saigonij

|

| posted on 10/11/07 at 08:11 AM |

|

|

bottom seat belt mounts

been wondering if the small triangle piece welded in to the luego chassis is enough for SVA? i have seen a few pictures ( cant find them now ) where

people have used a small 3mm thick trianglular piece of metal with a nut welded on to it...

will sva be fine with what on the current chassis? ( do you need to see pics? )

|

|

|

|

|

snapper

|

| posted on 10/11/07 at 09:25 AM |

|

|

SVA needs to be happy with the strength of the mounting (fit for purpose) I have large (100mm square) load spreading plates on a stainless

monocoque.

Whilst a triangular plate welded on 2 sides to the chassis may be OK, i would also weld a support tube if you can

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

907

|

| posted on 10/11/07 at 01:08 PM |

|

|

Hi Saigonij,

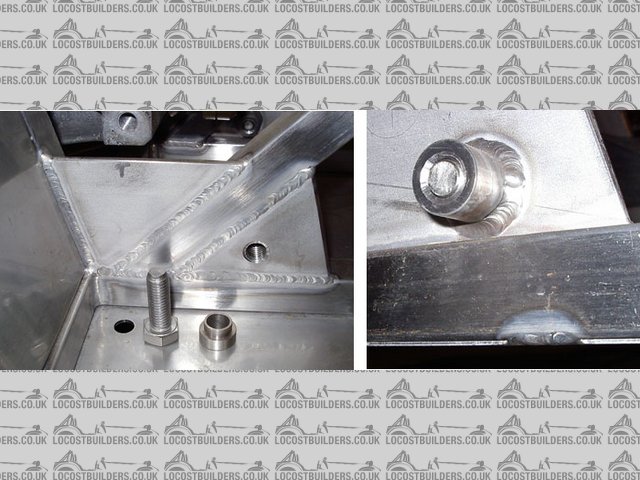

The pics below show what I have done to spread the load into the chassis.

I think this is what the SVA man will want to see, he says hopefully.

Although I am building in stainless I would think the same sort of thing would be OK in mild steel.

I have made 25dia bosses, instead of nuts, and welded them to 4mm plate, then tapped through,

which has then been bevelled to form the weld prep, then welded in place.

(I understand that welded nuts have passed OK.)

The stepped washers allow the belt end plates to turn so that whatever angle they are pulled from it's a straight pull.

As I interpret the SVA manual this is how it's supposed to be.

My only personal issue is the use of stainless steel, but hopefully I can bluff my way through that one.

hth

Paul G

Please ignore the hole to the bottom left.

That's a water drain hole in the floor.

[Edited on 10/11/07 by 907]

Rescued attachment Seat-Belt-Mount-s.jpg

|

|

|

snapper

|

| posted on 10/11/07 at 02:38 PM |

|

|

Very neat welding 907.

I am on a welding course from January (now my build is nearly complete) hope my welding looks that good

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

907

|

| posted on 10/11/07 at 02:49 PM |

|

|

quote:

Originally posted by snapper

Very neat welding 907.

I am on a welding course from January (now my build is nearly complete) hope my welding looks that good

Thanks neighbour. (well fairly close)

What course are you doing? Mig? Tig?

Paul G

|

|

|

Echidna

|

| posted on 10/11/07 at 03:44 PM |

|

|

Hey 907, your welds look awesome!

What type of welding machine do you use and which brand?

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

907

|

| posted on 10/11/07 at 04:09 PM |

|

|

quote:

Originally posted by Echidna

Hey 907, your welds look awesome!

What type of welding machine do you use and which brand?

Hi Echidna

Those I did a while ago with my SureWeld 165 DC Tig.

I've upgraded to an AC/DC Tig so that I could make my bodywork, nose etc.

I bought a second hand Miller Dynasty DX Tig and I'm still trying to get my head round all the settings.

I think there's even one for making toast.

Cheers

Paul G

|

|

|