make your own MIG welder

binraker - 7/9/04 at 06:41 PM

i wasn thinking (every one cowers behind piles of sandbags with tin hats on) a MIG welder is just and arc welder with a gas supply and a wire feed. a

gassless Mig uses flux cored wires so all you would need to make a gassless mig from an old arc welder would be the torch (makeable but also probbably

a cheap spare) and the wire feed (again, could be built from bits or a pile of spares)

anyone see any problems with this, like overriding cost and AC/DC issuse?

binraker - 7/9/04 at 06:42 PM

and if you havent got the arc welder to start with i have seeen them built withtthe HT transformes from microvwaves (use secondary as primary)

Chris_R - 7/9/04 at 06:52 PM

I have a BOC Migmaster 130 and have recently replaced the tourch. It cost £70 + fitting (which I managed to get free in the end).

Peteff - 8/9/04 at 10:31 AM

http://www.johndavies.co.uk/newtorchmig.htm

These are good prices, you could get one and take the euro fitting off the welder end.

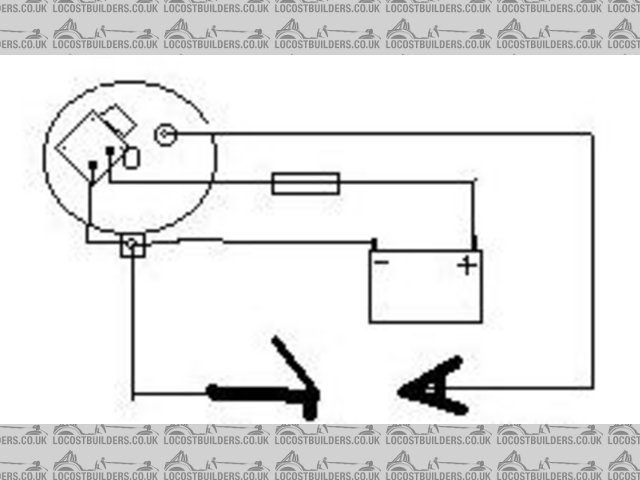

Hugh Jarce - 9/9/04 at 06:53 AM

What about using a car alternator and an electric motor or petrol engine to drive it? You would need a battery to energise it and a dimmer switch to

vary the output. The motor would need to be at least 5hp to keep the alternator spinning at 6500-7000 rpm. This won’t harm it at all, as they’re

designed for these speeds, and rated at 100% duty cycle.

You could use it as an arc welder and a TIG for which you’ll also need a 125 or 150 amp air-cooled TIG torch with a built in gas valve, some 1.5mm

(1/16" 2% thoriated tungsten electrodes, aluminium gas cups, collets and collet bodies.

2% thoriated tungsten electrodes, aluminium gas cups, collets and collet bodies.

I read about someone who hooked a 130 amp alternator up to the frame of his compressor and drove it off the compressor motor.

Powerful enough to weld anything you are likely to come across in a Locost.

Rescued attachment diagram.jpg

binraker - 9/9/04 at 05:02 PM

now theres an idea...

i like it, must try it at some point need both the motor and the altenator.

who said rotary transformers were old fashioned!!

niche - 18/3/07 at 11:29 AM

Hi chaps,

Just joined and an interesting site, about

to browse other threads...

I'm curious if anyone has had any success

and I've been thinking about using car

batteries and a large inductor along

with some power switching devices.

This would allow high current operation

for short periods to 200Amps or more

and off a single phase supply...

[Edited on 18/3/07 by niche]

flak monkey - 18/3/07 at 11:39 AM

You can make a stick welder from 3 car batteries in series. Gives you a 36v OC voltage (about the same as most decent arc welder) and the abilty to

provide upto 200+amps DC.

Pretty commonly used in the back of beyond for quick repairs.

Obviously you could creat the same effect to use as a TIG welder if you wanted to.

David

niche - 18/3/07 at 11:46 AM

Yeah thats what I was thinking with

exactly 3 car batteries but, wouldnt you

need some sort of sizable inductor to

generate enough volts for a sustainable

arc ?

I was mainly interested in it because I

dont have 3-phase power for the larger

migs and I think I need a sizable current

for some aluminium work I can do, plus

to experiment with...

Peteff - 18/3/07 at 12:55 PM

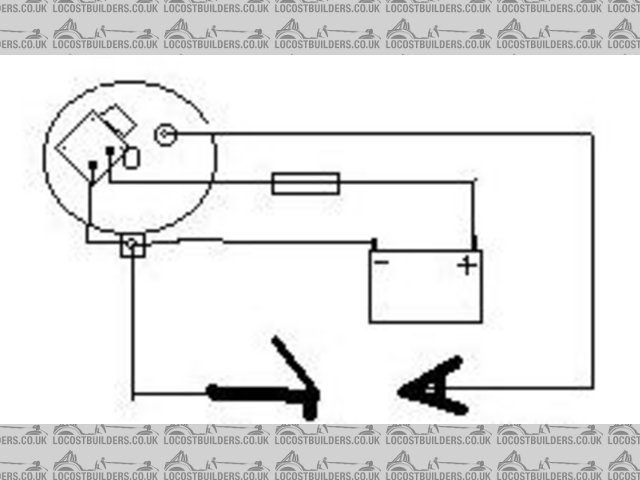

There were some pictures of what he did, like this

Rescued attachment alternator3.jpg

CairB - 18/3/07 at 08:20 PM

Rawlplug used to sell a stick welder in the '70s that ran from car batteries. It had a solenoid in the head that would retract the stick to

create the arc as soon as current flowed. I think I only disposed of mine on a recent clearout.

It used to be quite effective, especially when on 3 batteries, but I do remember the day that one of the batteries exploded when welding. I'm not

sure which was worse, the ringing in my ears or the cloud of sulphuric acid hanging in the air.

Peteff - 18/3/07 at 08:49 PM

My mate had one of those, it worked on an arc welder in place of the rod holder and it looked like a Dan Dare ray gun  . It did actually do the job

though.

. It did actually do the job

though.

Mark Allanson - 18/3/07 at 10:11 PM

In DC mode it was just an electrode holder, in AC mode it had a glorified door bell which vibrated the electrode at 50hz so even very inexperienced

users could stick weld without sticking. In the trade it was known as the parkinsons

2% thoriated tungsten electrodes, aluminium gas cups, collets and collet bodies.

2% thoriated tungsten electrodes, aluminium gas cups, collets and collet bodies.

. It did actually do the job

though.

. It did actually do the job

though.