Or you can use the compound slide.

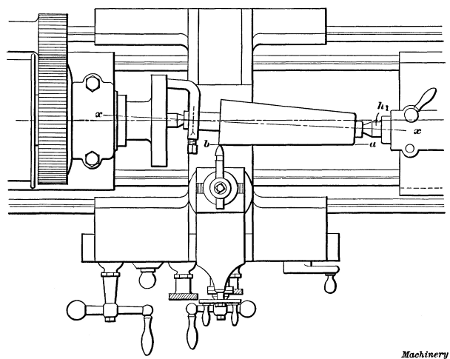

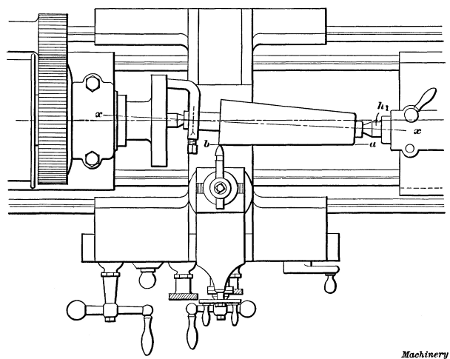

For the radius you could use a ball turning attachment .

[Edited on 27/5/14 by big_wasa]

Managed to buy an ML7 a couple of years ago. ( Wish I had done it 10 years ago when I retired but that is another story ). I have learned to do basic turning and boring and am now about to attempt tapers, but I aspire to make some intake trumpets with bell mouth openings. How do I do this? Do I need to grind a special tool or is there a trick to use a single point tool to execute a radius in the horizontal plane? I cannot figure this out. For info I have a 4 position turret type tool holder. TIA.

If turning between centres you can offset the tailstock.

Or you can use the compound slide.

For the radius you could use a ball turning attachment .

[Edited on 27/5/14 by big_wasa]

Have a look at this series of videos - Tubelcain - I know the lathe is an Atlas but it's

very similar to yours.

Also this may be helpful

I thought trumpets spun using a bending technique (tool) while spinning the job?

Have a look for a "Ball Turning Attachment"

Trumpets are a lot better spun rather than turned. And a lot quicker.

Well, I need to look into the dark art of spinning as well, another skill I do not have. Thanks for the advice and links folks.

Well if you make a former from alloy you could then lay them up in carbon fibre.

This may help with your trumpet design :

Trumpets

quote:

Originally posted by big_wasa

Well if you make a former from alloy you could then lay them up in carbon fibre.