907

|

| posted on 3/2/05 at 09:10 PM |

|

|

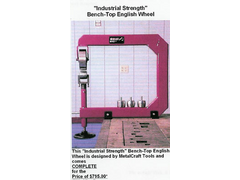

English Wheel

With a little bit of prompting from a mate,

I'm contemplating having a bash at making one of these.

Anyone ever used one ?

Aluminium wheel arches would be sooo nice.

With a bit of practice maybe even a nosecone ?

Paul G

Rescued attachment english wheel s.jpg

|

|

|

|

|

mangogrooveworkshop

|

posted on 3/2/05 at 09:49 PM posted on 3/2/05 at 09:49 PM |

|

|

So dam expensive!

http://www.eastwoodco.com/jump.jsp?itemType=CATEGORY&itemID=829

|

|

|

Mark Allanson

|

| posted on 3/2/05 at 10:11 PM |

|

|

For anyone with a decent welder and a lathe, it could be a locost proposition?

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

mark_UK

|

| posted on 3/2/05 at 10:13 PM |

|

|

Might get some ideas here: http://allshops.org/cgi-bin/community/cforums.cgi?forumid=109061855423990

and this one:

http://www.roddingroundtable.com/tech/articles/12ewheel.html

[Edited on 3/2/05 by mark_UK]

|

|

|

stevebubs

|

| posted on 3/2/05 at 10:23 PM |

|

|

Frost Used Section

|

|

|

Browser

|

| posted on 3/2/05 at 10:32 PM |

|

|

quote:

http://www.roddingroundtable.com/tech/articles/12ewheel.html

[Edited on 3/2/05 by mark_UK]

Had a look at that one and it looks great! I'll definitely HAVE to try and get the bits together for one and have a go. Always wanted one but

could never justify the expense, but I think I can stretch to a couple of bearings and can probably scrounge the frame metal from offcuts from local

fabricators.

[Edited on 3/2/05 by Browser]

|

|

|

mark_UK

|

| posted on 3/2/05 at 11:05 PM |

|

|

quote:

Originally posted by Browser

Had a look at that one and it looks great! I'll definitely HAVE to try and get the bits together for one and have a go........

[Edited on 3/2/05 by Browser]

At thetime I was looking about 6 months ago one guy had a site up showing you everything drawings sizes the lot.Unfortunately someone pointed out he

could make some money from it,needless to say the web site disappeared  Doesnt look too hard to "wing it" tho Doesnt look too hard to "wing it" tho

|

|

|

Rob Lane

|

| posted on 3/2/05 at 11:08 PM |

|

|

Eddy White was selling a bench mounted version on ebay not long ago for something around £150.

The larger ones fetch a lot of money.

Martin at MK made himself a freestanding one quite cheaply I believe.

|

|

|

timsta

|

| posted on 3/2/05 at 11:23 PM |

|

|

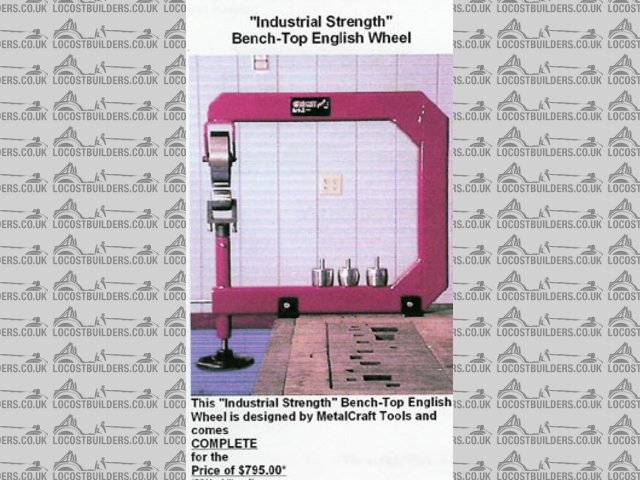

'ere you go: http://www.metalcrafttools.com/engwheel.html

You shouldn't need the plans, it all look simple enough.

Or, step by step: http://www.roddingroundtable.com/tech/articles/12ewheel.html

[Edited on 3/2/05 by timsta]

|

|

|

CairB

|

| posted on 3/2/05 at 11:25 PM |

|

|

I'm sure that some of the FEA designers amongst us could present a minimum metal, optimised solution made from left over 1" RHS, a bit of

hydraulic tubing, used wheel bearings, and a pair of wheels for the diy toolers to fabricate.

Then we can all hum those old favourites whilst we fabricate such as:

We'll meet again..

