Trike roll oversteer

smart51 - 4/6/13 at 09:37 PM

I've recently built a trike with 2 front wheels and one rear. The rear being a whole scooter rear end. It weaved at speed and I guessed the

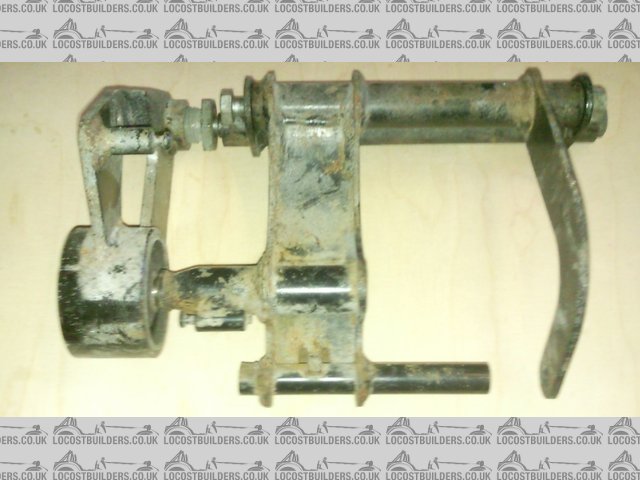

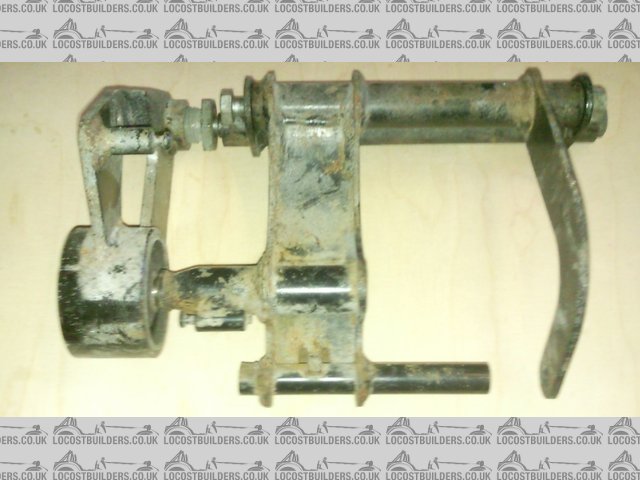

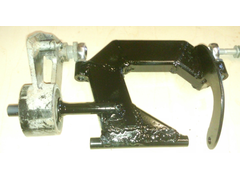

scooter trailing arm wasn't up to the job. So I made a new one, swapping from this...

Piaggio swing arm

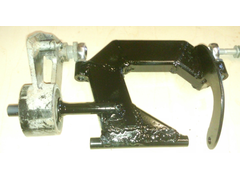

to this...

My replacement swing arm

The result is more different than an improvement. It is less twitchy but more dramatic. It still wants to go one way or the other instead of

straight ahead, though less so. It's worse when turning.

When turning into a corner, the trike initially turns in from the front. As the trike rolls, the rear starts to pull out and the rate of this

increases with increasing lean. In long fast corners the rate of change becomes quite rapid and you have to steer out of the corner to hold the line.

Lift off and the trike darts the other way. I'm guessing it is roll oversteer. Is this how a trike normally handles?

The whole thing weighs under 240kg and has a Fiat Cinquecento front ARB which I thought would be more than enough. However, if I put my feet against

the rear wheel, hold on to the roll over hoop and lean out, the trike leans over by about 10° or 15°. I don't know what to do to fix it. Any

ideas?

ali f27 - 4/6/13 at 09:45 PM

sounds to me like a front end prob at a geuss to much roll on front need bigger wieght springs to take out roll and stop rock and roll steering sounds

like steering through wieght transfer but need to think on it bit more

v8kid - 5/6/13 at 02:21 AM

My first reaction was its rear end steer. I'm not sure how the rear suspension works but assume that the big rubber doughnut will allow the rear

wheel to steer- a very small movement is enough can you test this with long levers?

