Dangle_kt

|

| posted on 24/11/08 at 01:04 PM |

|

|

How to determine pitch on bolts/nuts.

Hi,

Is there an easy way of measuring the pitch on a bolt? I have just bought £10 worth of useless bolts as the pitch isn't fine enough!

The bolts are for the bolts securing my suspension on the rear end, and seems to require 19mm nyloc nuts, but the pitch is really fine.

Don't want even more useless nuts and bolts, and I dont have time to go to a local supplier, I need to buy online as I work 8.30 - 5 (but

usually way after 6pm) and everywhere is closed.

Thanks

|

|

|

|

|

mistergrumpy

|

| posted on 24/11/08 at 01:07 PM |

|

|

You can get a pitch gauge. Mine came free with some cheap taps and dies. That or measure them with a vernier caliper. Peak to peak or trough to

trough. After a while you can just look at the things and see what they are.

|

|

|

DavidM

|

| posted on 24/11/08 at 01:13 PM |

|

|

First you need to establish imperial or metric by measuring the diameter.

If metric, then measure ten threads peak to peak and divide by ten for the pitch. ie. M12 x 1.5

If imperial then count how many threads per measured inch ie. 1/2" 12tpi

HTH

David

[Edited on 24/11/08 by DavidM]

Proportion is Everything

|

|

|

Dangle_kt

|

| posted on 24/11/08 at 01:17 PM |

|

|

pitch gauge it is! My calipers are really poor quality, so I'll just be asking for trouble!

Thanks guys, I'll get on ebay.

|

|

|

02GF74

|

| posted on 24/11/08 at 01:33 PM |

|

|

what has happened to the locost spirit! pitch gauges indeed.

take a piece of paper and press it against the bolt - helps if bolt is a bit dirty/greasy. This leaves an imprint of the threads and then by using a

ruler, measure distance between 11 lines (10 full pitch cycles, ivide by ten and there you have. Esire then using vernier calipers.

pitch guage indeed

|

|

|

Dangle_kt

|

| posted on 24/11/08 at 02:03 PM |

|

|

Easy tibbles!

My calipers were only a pound and so I'll spend the few quid I saved on some cheap £2.00 pitch gauges.

I think I can stump up the £2.00, and it will save me spending £10 on DUFF PARTS!

GREEZY bolts indeed!

|

|

|

britishtrident

|

| posted on 24/11/08 at 03:46 PM |

|

|

If you are building a car you will need a basic set of metric tap and dies if only to clean up the threads -- loads of sets on ebay that come with

pitch gauges ----- very low cost item.

Also usually best to order nuts and bolts together. Most local nut & bolt suppliers are too big to care so most kit and classic car people on

here use Namrick http://www.namrick.co.uk/ at some point.

|

|

|

tomblyth

|

| posted on 24/11/08 at 04:38 PM |

|

|

number on bolt head eg 8.8 means metric lines on bolt head means inperial!

|

|

|

Dangle_kt

|

| posted on 24/11/08 at 05:25 PM |

|

|

I have a metric tap and die set, but only for the wide pitch stuff and only for metric.

Its only on the more specilist bolts that I am unsure on.

Thanks for all the tips thought guys - they all get filled away for future emergencies!

|

|

|

rusty nuts

|

| posted on 24/11/08 at 07:13 PM |

|

|

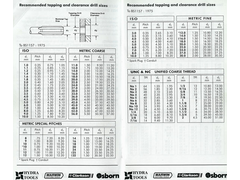

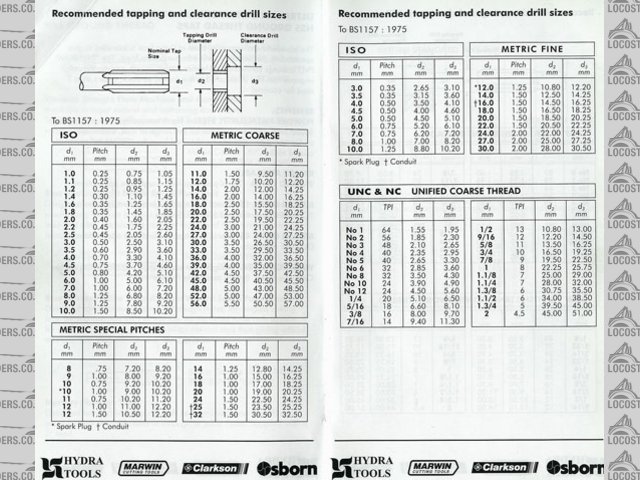

A Zuess chart is a good investment as well , gives loads of info on pitch,diameter and hole sizes for tapping amongst other things. Any good

engineering suppliers should have them at less than a fiver.

|

|

|

maartenromijn

|

| posted on 24/11/08 at 08:22 PM |

|

|

quote:

pitch gauge it is! My calipers are really poor quality, so I'll just be asking for trouble!

How can you live with poor quality calipers??

[Edited on 24/11/08 by maartenromijn]

BLOG: http://thunderroad-super7.blogspot.com/

|

|

|

907

|

| posted on 24/11/08 at 08:37 PM |

|

|

Hi.

A useful dodge is to use a standard metric coarse bolt as a thread gauge.

By holding a smaller coarse bolt against the larger metric fine thread you can see if it is the same pitch.

e.g.

6mm coarse is 1mm pitch.

It will be the same pitch as a brake pipe thread. (10 x 1)

10mm coarse is 1.5 pitch.

It will mesh with 18 x 1.5

Below is a page from my Hydra Tools book.

I think if you right click on it you can download it.

HTH

Paul G

Rescued attachment thread-pitch-3-s.jpg

|

|

|

MautoK

|

| posted on 31/12/08 at 07:03 PM |

|

|

quote:

Originally posted by tomblyth

number on bolt head eg 8.8 means metric lines on bolt head means inperial!

The 8.8 and 12.9 marking refer to tensile strength but not sure of the precise significance - except bigger number=stronger.

He's whittling on a piece of wood. I got a feeling that when he stops whittling, something's gonna happen. (OUATITW/Cheyenne)

|

|

|

mistergrumpy

|

| posted on 31/12/08 at 07:13 PM |

|

|

I think what was meant to be said was that only metric uses the 8.8 or 12.9 systems whereas imperial uses the lines.

|

|

|

C10CoryM

|

| posted on 31/12/08 at 07:18 PM |

|

|

quote:

Originally posted by MautoK

The 8.8 and 12.9 marking refer to tensile strength but not sure of the precise significance - except bigger number=stronger.

Yes the numbers on the head indicate the tensile strength. 8.8 is about 800MPa, 12.9 is around 1200MPa.

But that is only a metric way of doing it so if you see numbers, it's a metric bolt

Imperial uses lines on top of the head. 3 lines = grade 5 bolt. 6lines = grade 8 etc.

If your bolts have no lines or numbers they are not acceptable to automotive use. Grade 5 is the minimum.

Cheers.

"Our watchword evermore shall be: The Maple Leaf Forever!"

|

|

|