andrew-theasby

|

| posted on 6/12/08 at 07:19 PM |

|

|

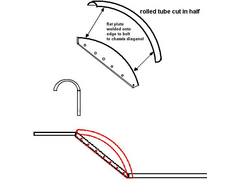

How to bend a C section in stainless

Hi, im after making some stainless "sill protectors" i suppose thyre called. I know how i want them to end up, but dont really know how to

make them locost style. Trouble is the tub at the side of the seats has no metalwork supporting it, and its the most tempting bit to help you out of

the car, so i was thinking of using some 2mm stainless to sit on top and be bolted to the chassis diaganol lower down so you can use it to get out.

Hopefully the diagrams will explain but i was thinking of using some tube ive got but would need bending, then cutting it in half and welding a flat

bar on one side, but im not sure i have enough tubing, is it possible to cut it in half first then curve it? Also i dont have a tube roller, is there

another way or do i need to approach a local company? The straight runs shouldnt be a problem. Any advice appreciated, Thanks.

Rescued attachment sill protectors2.JPG

|

|

|

|

|

andrew-theasby

|

| posted on 6/12/08 at 07:22 PM |

|

|

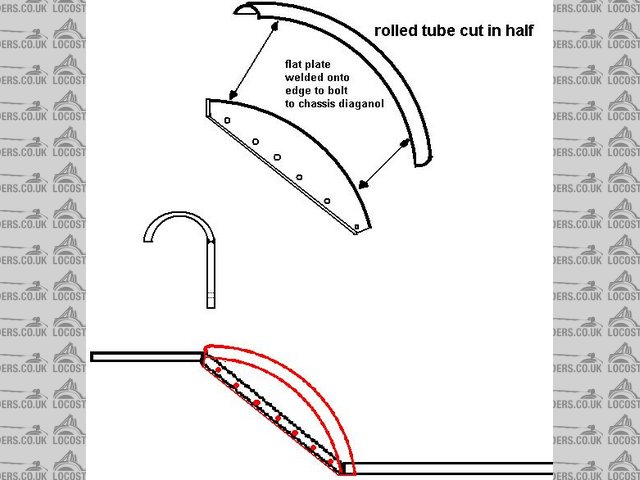

Rescued attachment sill protectors3.JPG

|

|

|

jacko

|

| posted on 6/12/08 at 09:25 PM |

|

|

Hi Andrew how are you keeping ?

The way i made my trims is

i made straight lengths of channel out of alloy 14g then put flat strips of alloy in the channel to fill it i then put it though the rollers at work i

hope that makes sense

Graham

MK fiber glass seats

|

|

|

jacko

|

| posted on 6/12/08 at 10:06 PM |

|

|

Andrew i have just had a idea how about a push bike mudguard cut to length

Graham

|

|

|

andrew-theasby

|

| posted on 6/12/08 at 10:21 PM |

|

|

Hi graham, im good thanks, cold, but well! I like your thinking, but i want it to be strong enough to put your weight on it, dont know if the mk is

the same but theres nothing under the fibreglass there on mine, which is why i wanted to use this nice bit of 2mm that i have. Also, it is round tube

in that area, but im just trying to think whether a flat channel like yours would cover it fully.

|

|

|

Simon

|

| posted on 6/12/08 at 10:28 PM |

|

|

I made mine from 1" angle iron. I cut "v's" into the side and bent the uncut side to the right profile. Welded up the

v's and ground flat. Where there were slight kinks in the flat bit (bit the you see on top, I ran it over the linnisher to finish. the sheeted

the gap per your pic.

See here for pic of mine in situ:

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=10000059.jpg

ATB

Simon

[Edited on 6/12/08 by Simon]

|

|

|

jacko

|

| posted on 6/12/08 at 10:30 PM |

|

|

Glad your ok have a good xmass

i see what you mean about the trim

never mind just a thought

Graham

|

|

|

andrew-theasby

|

| posted on 6/12/08 at 10:38 PM |

|

|

Hmmm, was just thinking along them lines myself, would that work with round tube(cut in half) do you think? Bet it would take forever to polish up tho

|

|

|

trextr7monkey

|

| posted on 7/12/08 at 09:59 AM |

|

|

Hi Andrew, It might be worth making from thick ABS - it would be strong enough and easier to work with than stainless- I have some suitable stuff

which is about 6mm thick in a nice shade of grey and by some strange coincidence I will be having a pub meal in the White Swan at Deighton on A19

next Saturday betwen 4pm and 6 ish so you could pick it up gratis then if you want to give it a go

atb

Mike

http://www.flickr.com/photos/14016102@N00/ (cut and paste this dodgey link)

Our most recent pics are here:

http://s129.photobucket.com/albums/p211/trextr7monkey/

|

|

|