TIG Antifreeze

NS Dev - 27/10/06 at 07:27 AM

Probably a question for 907!

Can I use normal car antifreeze in my TIG?

I have read not because "car antifreeze contains chemicals to block leaks" which obviously would block the power lead connections.

I didn't think modern car antifreeze had anything like that in it though.

Just guessing that welder antifreeze will cost lots more than car stuff??

Need to sort it as its getting colder now!!!

907 - 28/10/06 at 07:46 AM

Hi Nat.

Never used anti freeze myself, but I would think that if you buy the cheap stuff

from a cut price shop it doesn't have additives in it.

At work we have a frost stat on the heating system set at +1 deg.

I made my own water cooler for the garage. A car heater matrix (£5), 8" house fan (£12.99),

and a pond fountain pump (£15) mounted in a little stainless tank I knocked up.

It beats paying £300 plus for the proper thing.

Because it's mounted on a shelf below the welder when I switch off it drains back to the tank,

so should it freeze it shouldn't hurt the welder.

I do use distilled water to cut down corrosion of the copper braid in the power lead.

Welder antifreeze is a lot more expensive, depending if it's a blend, or a single malt.

It does effect weld appearance though.

You could just buy a fan heater with a frost setting.

atb

Paul G

P.S.

Never use any mild steel fittings, not even plated ones, in the lines.

I think you get some sort of reaction between electricity, steel, and the copper braid.

[Edited on 28/10/06 by 907]

NS Dev - 31/10/06 at 09:44 AM

thanks paul.........bit worrying as my machine came with a pump that is cast iron! Its a retro fit slightly heath robinson jobbie but seems ok so

far............

I'll have a look and see what colour the water is when I drop it out tonight!!!!

Think I'll go for the car antifreeze and see what happens.

A s/h non-trigger torch and cable assy isn't megabucks anyway and mine is pretty tired!

The bit that surprises me with my machine is that the cooling pump is quite large (and noisy! ) but the water flow is only a trickle....is that

normal?

907 - 31/10/06 at 08:54 PM

Hi Nat

My home torch is one from the scrap bin at work.

We use 6m long leads and this one had a accident with a hot welding rod stub.

I've cut it down and remade the connections. Still 4m long, plenty for home use.

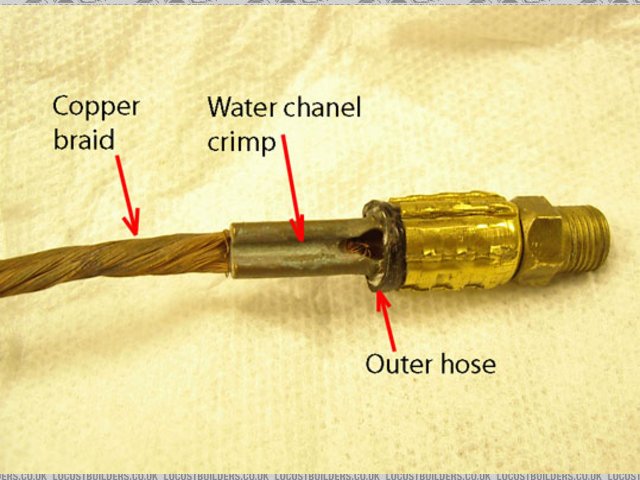

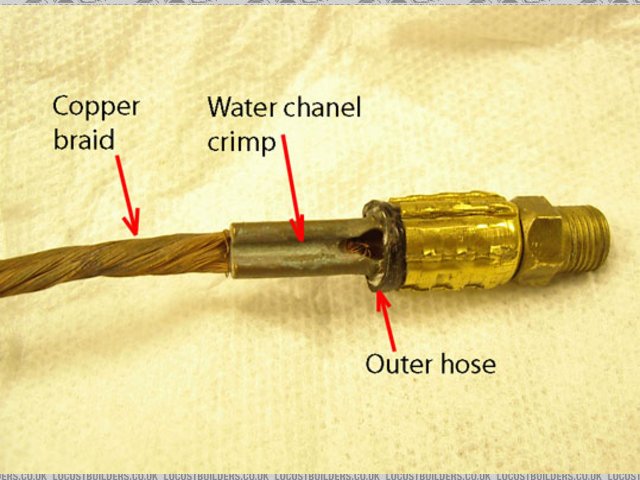

The copper braid can corrode and then it swells, restricting water flow.

A 300amp braid is 6mm, running in a 10mm i/d hose.

The braid is also a trap for any particles in the water, rust from a mild steel fitting for instance.

If your lead has been repaired then the water channel crimp may be, err, less than

perfect, (read, crunched in a vice) thus restricting flow.

The give away is the outer crimp replaced with a jubilee clip.

You could try a mains water flush the reverse way to the flow direction on the set.

You'll be surprised what comes out.

HTH

Paul G

Rescued attachment tig-con-s.jpg

NS Dev - 1/11/06 at 11:11 AM

lol that connection was snapped off on mine where the fellow that was selling it knocked it in his excitement while showing me the machine!!!

I remade it by drilling the copper tube out of the brass end, drilling a hole in the side of some copper pipe, crimping the braid into it, then press

fitting (with loctite) the copper tube into the drilled out end fitting.

A local welding supplies place quoted me £50 for a compete 200amp water cooled torch and lead assy while I was pondering how to mend it!

Did the water change and anti-freeze addition last night, the water flow is fine, if anything better!!

Only prob now (last night, not tried today) it keeps tripping the earth leakage trip in the house!!! Doh!!! I spilt some water round the pump motor

(though not on/in it) I'm hoping its just that creating some earth leakage or something, will try again when its fully dry!

907 - 1/11/06 at 08:28 PM

I have come to the conclusion that welders and trips don't go together.

I have a MAG welder at work that trips when the wire touches the work for the first time.

Reset the trip and it's fine for the rest of the day.

My new Miller in the garage trips if I switch it off slowly. If I whack the switch across quickly it's fine.

Grinding dust inside a welder causes probs.

If you have the older type H/F contacts mounted on an insulating block, it's worth a strip down.

Sand the block to remove the burnt on dust and reassemble.

H/F tracks through anything.

Paul G