02GF74

|

posted on 13/2/09 at 02:27 PM posted on 13/2/09 at 02:27 PM |

|

|

blind bolting

I have metal box to which I want to bolt something.

(numperrets to a bumper).

I cannot get access to the inside of the box.

How can I do this?

1. drill hole all the way though to insert socket head bolt from the back?

2. use internally spreading bolts, heavy duty versions of rivnuts but these are £ 3 a pop (I need 12) plus I don't think are flush.

other?

PU or welding is not an option.

|

|

|

|

|

Mr Whippy

|

| posted on 13/2/09 at 02:35 PM |

|

|

I'd have gone for the rivnuts tbh or large rivets. Why can't you weld it on?

Fame is when your old car is plastered all over the internet

|

|

|

02GF74

|

| posted on 13/2/09 at 02:40 PM |

|

|

oh, and there is another problem, see if you can spot it!

Rescued attachment aabb.JPG

|

|

|

chris_smith

|

| posted on 13/2/09 at 02:42 PM |

|

|

Rivnuts?

d'oh didnt read your post proper sorry

[Edited on 13/2/09 by chris_smith]

The secret of success is to know something nobody else knows."

|

|

|

02GF74

|

| posted on 13/2/09 at 02:46 PM |

|

|

quote:

Originally posted by Mr Whippy

I'd have gone for the rivnuts tbh or large rivets. Why can't you weld it on?

welding I would need to remove elecstrical gubbins, not a big deal but if I bend them, inbolting would be handy.

|

|

|

02GF74

|

| posted on 13/2/09 at 02:50 PM |

|

|

hmmm, just htought, maybe make a secret panel on the rear?

|

|

|

Mr Whippy

|

| posted on 13/2/09 at 02:59 PM |

|

|

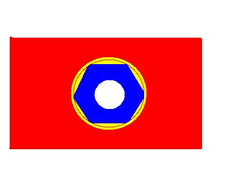

drill some holes in the bumper, then weld bolts over the holes on the outside. Then simply bolt the box on.

Or drill holes large enough for the nuts to fit through, hold them in place with a bolt while you weld them to the bumper, welding round the edge of

the nut. Like this (yellow is weld around the holes edge)

I know I'm a genius...

[Edited on 13/2/09 by Mr Whippy]

Rescued attachment 01bumper.JPG

Fame is when your old car is plastered all over the internet

|

|

|

britishtrident

|

| posted on 13/2/09 at 03:26 PM |

|

|

Normal way is to use a crush tube

Drill a hole through both sides.

Increase the size of the hole on one side so you can insert a crush tube cut to the correct length in and use large diameter thick washers on both

sides.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

02GF74

|

| posted on 13/2/09 at 03:29 PM |

|

|

^^^ yep - that is what I have on the tow points - I don't want them coming off!!

but bumper needs to allow some bending.

what you cannot see that there are 2 botls that go from the top - correct bumper is square C shape - and the holes align hence the crush tube will get

in the way.

|

|

|

NigeEss

|

| posted on 13/2/09 at 03:55 PM |

|

|

Assuming the bumper is 3mm box or greater can you not drill and tap ?

Time is an illusion. Lunchtime doubly so.................Douglas Adams.

|

|

|

Confused but excited.

|

| posted on 13/2/09 at 05:42 PM |

|

|

Or use chunky hex-head self tappers, like they use for steel roofing panels.

Tell them about the bent treacle edges!

|

|

|