Steel or ali?

Send me a drawing and I'll have a go

How long Alex? 17mm OD X 11mm ID x ??mm long.

Plenty of steel stock here.

Steve

[Edited on 19/4/09 by coozer]

[Edited on 19/4/09 by coozer]

I have an alternator pulley with 17 mm hole that I would to fit onto an alternator with what appears to be M14 spindle.

I am going to buy a M12 stud connector and attempt to turn it down (by filing in a drill press) as well as drill the hole and tap to M14 x 1.5.

This may not be successful, so if I fail, is there anyone out there with a lather that can do this?

Namely drill a 11 mm hole and turn the outeer down to 17 mm OD?

I will supply the stud connector (a very long hex nut) and can post the 11 mm drill if you do not have one.

Yes, I realise M12 thread will eat up a bit of the M14 1.5 mm thread but I'll risk that.

Plan would be to turn a piece of steel, 17 mm OD and with 11 mm hole.

Anyone able to do this? (II doubt such a thing exists)

Just had a look at this tonight.

Is the pulley and shaft tappered ? it is on the denso alt' I looked at tonight.

I may be able to do it... if I have an 11mm drill...

Steel or ali?

Send me a drawing and I'll have a go

How long Alex? 17mm OD X 11mm ID x ??mm long.

Plenty of steel stock here.

Steve

[Edited on 19/4/09 by coozer]

[Edited on 19/4/09 by coozer]

Are you planning to move the pulley out from the alt' as that would be a bad idea. imho

You would be better with a sleeve 11mm inner and 17mm outer.

quote:

Originally posted by big_wasa

Are you planning to move the pulley out from the alt' as that would be a bad idea. imho

You would be better with a sleeve 11mm inner and 17mm outer.

I still think the pulley and shaft are tappered.

quote:

Originally posted by big_wasa

I still think the pulley and shaft are tappered.

quote:

Originally posted by 02GF74

I am going to buy a M12 stud connector and attempt to turn it down (by filing in a drill press) as well as drill the hole and tap to M14 x 1.5.

u2u

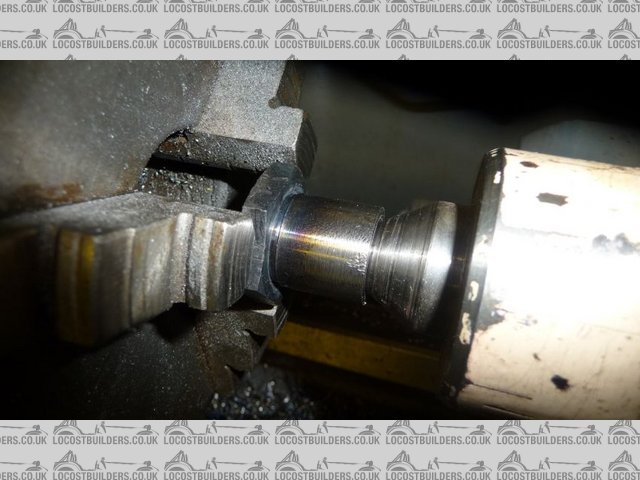

Nearly there, just need to turn the diameter down and get the correct length....

Rescued attachment M14 Threaded.jpg

Brill - that looks awesome ...