Matt

Rescued attachment IMG_5386.JPG

Morning everyone,

Finally onto rebuilding my engine which is a zetec silvertop and I've got a couple of questions about mouting it to my engine stand if I may.

I only really have 4 possible bolt holes all of which appear to be 10mm - that is the cylinder head bolts fit in them (which are T50 I think from

memory). Two of the holes are threaded and two are straight through (I think they are locating lugs for the bellhousing). The cylinder head bolts

when screwed as far as they will go into the threaded holes stick out to far past the stand mounting to make them useable.

So my only fixing option bolt wise seems to be M10 x 80mm, two into the threaded holes with washers, two through the non threaded holes with

washers/nuts.

My questions are:

1) Does this seem ok ?

2) Could I use the cylinder heads bolts in the non threaded hole and use M10 nuts with them ?

3) M10 to me doesn't seem a lot to be holding an entire engine on with - is there a risk of stripping the threads or anything else I should be

looking out for ?

thanks

Paul

Those locating lugs are threaded.

Darren

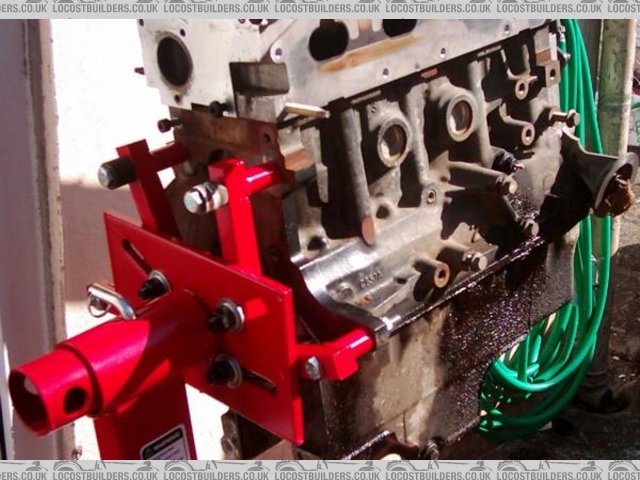

It's how I'm doing it with same engine. I used 4 off M10 x 100 bolts to fit the engine to my stand. 2 into the threaded holes and two

straight thru with washers and nuts either side. Been mounted for several weeks and pushed all around the garage with no issues. Be careful when

rotating the engine though!! You can just see 1 of the botls in the attached pic. HTH.

Matt

Rescued attachment IMG_5386.JPG

Great thanks to both of you.

Above works fine for me too.

Rescued attachment zetecrear.jpg

I used threaded rod when i did mine,.

quote:

Originally posted by Danozeman

I used threaded rod when i did mine,.

Dunno if you can see it but i used the offside block mountings as I wanted to fettel the ali housing.

Great thanks everyone

Never thought of mounting it "sideways" coozer !!