Welding a stainless tank.

Big Stu - 14/7/05 at 09:19 PM

Hi All,

I am planning on building a fuel tank for my new project out of stainless. It will be a very basic design, simple cube.

How easy is it to weld stainless using a standard mig welder? How much is stainless wire?

Is this a good idea or should I get someone to make me an aluminum one?

Hellfire - 14/7/05 at 09:22 PM

The latter...

Big Stu - 14/7/05 at 09:25 PM

know anybody?

mangogrooveworkshop - 14/7/05 at 09:30 PM

Hugh Paterson does them time to time

welderman - 14/7/05 at 09:45 PM

Find yourself a nice engineering firm with a tig welder, they would be happy to weld it for you for a small fee.

Well we would anyway.

Depending on thickness of st/st sheet your using i personally would not use the mig, but try .8mm wire and move pretty fast with the gun.

mark chandler - 14/7/05 at 10:18 PM

Tigs the way to go, for a clean job you need to flow gas both sides of the weld.

Trouble with MIG is cold start, micoscopic holes as you strike the arc, even using ordinary steel you will struggle.

Whats your location ?

Big Stu - 14/7/05 at 11:12 PM

Central Scotland but up and down to east anglia all the time

907 - 15/7/05 at 08:11 AM

Hi All,

If you make it from flat peices and weld the corners it will distort,

plus the more welds you have the more chance of leaks.

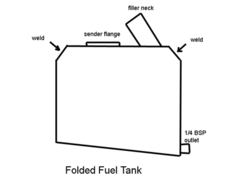

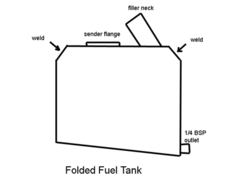

I made mine from 1 mm 304 and folded it with the weld

seams between the 45 deg bends, (see pic).

The rear of my chassis isn't parallel to the ground,

hence the shape of the bottom of the tank.

I welded the sender flange & inlet to the top first, then welded

the long seams, as Mark says, with backing gas.

Folded baffles were then slid inside and spot welded,

then mounting straps, again spot welded, then the ends fitted last.

The top did ripple a little bit but not too bad.

You could plug weld instead of spot welding, and yes, Tig is the way to go.

Err, sorry, I'v probably put you off.

atb

Paul G

Rescued attachment fuel-tank-s.gif

johnjulie - 15/7/05 at 08:21 AM

AS already mentioned, find a good Tig welder, it requires gas on both sides of the weld to ensure a good clean weld, plus you won't have the

distortion problems.

Cheers John

alfasudsprint - 16/7/05 at 11:43 AM

I had mine made, for free! from stainless, fully welded, no folds, flat top slanting bottom to accomodate chassis, filler neck a curve. Worked very

well, some distortion in tank from heat but ok.