What is a Flat Drill

ditchlewis - 12/9/07 at 07:49 AM

I have to re drill the base of my starter motor. it is retained with a allen headed bolt that is flush with the face of the base.

the man at cambridge motorsport said i needed a flat head drill. what is one of these?

i know that i have to drill a hole for the bolt but then i have to ream out the base to get the bolt to sit flush with the face.

is a flat head drill bit one of these?

Ditch

Rescued attachment flat drill.JPG

Hurdsey - 12/9/07 at 07:58 AM

Nope thats a Flat Bit for wood.

I'm not an engineer but I think a flat head drill is designed to drill holes with a flat bottom instead of a bevelled bottom iyswim. I'm

sure a good Engineers merchants would stock them.

It may be reffered to as a Reamer but I'm not sure.

Mark Allanson - 12/9/07 at 07:59 AM

..or perhaps an end mill

designer - 12/9/07 at 08:00 AM

The drill you showed is for wood.

A flat drill the bloke is talking about is one used when the hole does not go through the piece being drilled and it leaves a flat bottom to the

hole.

Where are you drilling on the base? Are you just making another mounting hole?

JAG - 12/9/07 at 08:02 AM

It's not referred to as a Reamer.

But it is a drill designed to cut a flat bottomed hole.

Be very careful when using it - the shorter cutting edge (than a normal drill) means they need a lot of torque to drive them and can only cut

relatively slowly

Fred W B - 12/9/07 at 08:16 AM

Its called a spot face tool.

If you can't find one can you change to a bolt with a countersunk head, as a chamfer tool is easier to find?

Cheers

Fred W B

[Edited on 12/9/07 by Fred W B]

ditchlewis - 12/9/07 at 08:31 AM

many thanks lads

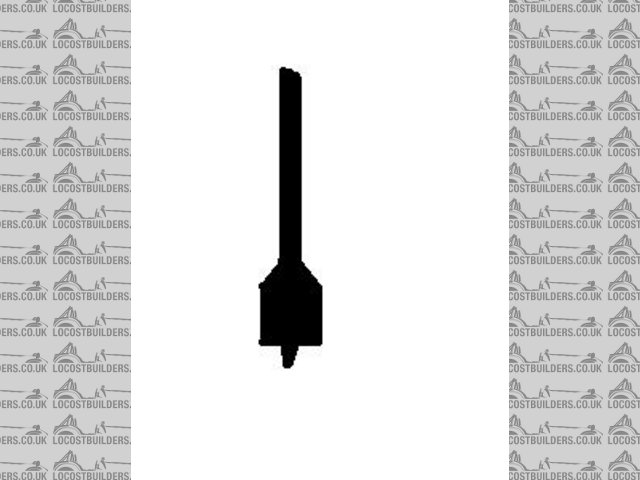

the alloy mounting plate on my starter motor needs moving round. the existing holes have a flat bottom to them to seat the bolt flat and flush to the

face.

Fred's idea sounds good.

the question i now have is in a high torque application is option A (see below) more likley to fail than the existing option?

ditch

[Edited on 12/9/07 by ditchlewis]

ditchlewis - 12/9/07 at 08:32 AM

here is the pick

Ditch

Rescued attachment options.JPG

02GF74 - 12/9/07 at 09:06 AM

quite possibly but not that you would ever achieve it.

basically, and I could be wrong, the weakest part of the bolt is the thinest part i.e. the threaded section - that would where it would fail so the

shape fo the bolt head does not matter.

Mr Rob - 12/9/07 at 10:11 AM

If you have a bench grinder you can grind a normal drill bit flat. Drill the hole first with a normal drill an then go in with your new ground bit....

job done.

ditchlewis - 12/9/07 at 11:08 AM

just remembered that i bought some bits very early on in my build that may do the job.

i will have to look and measure what i have.

i will have to drill a hole for the bolt first then i will have to use these bits (see below).

. these bits have a flat face on them.

. these bits have a flat face on them.

