alistairolsen

|

| posted on 11/6/09 at 01:10 PM |

|

|

Anyone tried polyeurathane in a lathe?

Anybody tried machining bushes down in a lathe?

what tools and how well did it work?

|

|

|

|

|

MikeCapon

|

| posted on 11/6/09 at 01:13 PM |

|

|

Hi. A lot of one off seals etc are machined from polyurethane. I believe the trick is to freeze the bar beforehand. Use a tip with a lot of rake as

for plastics. Never tried it though. Good luck!

|

|

|

tegwin

|

| posted on 11/6/09 at 01:17 PM |

|

|

I have seen people cut down bushes using a very sharp knife in a lathe....

.... Using liquid nitrogeon would be the easiest way of making it hard enough to machine properly

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

UncleFista

|

| posted on 11/6/09 at 01:27 PM |

|

|

quote:

Originally posted by alistairolsen

Anybody tried machining bushes down in a lathe?

Not in a lathe, no.

quote:

what tools and how well did it work?

I used a drill and a stanley knife

Worked great, I was only shortening them though, I didn't touch the circumference.

Description

Tony Bond / UncleFista

Love is like a snowmobile, speeding across the frozen tundra.

Which suddenly flips, pinning you underneath.

At night the ice-weasels come...

|

|

|

alistairolsen

|

| posted on 11/6/09 at 01:28 PM |

|

|

thats all i want to do, how did you hold them in the drill and whats withthe g clamp?

|

|

|

big_wasa

|

| posted on 11/6/09 at 01:42 PM |

|

|

Ive tried it in a lathe and I just chewed them up  even after freezing them. even after freezing them.

|

|

|

UncleFista

|

| posted on 11/6/09 at 01:46 PM |

|

|

quote:

Originally posted by alistairolsen

thats all i want to do, how did you hold them in the drill and whats withthe g clamp?

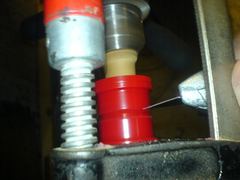

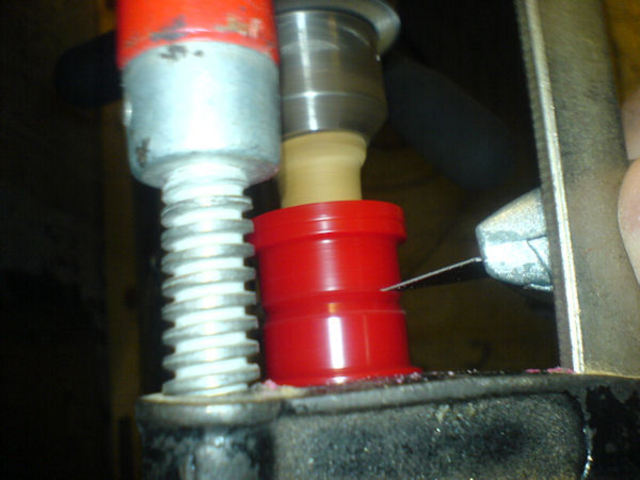

I just held a piece of wooden dowel the correct diameter in the chuck and slid the bush over it.

The clamp is to steady the knife against

More pictures here

[Edited on 11/6/09 by UncleFista]

Tony Bond / UncleFista

Love is like a snowmobile, speeding across the frozen tundra.

Which suddenly flips, pinning you underneath.

At night the ice-weasels come...

|

|

|

alistairolsen

|

| posted on 11/6/09 at 01:54 PM |

|

|

pillar drill, dowel pushed thru bush, tight fit. G clamp around table to steady/lever knife against and a sharp stanley knife?

Looks like it worked well. Apparently the raldes bushes Ive been looking at are 46mm while the brackets I have are 44mm lol Just want to take 1mm off

the shoulders

|

|

|

smart51

|

| posted on 11/6/09 at 02:15 PM |

|

|

I know someone who tried. He said don't. It is too rubbery and will either deform under the tool or will rip uneven chunks off. It grinds

well, he says, and suggests a dremel if you think you can do it accurately enough.

|

|

|

andylancaster3000

|

| posted on 11/6/09 at 03:07 PM |

|

|

Yes, it's an a*se. Whatever the salesman tells you take it with a pinch of salt.

We gave up and sub-contracted it to my grandfather! He ended up spending 75% of the time making the tooling to hold the stuff for the various cuts. If

you can buy them to fit it might be worth the extra dough!

|

|

|

stevegough

|

| posted on 11/6/09 at 09:21 PM |

|

|

Yes, I trimmed all my bushes in a lathe at work - most of them cut very neatly, but the secret is in the shape and sharpness of the tool - I ragged

about 6 of the faces before I got it right - I did all 44 this way.

Make sure you put a crush tube in the centre to cut down on deforming the bush with the chuck.

I can see where the guys are coming from regarding freezing them, though - the stuff is a bit soft to work. Also - use cutting fluid.

Regardz, Steve.

Luego Locost C20XE.

Build start: October 6th 2008.

IVA passed Jan 28th 2011.

First drive Feb 10th 2011.

First show: Stoneleigh 1st/2nd May 2011.

'Used up' first engine may 3rd 2011!

Back on the road with 2nd engine may 24th

First PASA mad drive 26/7/11

Sold to Mike in Methyr Tydvil 19/03/14

|

|

|