4 wheels on my waggon..(sorry that's american)

Cheers,

Colin

|

|

|

907

|

| posted on 4/2/05 at 12:37 AM |

|

|

Another one is:-

http://www.roddingroundtable.com/tech/articles/12ewheel.html

This shows how to make one, including the rollers, a "Ford axle bearing" and a "pillow block bearing".

I'd estimate £70 for the whole thing.

Paul G

|

|

|

Soul-tez

|

| posted on 4/2/05 at 03:39 AM |

|

|

There is a ton of metalshaping info here http://www.metalmeet.com/forum/index.php

|

|

|

Rorty

|

| posted on 4/2/05 at 05:49 AM |

|

|

I cant let this topic go by without posting this link.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

timf

|

| posted on 4/2/05 at 08:25 AM |

|

|

for those making the full sized ones.

and needing anvils etc

look here for a us vendor who exports and for a resonable price

|

|

|

David Jenkins

|

| posted on 4/2/05 at 08:42 AM |

|

|

You could also look here

The Tin Man

The frame doesn't look too hard to a man with your skills - but the hardened rolls are expensive!.

David

|

|

|

907

|

| posted on 4/2/05 at 08:28 PM |

|

|

Good replies chaps, but still want to find someone who has used one.

Anyone know where you can buy "casenite"? ( case hardening powder )

Paul G

|

|

|

David Jenkins

|

| posted on 4/2/05 at 09:12 PM |

|

|

Paul,

It's spelled with a 'K' - Kasenite or Kasenit - I know a few model engineering suppliers but they tend to sell small quantities

only. Blackgates Engineering is one - a Google will find them.

Otherwise it comes in big tins - £82 + VAT for 5kg is one I found!

David

|

|

|

gazza285

|

| posted on 4/2/05 at 10:04 PM |

|

|

You could take the anvils to your local engine refurb spot and ask then to nitride/tuffride them.

|

|

|

Rorty

|

| posted on 5/2/05 at 12:10 AM |

|

|

quote:

Originally posted by David Jenkins

Paul,

It's spelled with a 'K' - Kasenite or Kasenit - I know a few model engineering suppliers but they tend to sell small quantities

only. Blackgates Engineering is one - a Google will find them.

Otherwise it comes in big tins - £82 + VAT for 5kg is one I found!

David

In the good old days before proprietry case-hardening compounds, blacksmiths and toolmakers used various recipes to impart a higher carbon layer on

steel. Ground hooves and horn were favoured by my local blacksmith; he just plunged machine parts into a bucket of the powder. A friend in NI was a

turner and fitter for Goodyear and he preferred his secret mixture that contained sugar! It smelled like candyfloss when he used it. Basically,

anything that's friable and high in carbon will do the trick.

I made a really smart pair of large dividers and case-hardened them in the hoof and horn mix. I still have them to this day and they are perfect; no

perceivable wear or surface damage.

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|

907

|

| posted on 5/2/05 at 07:43 AM |

|

|

I like the idea of the sugar Rorty.

I assume that it would catch fire if a red hot lump of steel was dipped in it.

At a lower temp it would turn to toffee.

Ummm, maybe I'll try that.

Paul G

|

|

|

NS Dev

|

| posted on 5/2/05 at 11:28 AM |

|

|

907, if you have an oxy-acetylene torch and plenty of gas, just flame harden!

Get a rich flame going and play it over the part for a good while, then up the oxygen and blast it until dull red and quench.

|

|

|

907

|

| posted on 5/2/05 at 05:05 PM |

|

|

It makes me think of my college days.

" The Products of the Oxyacetylene Flame "

O, the good old days.

Paul G

|

|

|

907

|

| posted on 26/10/05 at 07:38 PM |

|

|

The day I start making the bodywork is looming, so I thought I'd better crack on with the "wheel".

It's cost me £48 so far, so a waste of money..... or a bargain?

I'll probably knacker loads of ally sheet,

then go and buy some fibreglass.

Paul G

Rescued attachment E-wheel-s.jpg

|

|

|

David Jenkins

|

| posted on 26/10/05 at 09:29 PM |

|

|

Um... isn't the bottom wheel supposed to adjustable up and down? The real e-wheels have a big wheel at the bottom to adjust the roller

spacing.

Or is that bit hidden somewhere?

David

|

|

|

Rorty

|

| posted on 26/10/05 at 09:47 PM |

|

|

Yes, the anvil has to be adjustable. Here's my set-up:

Rescued attachment e-wheel_02.gif

Cheers, Rorty.

"Faster than a speeding Pullet".

PLEASE DON'T U2U ME IF YOU WANT A QUICK RESPONSE. TRY EMAILING ME INSTEAD!

|

|

|