Ditch

Rescued attachment bit.JPG

iank - 12/9/07 at 12:04 PM

That looks like a lip and spur drill (flat with a spike) I think they are just for wood (also called a dowel bit IIRC).

tks - 12/9/07 at 12:45 PM

quote:

Originally posted by Mr Rob

If you have a bench grinder you can grind a normal drill bit flat. Drill the hole first with a normal drill an then go in with your new ground bit....

job done.

i wouold try this idea, because with a flat drill its not easy to pick the right place of drilling, saying that, when you cut down a normal drill, you

don't leave a cutting edge.

i would go for the countersunk screws.

timf - 12/9/07 at 01:07 PM

you need something like this

http://www.screwfix.com/search.do;jsessionid=A0P1YSBZSQFOYCSTHZPCFFI?_dyncharset=UTF-8&fh_search=counterbore

or from ebay

http://stores.ebay.co.uk/Mattools_CUTTING-TOOLS_Countersinks-Counterbores_W0QQcolZ4QQdirZ1QQfsubZ3277677QQftidZ2QQtZkm

looks like

[Edited on 12/9/07 by timf]

ditchlewis - 12/9/07 at 01:28 PM

iank

the above drill was for steel and was titanium, it went through steel like butter

.

.

problemis that i have used them all alot and they are probably blunt now

and they were about a ten to fifteen quid each.

and they were about a ten to fifteen quid each.

ditch

02GF74 - 12/9/07 at 01:43 PM

when I had to do something like this i.e. fltten out hte bottom of a blind drilled hole, I used end mills.

mmart do a set from 4 to 10 mm.

Alan B - 12/9/07 at 02:08 PM

As Timf shows the correct tool is called a counterbore......a spotface is essentially a shallow counterbore used on castings or rough surfacee to give

a true seating face.

They can be bought in sets with interchangeable pilots or individually.

907 - 12/9/07 at 04:02 PM

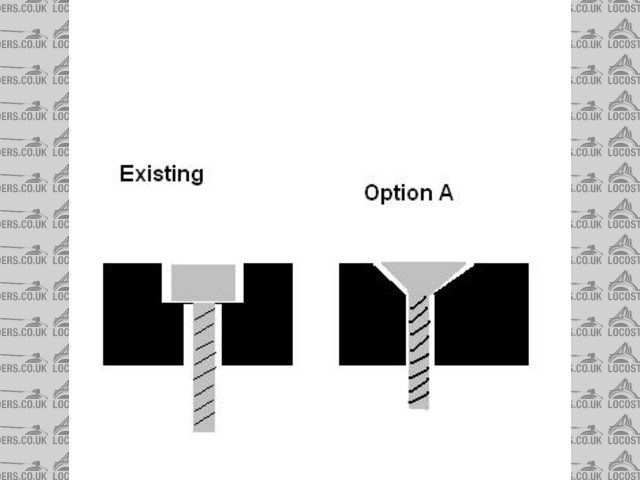

Mr Rob has the locost option.

In with a normal drill to below the surface, then take out the angle with a flat one.

A drill is a drill. How you just sharpen it depends on what you want to do.

Hth

Paul G

Rescued attachment drills-tx-s.jpg

NS Dev - 13/9/07 at 05:46 PM

as Mr Rob and 907 said, just grind a std drill bit flat at the end.

I have used this to do spot facing many times, as spot face cutters are very expensive!!

MikeRJ - 20/9/07 at 09:43 PM

quote:

Originally posted by iank

That looks like a lip and spur drill (flat with a spike) I think they are just for wood (also called a dowel bit IIRC).

But they do work on metal with a bit of modification! My spot weld cutter fell to pieces during a job some time back and I modified one of these wood

bits to make the spike shorter and it ripped through dozens spot welds with little problem. It was a reasonably quality drill bit though, not a

cheapy.

iank - 21/9/07 at 09:35 AM

Using them as a spot weld cutter would be fine I'd image, but they bind if you try and drill thick metal due to the cutting geometry.

http://en.wikipedia.org/wiki/Drill_bit

The one's I've got scream into wood with the lightest pressure, they actually seem to tunnel into the hole on their own.

Vindi_andy - 21/9/07 at 12:25 PM

when we had to use flat ended drills at college during my apprenticeship(many moons ago) we always had to drill the hole with a standard drill first

then just flatten the bottom of the hole with the flat drill

Part of the problem I experienced was as someone else said earlier about the centreing also if you dont have a pre drilled hole the bit has a tendecy

to wander