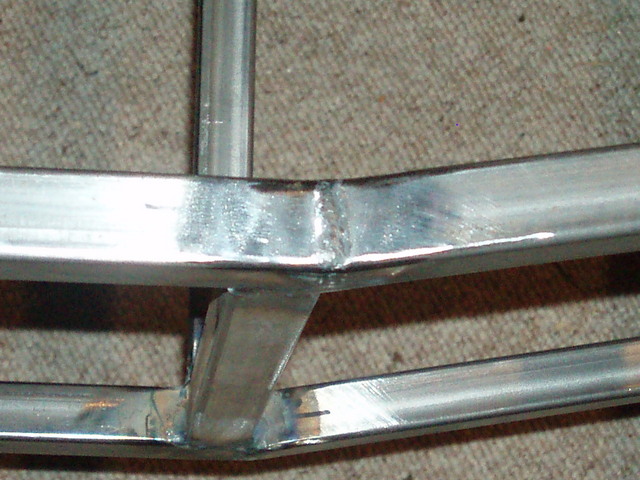

My first go at tig welding

big_wasa - 26/5/09 at 08:26 PM

Ive had the tig a good 18 months and even had the gas 6 months.

Any way first atempt, and then second.

On the first I kept diping the tungsten. This balled up and really spreads the weld pool out.

The second atempt I managed to dip it less and keep it more focused.

I love the way you have so much more control than with a mig.

Lots more practise needed but I am chuffed for a first go

I want to upgrade to Ac now with a water cooled torch.

Any tips ?

big_wasa - 26/5/09 at 08:26 PM

doh pic

r1_pete - 26/5/09 at 08:29 PM

Mmm, nice, similar job to one I balls'd up last year when I welded the runners on the wrong side of the plate.

I'm seriously considering an ac/dc tig, and ditching the mig & oxy acetylene, looking like best part of a grand for something deent

though.

[Edited on 26/5/09 by r1_pete]

deezee - 26/5/09 at 08:40 PM

Looks nice. Hell of alot better than my 1st try. Took me ages to get to a point where my welds were'nt looking like bird crap. What gas are

you using? looks like a MIG welding gas. Has that CO2 / oxidising discolouration look to it.

big_wasa - 26/5/09 at 08:44 PM

Its Argon. I guess I used to much heat ?

Whats the better value money wise.

Practise practise practise (lots of gas)

or

Get a few lessons?

[Edited on 26/5/09 by big_wasa]

blakep82 - 26/5/09 at 08:45 PM

very nice

MakeEverything - 26/5/09 at 08:59 PM

I use CO2 from an old fire extinguisher. It runs a bit hot, but for this thickness of metal it should be ok. You might burn the tungstens out a bit

more often though. I welded most of my chassis and used 4 1/2 tungstens and two large extinguishers i think.

Sample Weld

[Edited on 26/5/09 by MakeEverything]

NS Dev - 26/5/09 at 09:50 PM

quote:

Originally posted by big_wasa

Its Argon. I guess I used to much heat ?

Whats the better value money wise.

Practise practise practise (lots of gas)

or

Get a few lessons?

[Edited on 26/5/09 by big_wasa]

practise would be my advice. Judging by your first attempt you already know the basics, there's nothing wrong with what you have done, and the

only thing that will improve appearance is practise.

ashg - 26/5/09 at 10:47 PM

looking at the red oxidation you have the gas up a little high. you want a no5 ceramic with 1.6mm tungston running around 4-5lmp of gas for that kind

of work.

also try bringing the amps down an little so you have time to feed the rod more slowly. this will allow you time to build up the weld a little

more.

to be honest its a very very good first attempt and will do what you set out to do. cosmetics are something that come along later.

i have an ac/dc unit and dont know how i would live without it. if you plan to do a lot of ali welding make sure the welder you buy has not only

balance control but balance and square wave adjustment. a good high work bench and a pedal also makes life lots easier also

just make sure you cover your neck when working on a bench as the light has a habbit of reflecting up from the bench and buring it.

smuty - 27/5/09 at 07:58 AM

after a bit of practice

Rescued attachment 053.JPG

nstrug - 27/5/09 at 08:50 AM

What to aim for:

http://www.yellowbullet.com/forum/showpost.php?p=1282128

big_wasa - 27/5/09 at 03:23 PM

Best learn to walk before running.

God them wishbones look good

cheers