

|

|

quote:

Originally posted by boggle

quote:

Originally posted by Alan B

quote:

Originally posted by v8kid

Interesting, so it is a variation of a shaping machine.

I always thought that the broaching tool was the same size as the finished spline for some strange reason. (over active imagination I suppose!)

Yes usually it is. Broaching is considered a relatively fast production process. Think of it more like milling but with a long straightened out cutter

that usually takes one pass only.

unless broaching a keyway, then shims are used to to take cuts in stages untill at the required depth....

Yes true, and I should know, I've broached hundreds of keyways just as you say....I was really talking more about mass produced stuff.

|

|

|

boggle

|

| posted on 11/3/10 at 10:36 PM |

|

|

me too....builds up the biceps.....

rich.....

no i dont have a broaching machine and i hate getting involved with spline nomenclature.....without all the info to create an involute it will never

be right...

just because you are a character, doesnt mean you have character....

for all your bespoke parts, ali welding, waterjet, laser, folding, turning, milling, composite work, spraying, anodising and cad drawing....

u2u me for details

|

PLEASE NOTE: This user is a trader who has not signed up for the LocostBuilders registration scheme. If this post is advertising a commercial product or service, please report it by clicking here.

|

MakeEverything

|

| posted on 11/3/10 at 10:57 PM |

|

|

quote:

Originally posted by boggle

me too....builds up the biceps.....

rich.....

no i dont have a broaching machine and i hate getting involved with spline nomenclature.....without all the info to create an involute it will never

be right...

Just kidding!! Just kidding!!

Kindest Regards,

Richard.

...You can make it foolProof, but youll never make it Idiot Proof!...

|

|

|