Cheers!

v8kid - 5/6/13 at 02:26 AM

Where does the wheel go?

Slimy38 - 5/6/13 at 05:26 AM

Take a look at MEV's tR1ke pictures here;

http://www.roadtrackrace.co.uk/rtr_tr1ke_gallery.html

There are a couple of it going round quite a tight corner, with the suspension looking like it's almost bottoming out on the outside wheel.

Without actually measuring, I'd say their car uses at least 10 degrees of roll, so I'm not sure dialling out the roll will make that much

difference.

I would be more inclined to see what's happening on the rear. This might be a silly question, but when you're at maximum roll, could you be

losing rear traction? I'm guessing a moped tyre isn't going to be that big, and while it's not exactly heavy it's still more than

the original moped was carrying.

smart51 - 5/6/13 at 06:13 AM

The rear suspension is a trailing arm. The small tube and the curved arm connect to the engine and wheel assembly through rubber bushes. The rod

ends connect to the chassis. The rubber donut allows the engine to move up and down by a centimetre either way. I'm guessing to allow for

torque reactions.

The weight o n the rear wheel is the same as it was on the scooter. The extra weight is over the two front wheels. 250cc scooters are heavier than

50cc mopeds. There's no sign of losing grip from either end, even if I chuck it into the corners, though I could be wrong. Frone tyres are

135s, rear is 140 but curved.

Slimy38 - 5/6/13 at 07:12 AM

quote:

Originally posted by smart51

rear is 140 but curved.

Slightly deviating from your original question, wouldn't a standard car profile be a better tyre? Ignore me if you're already planning on it

being a future update.

The use of a scooter rear end makes a bit more sense to me now, I thought you had butchered a tiny little 30mph sewing machine!! Is there anything you

could adopt from the larger engined ones? I'd have thought Honda's 750cc beastie would need something substantial on the rear end. Although

a quick image search suggests they revert to a regular shaft drive for the bigger engines.

Just guessing here, is it possible it could be a problem with the basic front end setup feeling like a rear end problem? I'm the same as you, I

don't know how a trike should handle but I can imagine incorrect settings on the front could make things a bit twitchy. Are you happy with toe

settings, bump steer behaviour, etc?

[Edited on 5/6/13 by Slimy38]

smart51 - 5/6/13 at 07:35 AM

I'm planning to put a car tyre on the back when it needs changing. Perhaps it will improve things a bit but the severity of the problem makes me

think it's more than that.

I haven't ruled out the front end. There's no noticable bump steer (since I moved the steering rack). I tried toe out, parallel and a

little toe in before I made the new swing arm. It had a little effect but not much. I'm running 1° of negative camber at the front. I'm

wondering if +ve camber at the front would help neutralise what is in effect +ve camber at the rear. There is no camber gain at the rear with a

straight trailing arm.

v8kid - 5/6/13 at 08:02 AM

Ok get it now the whole engine/gearbox/wheel assembly pivots on the swinging arm.

I associate weaving and instability with rear toe out or in your case rear wheel steer but I guess you are saying that cannot happen However your

description of what is happening as you turn in to corner sounds very much like what happened with my car.

Strange!

MikeRJ - 5/6/13 at 08:15 AM

quote:

Originally posted by smart51

The rear suspension is a trailing arm. The small tube and the curved arm connect to the engine and wheel assembly through rubber bushes.

This is the bit that caught my attention. In the original application the swing arm won't see any significant lateral forces, so is it possible

these bushes are simply not up to the job? If this set-up is like I imagine it, any deflection in these bushes will lead directly rear wheel steering

under lateral loads, effectively causing over-steer.

How easy would it be to replace these rubber bushes with e.g. solid nylon bushes to prove (or eliminate) this? It may be that for longevity you need

to consider needle rollers as pretty much all larger bikes use.

