First time welding

rb968 - 26/2/12 at 08:37 PM

Managed to borrow a bloody huge welder from a mate to have my rollcage welded in over the next week or so (don't worry I am not doing this myself

! as the following images will evidence!). Came with a bottle of Argoshield light and a mahoosive reel of wire.

Borrowed welder

So thought I would have a practice myself once it was setup on various bits of scrap I had in the garage.

Description

First efforts were frankly poor as the autodimming mask was a new experience and set too dark so I kept wandering.

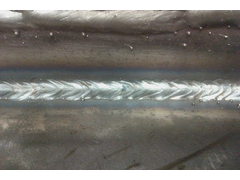

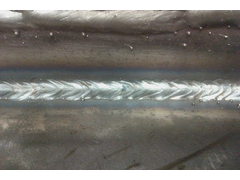

Started on 3mm mild steel plate. Top was a butt weld and my first series of mostly blind efforts. Bottom one was 3rd continuous weld.

Description

I was pretty happy with it.

Description

Ended up cutting and welding various bits of steel and some exhaust tube to try welding different thickness'.

Description

Description

Then had a go with thin wall 20mmx 1.25 box and some 16 x 1mm tube.

Description

All comments welcome. Basically I started with the settings under the cover on the welder. Only experience is previously having a go with an old

Snap-on welder my Dad had which was knackered. I have spent a lot of time talking to and watching the welder at work but he tig welds normally.

Anyway, enjoyed trying to learn something new. Blew a few holes in the thin wall stuff and travel speed took some time to get right (or better

anyway!)

Rich

designer - 26/2/12 at 08:40 PM

If that is your first attempt, then it's bloody good!!

loggyboy - 26/2/12 at 08:42 PM

quote:

Originally posted by designer

If that is your first attempt, then it's bloody good!!

+1

daviep - 26/2/12 at 08:45 PM

Very good for a first effort

Current is a tiny bit high on the 3mm plates, that's what is giving you the small amount of spatter and you can see in pic#4 that there is a bit

of under cut at the side of the weld. Nothing too much to worry about just to let you know what causes it.

Cheers

Davie

rb968 - 26/2/12 at 08:46 PM

Genuinely my previous effort was basically tacking bits together for the welder at work to then sort out with his tig. Bird sh1t does not begin to

describe It as the wire feed tensioner had broken and we had to push down on it with a piece of wood. Having some decent kit made a lot of

difference.

YouTube videos were a big help as well believe it or not.

rb968 - 26/2/12 at 08:49 PM

Cheers Daviep, my first attempts seemed to be sitting on top of the plate so I turned it up another notch. Is I better to use a lower power but move

slower then?

ashg - 26/2/12 at 09:36 PM

great first welds, mig is pretty easy if you have got good kit.

[Edited on 26/2/2012 by ashg]

bonzoronnie - 27/2/12 at 10:28 AM

Looking great for first time welds

Been having a look at picture 3 & can't quite tell if you are left or right handed ?

If you are right handed, try pushing the weld from Right to left ( Travel Right to Left ). This is the usual correct direction of travel when using a

MIG welder

Of course vice versa if you are left handed.

Give it a try & you should see improved results.

Great start though

rb968 - 27/2/12 at 12:26 PM

Right handed and I was pushing from right to left. (edited as the top weld in photo 3 might have been done with the plate the other way round.....it

was my first efforts. Can't recall.

Perhaps mistakenly I was working in a circular motion looping back on myself as I travelled along.

This is probably wrong and something I had seen a video on.

Just showed my efforts to the welder at work........

He was very kind.... but suggested I can just run the weld along a butt joint and not bother with any side to side motion. He also repeated what

Daviep said about too much current so I was getting an undercut visible at the edges of the weld. More wire less power or just less power.

My colleague asked if I had been welding under a flock of seagulls which I thought was harsh!

Any advice gratefully received.

Rich

[Edited on 27/2/12 by rb968]

Mad Dave - 27/2/12 at 08:50 PM

quote:

Perhaps mistakenly I was working in a circular motion looping back on myself as I travelled along

This could be causing any undercut you might be getting as you are pulling and pushing the molten pool