the moa 2

|

| posted on 4/1/05 at 09:16 PM |

|

|

gear lever position ?

hi,

just about to put dash board in and we have realised that the gear lever is going to hit the dash board when you put it in to 1 st , 3rd and 5th.we

bent it a bit but still no difference. has anyone had this problem before.

(we ve got a pinto with type 9 box)

|

|

|

|

|

rusty nuts

|

| posted on 4/1/05 at 09:21 PM |

|

|

Probably worth doing a search , i'm sure this has been covered as I had the same problem and found the solution on this forum. hope this helps

Rusty

|

|

|

tom_loughlin

|

| posted on 4/1/05 at 09:33 PM |

|

|

thats wierd, i trial fitted my gearstick this afternoon and had exactly the same thought.

at exeter i saw a few solutions to this, but all of them seemed a bit bodged to me.

will be interested to see replies on this subject

Tom

|

|

|

CairB

|

| posted on 4/1/05 at 09:41 PM |

|

|

One solution is to remove the upper portion of the gear lever.

It is connected to the lower section by a rubber junction.

I did this and found that a gear stick knob from a local factors fitted the stub when the sleeve was removed.

It makes it a tad of a quickshift but costs only a bit of time.

Cheers,

Colin

|

|

|

the moa 2

|

| posted on 4/1/05 at 11:01 PM |

|

|

Missing the dash is only half the problem as ive noticed i can reach the "shifter" but its a bit of a stretch and would ideally need it

closer to me.

I think it looks like we gonna have to cut and reweld it with a nice big angle on it.

|

|

|

Mark Allanson

|

| posted on 4/1/05 at 11:12 PM |

|

|

I partially cut mine just above the damper block and rewelded - which burnt the rubber and made the lever VERY sloppy. I then had to weld a washer on

the bottom of the damper to make the lever rigid!

The gear lever is now completely horizontal when in second and forth, but is very comfortable to use, and at my ideal reach.

Rescued attachment Gearlever Clearance.JPG

If you can keep you head, whilst all others around you are losing theirs, you are not fully aware of the situation

|

|

|

Avoneer

|

| posted on 4/1/05 at 11:50 PM |

|

|

Westie remote?

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

Rob Lane

|

| posted on 4/1/05 at 11:54 PM |

|

|

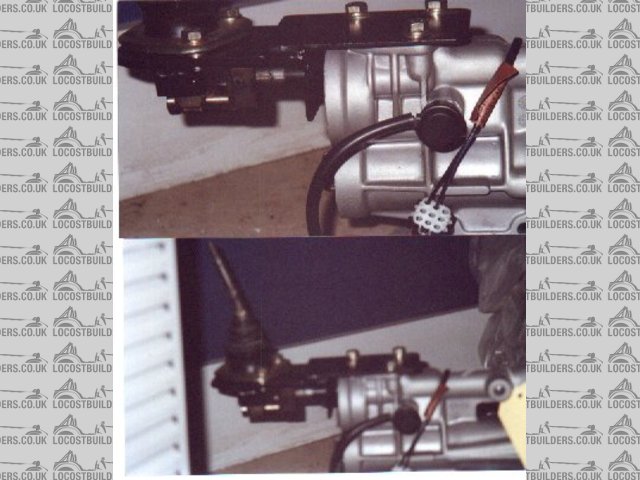

You need a remote like this.

Ideally the gearknob when in neutral should be approx. level with steering wheel, so hand falls from wheel to gearchange naturally.

[Edited on 4/1/05 by Rob Lane]

Rescued attachment Gearstik.jpg

|

|

|

timf

|

| posted on 5/1/05 at 08:24 AM |

|

|

have a look on david jenkins website

|

|

|

rusty nuts

|

| posted on 5/1/05 at 06:33 PM |

|

|

Yes the David Jenkins website was very helpful shows how to make a quickshift remote, mine cost less than £1.00 to make and that was for the plastic

part at the lower end of gear lever. Do a search for I can't reach my shifter, also covers this topic. Worth spending a bit of time to get it

right. Also somebody was selling some remotes on this forum some time ago ,may have some left?? hope this is of some help.Rusty

|

|

|

albertz

|

| posted on 5/1/05 at 08:29 PM |

|

|

Heres the link, incase you havent found it yet;

http://www.dwjenkins.plus.com/gear_extend.htm

I used this method and it works a treat as well as being very cheap to do. It solved the problem for me anyway.

|

|

|

David Jenkins

|

| posted on 5/1/05 at 09:41 PM |

|

|

Fame at last!