[Edited on 5/6/13 by MikeRJ]

smart51 - 5/6/13 at 09:05 AM

The bushes are in the engine casing. I imagine they could be pressed out if you had the right tools. Looking at the numbers, if each bush compressed

by 0.75mm (they're quite small) then the rear "toe angle" would change by 0.5°. Multiplying that up, with the steering straight ahead

and the bushes compressed by this amount, the car would turn on a 300m radius, which is about what I am seeing. (I turn in, the car leans into the

corner, I turn out to compensate, the car goes round a 300m radius corner with the front wheels about straight). For info, 50 MPH on a 300m radius

corner = 0.4g of cornering force.

froggy - 5/6/13 at 10:52 AM

Based on how much movement I see when testing scooters your rear end must be flexing quite a bit under load .

blakep82 - 5/6/13 at 11:07 AM

quote:

Originally posted by smart51

The rear suspension is a trailing arm. The small tube and the curved arm connect to the engine and wheel assembly through rubber bushes. The rod

ends connect to the chassis. The rubber donut allows the engine to move up and down by a centimetre either way. I'm guessing to allow for

torque reactions.

The weight o n the rear wheel is the same as it was on the scooter. The extra weight is over the two front wheels. 250cc scooters are heavier than

50cc mopeds. There's no sign of losing grip from either end, even if I chuck it into the corners, though I could be wrong. Frone tyres are

135s, rear is 140 but curved.

Could be well off the mark here, but is the something in the back end that deals with cornering?

I know you've made your own rear arm, but presumably based on the original. Stick with me on this...

A car and I guess your trike, you steer right the body leans to the left slightly

A moped/scooter/bike, you turn right, you lean right

There something in the design of bike tyres or the arm that helps steer the bike the same way as it leans? Which in your case is the wrong way

Stiffen up the suspension would by my first try, and maybe some different tyres

ray.h. - 5/6/13 at 11:10 AM

imho. in my experience with scooter type suspension as opposed to motorcycle suspension. scooter engine/transmissions are quite softly mounted using

rubbers rather than nylon or hard plastic or even needle rollers. in a scooter application this is perfectly adequate with most of the loads in the

vertical plain. when using the same set up in a trike most of the loads are lateral which the soft bushes and mounts aren't designed to take.

replacing them with something stiffer seems pretty easy. my only concern is the increased side loadings on the engine castings once you take out the

damping effect of the rubber bushes.

smart51 - 15/6/13 at 03:39 PM

I've fitted an A frame to the engine casing using the mounts for the rear stand. The ends of the A frame are mounted to the chassis using rod

ends. The stability is noticeably better but still not quite right at speed. Clearly there was, and perhaps still is, a degree of rear steering.

I'll have another look later to see if there's anything else I can do to stiffen it up.

Ivan - 15/6/13 at 04:45 PM

Maybe I am miss-understanding your original post but it seems from your description that the problem is more when you are traveling straight than when

cornering, in which case I would guess that your problem is a serious amount of bump steer.

smart51 - 15/6/13 at 05:02 PM

The original problem was both straight and cornering. Straight seems to have been sorted now. There is no bump steer. I adjusted the rack position

until it went away while I was setting up self centering for MSVA. I can stand on the chassis and bounce up and down. The front wheels stay pointing

straight ahead. I think either there is still a bit of rear end movement or it is now actual roll oversteer.

MikeR - 15/6/13 at 05:09 PM

read this and remembered something a friend told of about riding a bike on the motorway. you get a flat spot as the bike is vertical. when you do your

first corner it can be scary as you go onto a narrow ridge of rubber so don't have masses of grip.. could the lean of the corner force you onto a

narrow strip of rubber.

smart51 - 16/6/13 at 01:48 PM

I may have been a little pessimistic yesterday. I've been for a quick blat across mixed roads and it is quite a lot better with the A frame. It

feels stable in a straight line except at 70 MPH and even then it just feels like it's very windy. Bear in mind that the top speed is about 75.

