02GF74

|

| posted on 19/4/09 at 07:41 PM |

|

|

may need a favour - to make a hollow bolt

I have an alternator pulley with 17 mm hole that I would to fit onto an alternator with what appears to be M14 spindle.

I am going to buy a M12 stud connector and attempt to turn it down (by filing in a drill press) as well as drill the hole and tap to M14 x 1.5.

This may not be successful, so if I fail, is there anyone out there with a lather that can do this?

Namely drill a 11 mm hole and turn the outeer down to 17 mm OD?

I will supply the stud connector (a very long hex nut) and can post the 11 mm drill if you do not have one.

Yes, I realise M12 thread will eat up a bit of the M14 1.5 mm thread but I'll risk that.

Plan would be to turn a piece of steel, 17 mm OD and with 11 mm hole.

Anyone able to do this? (II doubt such a thing exists)

|

|

|

|

|

big_wasa

|

| posted on 19/4/09 at 07:50 PM |

|

|

Just had a look at this tonight.

Is the pulley and shaft tappered ? it is on the denso alt' I looked at tonight.

|

|

|

coozer

|

| posted on 19/4/09 at 07:53 PM |

|

|

I may be able to do it... if I have an 11mm drill...

Steel or ali?

Send me a drawing and I'll have a go

How long Alex? 17mm OD X 11mm ID x ??mm long.

Plenty of steel stock here.

Steve

[Edited on 19/4/09 by coozer]

[Edited on 19/4/09 by coozer]

1972 V8 Jago

1980 Z750

|

|

|

big_wasa

|

| posted on 19/4/09 at 07:58 PM |

|

|

Are you planning to move the pulley out from the alt' as that would be a bad idea. imho

You would be better with a sleeve 11mm inner and 17mm outer.

|

|

|

02GF74

|

| posted on 19/4/09 at 08:34 PM |

|

|

quote:

Originally posted by big_wasa

Are you planning to move the pulley out from the alt' as that would be a bad idea. imho

You would be better with a sleeve 11mm inner and 17mm outer.

is is power grip puller to fit onto a nippon denso.

the spindle is 20 mm long made up as:

4 mm hex section - 12 mm threaded - 4 mm solid

the depthj of pulley is 18 mm.

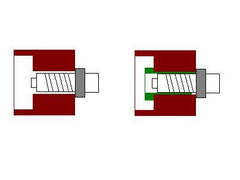

a diagram, not a good one, to show what is going on, the dark red is the pulley, white is spindle, grey is a spacerand green is the hollow

bolt.

Rescued attachment hollow bolt.JPG

|

|

|

big_wasa

|

| posted on 19/4/09 at 09:08 PM |

|

|

I still think the pulley and shaft are tappered.

|

|

|

02GF74

|

| posted on 20/4/09 at 07:19 AM |

|

|

quote:

Originally posted by big_wasa

I still think the pulley and shaft are tappered.

maybe but the pulley part that goes over the shaft is about 2 mm thick. The shaft has a non tapered section where the non tapered spacer sits, then

has M14 thread which does not appeared to be tapered as the nuts goes on fully both ways and the end bit has a non tapered hex section.

|

|

|

02GF74

|

| posted on 20/4/09 at 08:47 AM |

|

|

quote:

Originally posted by 02GF74

I am going to buy a M12 stud connector and attempt to turn it down (by filing in a drill press) as well as drill the hole and tap to M14 x 1.5.

eekk, ok, it was late when I posted this but that won'';t work.

M12 connector will have 17 mm AF so there will be no head to hold the pulley in place.

|

|

|

coozer

|

| posted on 20/4/09 at 09:55 AM |

|

|

u2u

1972 V8 Jago

1980 Z750

|

|

|

coozer

|

| posted on 20/4/09 at 09:03 PM |

|

|

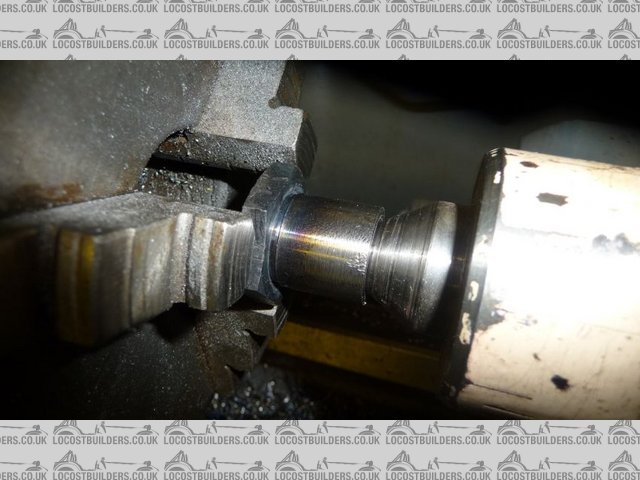

Nearly there, just need to turn the diameter down and get the correct length....

Rescued attachment M14 Threaded.jpg

1972 V8 Jago

1980 Z750

|

|

|

02GF74

|

| posted on 21/4/09 at 09:01 AM |

|

|

Brill - that looks awesome ...

|

|

|