zilspeed

|

| posted on 24/12/08 at 02:12 PM |

|

|

Exhaust Welding

Now that I've finally finished the engine mounts, I thought I would have a wee go at the exhaust before closing up the garage for a couple of

days for Christmas.

I really am in the early days of ability when it comes to welding, so it really was a case of suck it and see.

Using the Mig on minimum power with the straight CO2 I figured I might as well give it a go.

Now, please bear in mind that I have dressed this weld, but that doesn't matter a jot to me. As long as it's sound.

Really pleased with the way it turned out and am looking forward to getting a day in again and getting the job done.

This has been one of those jobs which has been hanging over me for months now - it's so pleasing to see that it just works. Seeing as I'm on

a budget as tight as a coat of p0aint, this is major good news. Probably quite trivial to someone that knows how to do this kind of stuff, but not

me.

Wee pic. One unifinished stub still with the slots in it from when I thought that sleeving the exhaust might be the way to go. Next to that, the

welded section, dressed ready for coating.

[Edited on 24/12/08 by zilspeed]

Rescued attachment cropped IM000805.JPG

|

|

|

|

|

SeaBass

|

| posted on 24/12/08 at 04:25 PM |

|

|

Looks super duper... Your skills are far better than you ever let on...

|

|

|

blakep82

|

| posted on 24/12/08 at 04:31 PM |

|

|

is the top one the one thats been welded?! looks great! looks like a single piece of metal sanded down a bit

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

dhutch

|

| posted on 24/12/08 at 05:01 PM |

|

|

Ive been loking at my exhast, seams to be a pin hole on one of the 4-2 joints showing through on the exhast wrap. Hesitent to have a go myself as it

might just get worse. But your work looks good to me only way to test it is to put it into service.

Daniel

|

|

|

zilspeed

|

| posted on 24/12/08 at 05:31 PM |

|

|

quote:

Originally posted by blakep82

is the top one the one thats been welded?! looks great! looks like a single piece of metal sanded down a bit

Cheers James, you can have a good close look next time you see it up close.

Blake

Yes, the top one has been welded and that is exactly the look I was going for, one piece which has been sanded.

Dhutch try this video for how to fill a hole

http://uk.youtube.com/watch?v=FTE9myzbuio&feature=channel

I made the fit as good as possible and where it had a slightly wider fit (like 1mm gap compared to 0.1mm at the good bits) I worked the weld across

from side to side along the front edge of the weld pool until I got back to the good fit again.

Believe this if you will, but it was watching programmes like American Chopper where all of their exhausts are cut and weld followed by polish that

convinced me I could go down this route.

Still to come, Zils guide to cutting a pre formed bend to maintain a constant radius and how to choose where to cut.

Oh, and have a Cool Yule everyone

|

|

|

jacko

|

| posted on 24/12/08 at 09:39 PM |

|

|

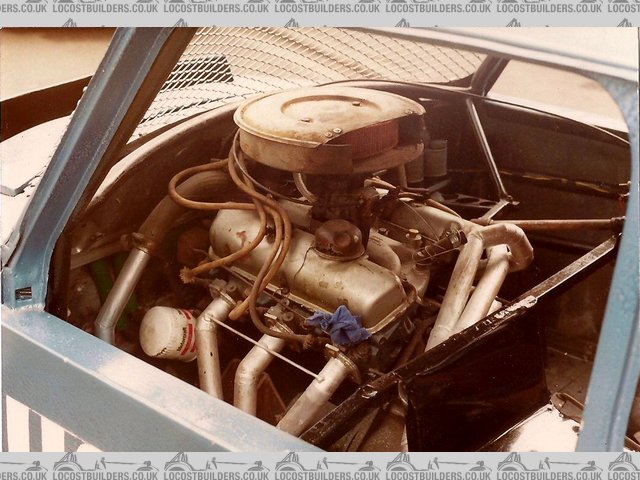

Who mentioned welding exhausts i made these about 30 years ago

Super Mini Engine

Jacko

|

|

|