It handles lumpy urban streets with aplomb and is fun over speed humps because the rear wheel goes between them. No matter what the road defect, you

only get one bounce.

Give a quick but smallish turn of the steering wheel and it turns in quite nicely. But it as it rolls, which it does quite slowly, the radius of turn

tightens, and at an accelerating rate the more it rolls. It's not alarming but it's not "right".

I've checked the rear tyre and there's no sign of it flattening. In fact there are are a few scuffs off the centre which suggest a degree

of lean at the rear. I wonder if there could be some twist in the trailing arm as viewed from the rear?

Edited to correct the 'autocorrect' which can't be turned off

[Edited on 16-6-2013 by smart51]

smart51 - 17/6/13 at 07:57 AM

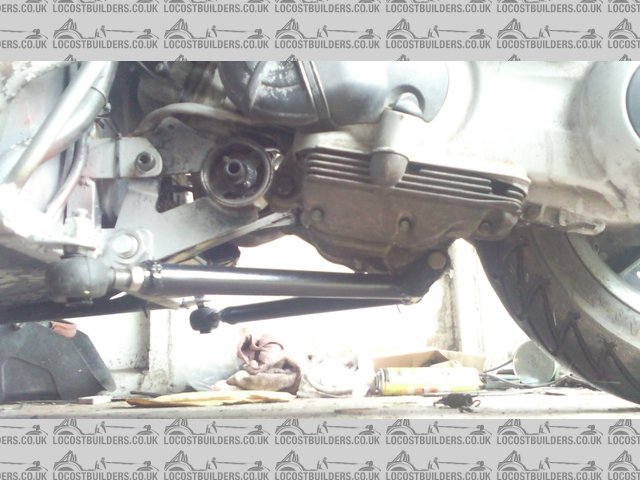

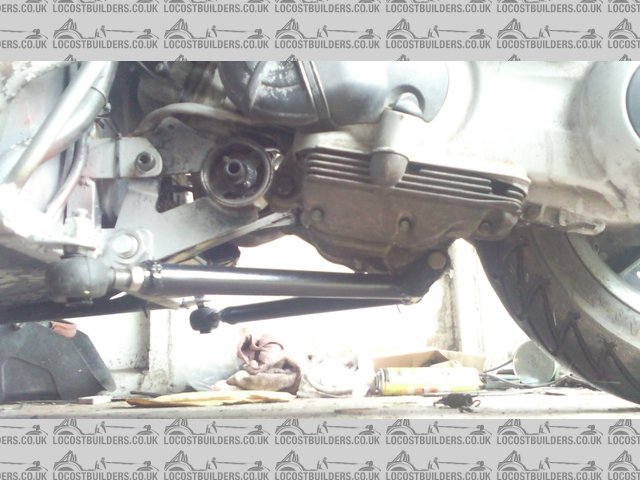

Here's a photo of the A frame in situ. If the whole engine / rear wheel assembly is leaning over in a corner due to twising of the mount, what

can I do to the A frame to stiffen it in torsion?

Rear suspension A frame

MikeRJ - 3/7/13 at 10:49 PM

It's not clear to me which are the original suspension bushes, are they the big black "void" bushes in the middle?

If not then please ignore all the following, but if it is then:

1) It's not surprising you were seeing a lot of rear wheel steering, those bushes must have made the handling of the scooter a bit woolly, let

along a trike.

2) Your A frame location is going to be introducing all sorts of nasty stresses as suspension compresses, since the A frame pivot points aren't

in-line with the bushes. In fact if it wasn't a void bush the suspension would now be locked solid, since the bush is now effectively serving

double duty as a suspension spring. If the void bush runs out of travel before the main spring, then something is going to get broken, probably the

gearbox casting.

3) The entire assembly will be trying to pivot around the A frame fixing on the gearbox under cornering loads, which will still be causing the void

bushes to deflect and induce rear wheel steering.

