T&@G ? how to?

02GF74 - 5/1/09 at 10:23 AM

not really into woodworking but need to make a door frame. Current one has what I think is "tongue and groove joint"?

Due to size, the tools I have to make this is saw, chisel and drill press.

Adive and tips on how to make this.

I presume I mark the joint, taking into account of the saw wdidth.

Do I make the tongue or grovve first? ( I guess the groove as it will be easier to trim the tongue width down.

How do I ensure the saw follows the lines in the groove - go slowly and make many checks ans the cut is made?

Also for the groov - I plan to drill a big hole at the bottom of the groove that meets the saw cuts, then tidy up with a chisel.

Good plan or just lay one on top of other and use metal straps?

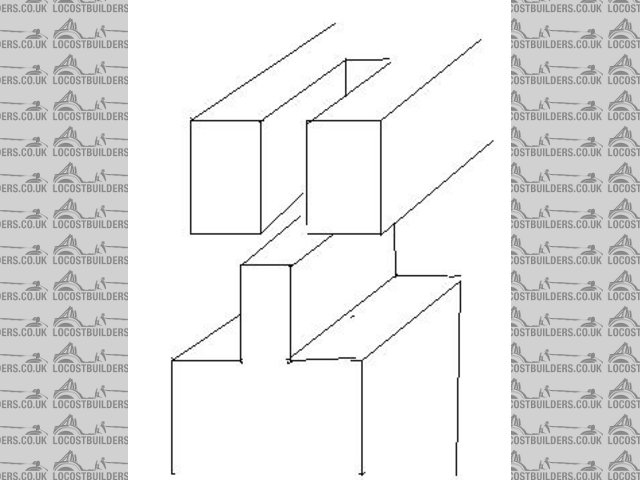

Rescued attachment tng.JPG

Guinness - 5/1/09 at 10:26 AM

Is the frame a special size?

If not I'd be tempted to go down to Howdens / Magnet or even B&Q and buy a standard frame from them. B&Q want £14 for a 1981 x 726 x 114

door frame.

Cheers

Mike

stevec - 5/1/09 at 10:28 AM

Linky for mortise and tenon joint stuff.

linky

Steve.

[Edited on 5/1/09 by stevec]

02GF74 - 5/1/09 at 10:32 AM

ARRGGGGHHHHHH!!!!!

now why didn't think of that

but too late now as I have the wood and cut it is shape using I router I do not have as well as being painted in primer

Is is a garage side door that is not as tall as "standard" door and may be narrower.

nick205 - 5/1/09 at 10:33 AM

quote:

Originally posted by Guinness

Is the frame a special size?

If not I'd be tempted to go down to Howdens / Magnet or even B&Q and buy a standard frame from them. B&Q want £14 for a 1981 x 726 x 114

door frame.

Cheers

Mike

I'll 2nd that!

You'll spend hours messing about making your own.

Peteff - 5/1/09 at 10:48 AM

If it's for the garage I'd have cut it at 45° and nailed it together. Screwing it to the wall will keep it firm.

Mr Whippy - 5/1/09 at 11:12 AM

quote:

Originally posted by nick205

quote:

Originally posted by Guinness

Is the frame a special size?

If not I'd be tempted to go down to Howdens / Magnet or even B&Q and buy a standard frame from them. B&Q want £14 for a 1981 x 726 x 114

door frame.

Cheers

Mike

I'll 2nd that!

You'll spend hours messing about making your own.

yip thats what just I fitted too, their a bargan really

neilj37 - 5/1/09 at 11:49 AM

You can also buy a special dril / chisel that fits into a drill press that works a treat !! Easier than trying to use a chisel to form the slot.

Personally I do all mine using a router and template i made. Also works great for doing the hinges

Valtra - 7/1/09 at 11:12 PM

If what youre after is indeed a mortice an tennon joint in the frame corner then Idealy you will need a marking guage, a tennon saw , pencil, ruler, a

couple of sharp chisels , a mallet, a tri square (or a good square template , factory cut mellamine is usualy very acurately square) and several

sticking plasters and copious running water to wash the sawdust out of your eyes . I speak from many years of experience starting with the trip to

casualty following my woodwork "O" level exam (passed with a B)

good luck

ahh the diagram has now apeared a simple open mortice , make sure you allow saw width in your marking up and make sure the tennon is plenty fat enough

to start with,then you can always shave it down with a good broad chisel till it fits nice and snug. The sense of achievement is why we do these

things if not we'd all drive factory made cars

[Edited on 7/1/09 by Valtra]

02GF74 - 9/1/09 at 09:54 AM

^^^ yep - re: sendse of achievement .... until it goes t*ys up!

I looked in my BIG BOOK of EVERYTHING and it is know as a "bridle joint"

and the book more or less describes the process much as I tough.

need to pop out at lunchtime to buy a marking guage and a tenon saw.

Valtra - 9/1/09 at 12:13 PM

Bridle joint eh ....get you with your fancy terms

Valtra - 10/1/09 at 05:41 PM

Is that a cat or a boxer dog in a cat costume ?