The only comment I can make is - don't make the gearlever too short, as the quick-shift modification reduces the leverage. I cut off the rubber

damper thingy and found that the remaining stalk was just a little too short. It was fine after adding a 2 or 3 inch extension (I made a longer

adaptor sleeve for the gearknob).

have fun!

David

|

|

|

the moa 2

|

| posted on 6/1/05 at 12:13 AM |

|

|

Wow lots of info there didn't realize this would have been a major issue and that kit car designers haven't yet made chassis that suits

the gearbox a bit better.

The guides look very in depth and a nice walk through guide but not being a engineer with engineering skills im not sure im up for the challenge,

althought im am certainly gonna take a good look at it.

What are the major issues if there are any on just cutting the lever just above the shaft and below the weird blobby bit which is about a quarter up

the stick, and then welding it back on just at an angle. ?

|

|

|

David Jenkins

|

| posted on 6/1/05 at 08:15 AM |

|

|

Only that your gearshift "H" pattern is going to be nearly vertical, instead of horizontal. Apart from that, loads of people have done it

and been happy with the result.

If you're not up to making your own shift extension, have a look at the Westfield one - vaguely the same as mine, but more expensive!

cheers,

David

|

|

|

DaveFJ

|

| posted on 6/1/05 at 09:42 AM |

|

|

Looks like your gonna have to go into production Dave, or perhaps Darren @ GTS could start selling them ? (only with Dave's permission of

course)

Dave

"In Support of Help the Heroes" - Always

|

|

|

David Jenkins

|

| posted on 6/1/05 at 09:45 AM |

|

|

I had wondered about that...

... means opening up the transmission tunnel and measuring the bits properly (they were "fitted" originally, i.e. adjustments made as work

progressed to make things work)

DJ

[Edited on 6/1/05 by David Jenkins]

|

|

|

DarrenW

|

| posted on 6/1/05 at 10:33 AM |

|

|

Mac#1Motorsport do an extension for the type 9 box. I think they are about £65 from memory. My chassis is redesigned to fit the gearbox further back

so the extension is not needed (probably helps weight distribution as well as engine is further back).

|

|

|

rusty nuts

|

| posted on 6/1/05 at 06:40 PM |

|

|

check out the for sale section for details of who was thinking of having some made. Rusty

|

|

|

zetec

|

| posted on 6/1/05 at 07:14 PM |

|

|

You could always use a MT75 "box. The gear lever is really easy to relocate on that...blah blah blah.

" I only registered to look at the pictures, now I'm stuck with this username for the rest of my life!"

|

|

|

Peteff

|

| posted on 6/1/05 at 08:02 PM |

|

|

Mount it all 4" further back

Mine's in the right place and it's a Pinto with a type 9 box.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Ian Pearson

|

| posted on 6/1/05 at 10:37 PM |

|

|

quote:

Mine's in the right place and it's a Pinto with a type 9 box.

Ditto.

|

|

|

the moa 2

|

| posted on 8/1/05 at 06:41 PM |

|

|

Just had a chance to look at a westfield remote and i can now understand how it works .

£80 odd quid its gonna cost and i think unless i find a second hand one or if someone here is knocking them out i shall get one of them!

One thing i noticed different from westy's one and then one in the guides from d.jenkins and his pal is the way you dont have to drill or alter

my type 9 gearbox in any way as oposed to drilling in the plate just above the prop.

Well if anyone does have one for sale please let me know . Original or not !

|

|

|

andyace

|

| posted on 8/1/05 at 07:33 PM |

|

|

Pinto with Type 9

I hve a 2.0 pinto with type 9 box, how far do I have to try and set it back to get the gearstick in the correct place?

Thanks

|

|

|

Peteff

|

| posted on 8/1/05 at 07:55 PM |

|

|

About here.

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=scuttle_off.jpg

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

andyace

|

| posted on 8/1/05 at 10:47 PM |

|

|

Cheers does the position of the gearstick measure easy from any point on the chassis so I can ensure I get it in the correct place?

Also did you make any chassis mods to get the gearbox further back?

Thanks, Andy

|

|

|