If this is the case I'd get rid of the A frame ASAP and get solid bushes/bearings made to replace the void bushes.

smart51 - 4/7/13 at 06:17 AM

Hi Mike,

The enormous bush you can see is there to allow the engine to move up and down a bit under shock loads. The trailing arm to engine bushes a really

quite small and are hidden from view in the photo. The A frame pivots and the trailing arm pivots are not quite in line but the difference is very

small. All the movement can be taken up by the mechanism that allows the engine to move.

I've just fitted a stiffer anti roll bar at the front. When I next go out, I'll see if that makes any difference.

Slimy38 - 4/7/13 at 07:30 AM

quote:

Originally posted by MikeR

read this and remembered something a friend told of about riding a bike on the motorway. you get a flat spot as the bike is vertical. when you do your

first corner it can be scary as you go onto a narrow ridge of rubber so don't have masses of grip.. could the lean of the corner force you onto a

narrow strip of rubber.

That happens when a bike is predominantly used for long distances on straight roads. You're actually 'squaring off' a round profile

wheel, and while I'm not sure about the narrow ridge, there is a definite 'step' as you tip the bike over.

However, a trike will never get up to the angles necessary to induce this kind of effect. In fact, the usual approach for trikes using bike parts is

to replace the normally round profile bike tyre with a regular 'flat' car tyre.

smart51, I noticed you've said there is some wear off centre, I wonder whether it might be worth investigating that a little? Draw some chalk

lines across the tyre, and see how much is getting removed. If the wear on the chalk marks are further up than the lean of the trike suggests, then

there is definitely something odd going on with the back end.

smart51 - 4/7/13 at 07:38 AM

Chalk marks are a great idea. I'll try to find some chalk. Thanks.

Mr Whippy - 4/7/13 at 12:17 PM

Reading through everything it seems really the problem is having tyres for a leaning bike on a vehicle that doesn't lean to turn. When riding a

motor bike at speed you don't actually turn the handlebar to turn, you lean the bike over and the bar turns with the bike. Try it, without

leaning the bike the handle bar will not turn.

Now you have a trike that both can turn like a car and a bike so when you turn the wheels and the body rolls the two just feed back on each other,

it's no wonder its a handful. Put narrow car tyres on and it will be fine.

[Edited on 4/7/13 by Mr Whippy]

Slimy38 - 4/7/13 at 01:00 PM

quote:

Originally posted by Mr Whippy

Reading through everything it seems really the problem is having tyres for a leaning bike on a vehicle that doesn't lean to turn. When riding a

motor bike at speed you don't actually turn the handlebar to turn, you lean the bike over and the bar turns with the bike. Try it, without

leaning the bike the handle bar will not turn.

[Edited on 4/7/13 by Mr Whippy]

I'm afraid it's the other way round, you cannot lean a bike over without turning the handlebars (well, at least most of the time). Have a

read of this;

http://www.superbikeschool.com/machinery/no-bs-machine.php

Sorry OP, I'm slightly off topic here, but just wanted to clear this one up.

MikeRJ - 4/7/13 at 03:47 PM

quote:

Originally posted by smart51

Hi Mike,

The enormous bush you can see is there to allow the engine to move up and down a bit under shock loads. The trailing arm to engine bushes a really

quite small and are hidden from view in the photo. The A frame pivots and the trailing arm pivots are not quite in line but the difference is very

small. All the movement can be taken up by the mechanism that allows the engine to move.

I've just fitted a stiffer anti roll bar at the front. When I next go out, I'll see if that makes any difference.

I'm glad to hear this, I had visions of something expensive breaking!

Just a thought; is it possible that whilst you might have constrained the axle enough to prevent it "steering" in the obvious direction,

could the engine/gearbox be twisting axially (i.e. twisting in the axis of a line running from the front to the back of the car) under load?

