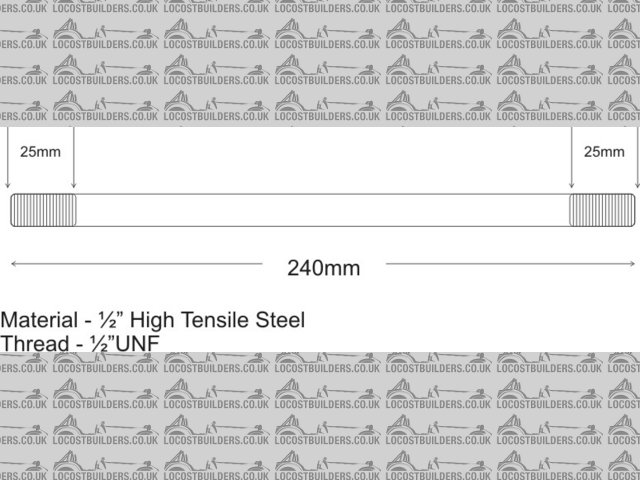

I need some 1/2" x 240mm high tensile bar with 25mm of 1/2"UNF tapped each end. Preferably plated but hey - beggars can't be choosers!

Beer tokens waiting

[Edited on 27-2-06 by RazMan]

... to turn me a couple wishbone pivots.

I need some 1/2" x 240mm high tensile bar with 25mm of 1/2"UNF tapped each end. Preferably plated but hey - beggars can't be

choosers!

Beer tokens waiting

[Edited on 27-2-06 by RazMan]

I can do that for you Mike but need to source the material from somewhere.

What was the name of the Hydraulic people in Colchester?

Brian you are an absolute star!

Anglia Hose & Hydraulic - 263 London Road near the garden centre.

Tel: 01206 212168

[Edited on 27-2-06 by RazMan]

ERM if you tap 1/2 inch round bar with a 1/2 inch tap then surely you'll need the optional box of invisible air threads

Methinks there's a typo somewhere.

Ahem - you are quite right of course

A die might be better in this instance

AH it all makes sense now

Rescued attachment Suspension pins.jpg

Mike the best I can find in 1/2 inch is some silver steel.

Not exactly high tensile. From memory its a high carbon steel with about 1.5% carbon, about .5% chromium and a touch of Manganese as well.

Generally used for shafts etc. in its un-hardened state but when hardened can be used for all sorts of things. Punches dies and cutting tools to name

but a few.

It should be ok un hardened I think but perhaps some others with more application knowledge will advise.

I remember from my school days that silver steel is tougher than mild but otherwise I'm a complete numpty on such matters so I would have to rely on the knowledge of others too.

Silver steel is:

About 1.2% carbon, 0.45% chromium, 0.3% manganese.

Its very brittle if hardened, but can be tempered, not an easy job to do accurately at home though.

As for the specific properties of it, do a search on google, i am sure it will turn up what you need.

Probably the best or easiest thing to do if you cant get any HT bar is get some oversized HT studding and turn it down and recut threads on it. Bit of

a guff way around it, but if its the only way...

David

[Edited on 28/2/06 by flak monkey]

quote:

Originally posted by flak monkey

Probably the best or easiest thing to do if you cant get any HT bar is get some oversized HT studding and turn it down and recut threads on it. Bit of a guff way around it, but if its the only way...

If you wanted to try that idea you would need to go upto M16 studding to start with. As its got a core diameter of 13.5mm, and you need an OD of

12.7mm

Stainless - Been there several times. Its no where near the strength of HT bolts...sorry. Fatigues quite badly as well I think.

David

[Edited on 28/2/06 by flak monkey]

We may just have some big cap heads laying about but not sure about the length. I don't really want to use silver steel it's evil stuff to

machine. Leave it with me Mike.

By the way I got my hose end done £6.00 really nice people too.

I didn't think that it would be such a pain to find the right material - or am I over speccing the stuff?

Bearing in mind these pins will be supporting each corner of my car (along with shocks & wishbones) can I get away with a lower spec?

quote:

Originally posted by BKLOCO

We may just have some big cap heads laying about but not sure about the length. I don't really want to use silver steel it's evil stuff to machine. Leave it with me Mike.

By the way I got my hose end done £6.00 really nice people too.

Are they 12.9? Most of the ones I've used have been.

I,ve got your wishbone pivots Mike.

I'll bring them round in the morning.

How did the plastic bending go?

Woohoo!

That's brilliant Brian! I'll be around all day.

I havent had a chance to look at the plastic bending yet - I've been bending ears at Aeon today about my front section. It really exists  but

it is still not finished and all I get is 'ready next week'. Trouble is it has been 'next week' since Xmas!

but

it is still not finished and all I get is 'ready next week'. Trouble is it has been 'next week' since Xmas!

Got my doors to play with now anyway so it isn't all bad.

At the risk of upsetting people, here we go.

You seem to be concerned about the shear strength of the wishbone pivot. From memory the shear strength is generally asumed to be 60% of the tensile

strength.

Before spending 'hard earned' it may be worth considering what this pivot, (a 12mm bar), is attachet to:

I'm guesing but how about:

A 3mm mild steel braket attached to a 1.2 / 1.5mm RHS box section.

Under these conditions which do you think the more likely to yield?

Mick

Your'e not upsetting me Mick it's a very valid point.

Unfortunately the issue wasn't really the material spec as much as the fact that Mike couldn't find a supplier of 1/2" UNF bolts longer

than 8" and he needed 81/2" to get the nut on with 2 full threads showing past the nylock to keep Mr SVA happy.

I agree than a lump of EN1a would probably be strong enough in this application (especially in double sheer) but it's not good practice.

Brian.

.............. and I'm just happy to have my front end firmly supported on non-bendy bolts