Does anyone know either who sells these, or what the offical name for them is so I can search?

This is a tool that can form a raised lip on thin wall tubing such as that used in cooling systems, to prevent a rubber pipe slipping off when secure

with a jubilee clip etc. I've seen a picture of one ages ago, so I'm sure these do exist (and not just in my imagination!).

The ones that I have seen are in the Frost catalogue.

They call them Bead Form Tools.

Very nice but quite expensive (£400 ish), so only really an option if you are doing loads of them.

www.frost.co.uk

Alternatively, Car Builder Solutions will make them up for you.

Regards

Mike

Just to answer myself they are called "tube beading tools" and they are very, very expensive.

A locost method is to modify the jaws of a pair of vice grips to put a groove in one and a matching lip on the other.

pop rivet the end of the pipe

hey presto

As zxrlocost says rivets work a treat

I think Rorty's bead roller plans include dies for

beading tube.

http://www.rorty-design.com/content/bead_roller_plans.htm

Earls tubing supplies in Uk do some cost effective tools to bead piping. I have one and it is excellent.

http://www.earls.co.uk

[Edited on 4/1/06 by Terrapin_racing]

[Edited on 4/1/06 by Terrapin_racing]

Rescued attachment 00tube.jpg

Wasn't there a post on here a year or so ago about a home made beading tool ?

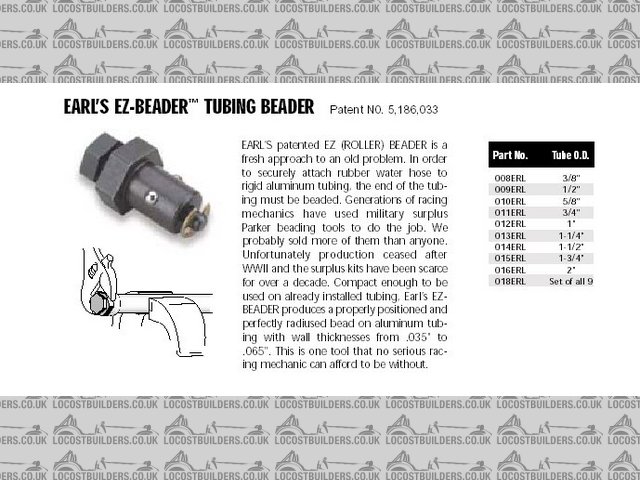

and further details from Earls catalogue

I have used very successfully on mild steel tube also

[Edited on 4/1/06 by Terrapin_racing]

Rescued attachment 00tube1.jpg

If its copper pipe, solder a socket on the end

IIRC someone suggested using a pair of mole grips....

weld a bead along the lower jaw and file a matching chunk out of the upper jaw. then just 'crimp' the pipe in stages all the way round.....

you could do what this turbobricker did !!

http://forums.turbobricks.com/showthread.php?t=58790&highlight=bead+maker

or you could contact allyfab, bryn is a great bloke with great prices and good service.

(yeah, i'm a happy customer)

A tip I picked up is to anneal the pipe first to reduce risk of cracking.

Molegrip dodge sounds feasable and I might try that.

Apparently you can get the same security by flaring the end out gradually with a small open ended spanner - not as pretty though.

I did mine this way

http://www.locostbuilders.co.uk/viewthread.php?tid=14691

excellent solution volvosport....

for those to lazy to follow the link......

surely one of our enterprising chaps on here could start knocking out the wheels on a lathe ? I'm sure they would sell....

clearly the two rollers are brought closer together by doing up the vice but how are they held to the vice jaws?

Now this has got me thinking - for those without a lathe, how about using some large penny washers with smaller ones for the recess welded to each

other?

Drilled and tapped into the sides of the jaws or maybe welded?

Might be worth using a couple ol lengths of angle iron to fit in vice jaws with a plate welded on the end drilled and tapped to take the bolts . quick and easy to fit into place . Think i'll try it out tomorrow if I get time.