Mr Whippy - 4/7/13 at 04:33 PM

quote:

Originally posted by Slimy38

quote:

Originally posted by Mr Whippy

Reading through everything it seems really the problem is having tyres for a leaning bike on a vehicle that doesn't lean to turn. When riding a

motor bike at speed you don't actually turn the handlebar to turn, you lean the bike over and the bar turns with the bike. Try it, without

leaning the bike the handle bar will not turn.

[Edited on 4/7/13 by Mr Whippy]

I'm afraid it's the other way round, you cannot lean a bike over without turning the handlebars (well, at least most of the time). Have a

read of this;

http://www.superbikeschool.com/machinery/no-bs-machine.php

Sorry OP, I'm slightly off topic here, but just wanted to clear this one up.

If you ride a motor bike like me, just try and turn the handle bars at about 30mph without tilting the bike, it won't turn

The article you refer to is about folk leaning their upper body over to tilt the bike which as is stated is not right, you actually use your hips and

move your lower body, the bike then follows, it's also how you can ride without any hands

Slimy38 - 4/7/13 at 04:55 PM

quote:

Originally posted by Mr Whippy

If you ride a motor bike like me, just try and turn the handle bars at about 30mph without tilting the bike, it won't turn

The article you refer to is about folk leaning their upper body over to tilt the bike which as is stated is not right, you actually use your hips and

move your lower body, the bike then follows, it's also how you can ride without any hands

As a fellow bike rider, I think we may have to agree to disagree on that one!  Although I do agree you can't steer without leaning the bike,

otherwise it would just flop over! I just don't agree that you can steer with no bar input. Maybe just about to change lanes, you won't be

getting round any roundabouts!

Although I do agree you can't steer without leaning the bike,

otherwise it would just flop over! I just don't agree that you can steer with no bar input. Maybe just about to change lanes, you won't be

getting round any roundabouts!

[Edited on 4/7/13 by Slimy38]

Fred W B - 4/7/13 at 05:05 PM

Can you not find a Gopro camera somewhere and strap it on the frame looking back along the swingarm.? Then go for a ride and record what is actually

happening to view later.

WRT discussion above I agree that pushing forward on the inner bar is the way to make a bike turn. I was amazed when I first read about that and tried

it. It steers the front a little out from under you, makes the bike lean into the corner and then you go round the corner like you mean it!  Try it

sitting bolt upright on the bike and you will feel it too.

Try it

sitting bolt upright on the bike and you will feel it too.

Cheers

Fred W B

[Edited on 4/7/13 by Fred W B]

[Edited on 4/7/13 by Fred W B]

on_eighty_runner - 4/7/13 at 05:26 PM

Hi there great project!

The back end on a scooter is not that rigid in torsion as A scooter doesn't need that much.

I had a gilera 180 with what seems to be the same rear swing arm mount and there was give right to left at the rear wheel.

As the 2 strokes only had one rear shock unit as the bushes wore in the mount you would see the wheel start to lean over under weighy giving odd tyre

wear

I suggest you try to control the wheel a little tighter as it is probably moving around more than you realise in its new home

As it looks like Piaggio 4 stroke I assume it has 2 rear shocks.

These are quite close to the wheel axle

A rose joint linkage from the shock mounts to the right and left edges of the chassis (with these ends inline with the swingarm pivot)should very good

control right to left

If you could take another pair from under the swingarm casing to the same right and left chassis points this will control the wheel vertically

You will then have in effect 2 large A arms holding the wheel in 2 axes but still being able the pivot around the third ( the swing arm)

Bushes may be good enough and will give better vibration absorption

The big rubber donut is quite soft and isolates vibration from the big single engines at idle. It is not fitted to 50ccs

Best of luck

smart51 - 5/7/13 at 08:20 PM

The stiffer anti roll bar has made a big difference to the handling. There is noticeable reduction in body roll but no change in ride comfort, which

is nice. The high speed stability is improved too but it still isn't quite right. I'll have a think about it a bit more. I'ts

definitely getting there though.

MikeRJ - 5/7/13 at 08:52 PM

quote:

Originally posted by Mr Whippy

The article you refer to is about folk leaning their upper body over to tilt the bike which as is stated is not right, you actually use your hips and

move your lower body, the bike then follows, it's also how you can ride without any hands

It doen't matter which bits of your body you try to use to lean a bike, if you don't countersteer using the bars then the best you'll

ever get at normal road speeds is a turning circle the size of a supertanker. You HAVE to use the bars to steer, as the machine linked to above

proves.

On a pushbike your body weight has a lot more effect, obviously, but even then if you are doing 20-30mph you won;t steer much by just leaning.

[Edited on 5/7/13 by MikeRJ]

Dave Ashurst - 5/7/13 at 09:45 PM

Not sure if you've solved it now but if not then could you record the rear end motion with a strategically-mounted video camera under the car?

Would that help spot the source of movement? Better to cure it than mask it. Perhaps you could record movement from driving combinations with and

without front anti-roll bar and a-frame.

I've got an old bullet cam, clamp mount and recorder somewhere. You can borrow them if you I can find them (we moved house!). Give me a call.

best

D

Dick Axtell - 6/7/13 at 12:52 PM

Hi. Been following your new project with interest. Then I recalled encountering a Dr. Edmund Jephcott, who tried (unsuccessfully) to promote his

tilting trike, with patented tilt control mechanism.

Check out here :- http://www.maxmatic.com/ttw_moto.htm

Getting your trike to lean into the turn might alleviate your probs?

smart51 - 26/7/13 at 04:44 PM

OK now we're getting somewhere. I've stiffened up the A frame by putting a cross bar on it, turning it from a V frame to a proper A frame.

I also strengthened the mounting brackets on the chassis. It has made a big improvement and the handling is now quite good. The springy effect when

suddenly turning in is still there a little bit but it is not objectionable unless you're really chucking it in at around 60 or so. I'll

still see of I can make it better still but I'm almost there.

Now the bad news. Everything is now very stiff and all of the single cylinder engine vibrations find their way to the chassis and through to the

driver's seat. I'll probably have to make a whole n swing arm that allows some vertical movement of the engine but absolutely no lateral

movement.

smart51 - 16/12/14 at 12:17 PM

Update after a bit(!) of a gap. I'd tried lots of things to stiffen up the rear trailing arm to solve the handling problem. All of them made is

slightly better, but not enough. I finally got round to fitting a car tyre to replace the rear bike tyre. That made things worse. I suspect because

it increased rear end grip, exscserbating the cause of the problem.

After some procrastination, I took the advice of a friend and stiffened up the chassis. I had assumed that as the trike has 3 wheels, there would be

no twisting moment on the chassis. I was wrong. Thinking about it, cornering forces act on the CofG and on the 3 wheels, making 4 "points of

contact" which is enough to twist the chassis.

Brace Frame

I made an axilliary frame running the length of the body with 3 X braces. This was welded to the exisiting floor structure which looks a bit like a

ladder chassis from underneath. It has made a noticable difference. The car has less sway at speed, though is still not 100%. I haven't tried

any fast corners yet because the roads are wet, but on the next dry day we get, guess what I'm going to do  Meanwhile, I need to think of more

ways of stiffening my trike's frame.

Meanwhile, I need to think of more

ways of stiffening my trike's frame.

So I've learned a lesson. Trikes need a chassis that is stiff in torsion.

smart51 - 23/12/14 at 03:45 PM

Now the chassis has been stiffened up, I've been playing with toe settings. A little toe out is better than parallel, which is better than toe

in. Still more to do, but we're getting there now.

smart51 - 30/12/14 at 11:30 AM

Another day, another mod and this one has made a big difference. Stiffening up the rear of the chassis has improved the high speed stability so that

it's almost hands free at 70. There's still a little more to do but I'm almost there.

Try it

sitting bolt upright on the bike and you will feel it too.

Try it

sitting bolt upright on the bike and you will feel it too.