TimC

|

| posted on 8/4/12 at 07:13 PM |

|

|

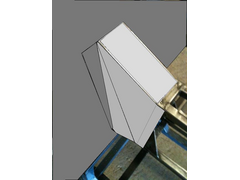

How on earth do I panel this?

I'm almost bald from scratching my head on this one. The Gemini has a number of panels that require a bit of thought but this one has me

stumped. How do I cut and bend aluminium so that the sides at the rear of the tunnel are enclosed?

How?

Confused.

|

|

|

|

|

madteg

|

| posted on 8/4/12 at 07:29 PM |

|

|

Make a template out of cardboard fold into position and trim to size. Now make out of ali

|

|

|

Talon Motorsport

|

| posted on 8/4/12 at 07:32 PM |

|

|

I would start with thick single layer card board untill you are happy with the shape and over laps, make your mistakes in some thing cheap and easily

cut before you start cutting either ali or steel.

|

|

|

jacko

|

| posted on 8/4/12 at 07:32 PM |

|

|

easy

Back panel on small angles down the rear where the tunnel panel buts up to rivet to .

mark the panel on the tunnel top bar then bend it using two bits of steel angel

|

|

|

TimC

|

| posted on 8/4/12 at 07:33 PM |

|

|

quote:

Originally posted by madteg

Make a template out of cardboard fold into position and trim to size. Now make out of ali

Yes, been trying to do that but I can't figure out how a panel can meet all of the tubes.

[Edited on 8/4/12 by TimC]

|

|

|

hicost blade

|

| posted on 8/4/12 at 07:35 PM |

|

|

Wanna buy my folder

|

|

|

gottabedone

|

| posted on 8/4/12 at 07:36 PM |

|

|

If you panel the side of the tunnel with a right angle that runs vertically from the inside of the tunnel bottom (where the seatback is) to the

outside of the tunnel top, you can rivet to the piece where the seat back is.

not sure if that makes any sense at all

|

|

|

Slimy38

|

| posted on 8/4/12 at 07:51 PM |

|

|

Are those top bars in the right place? I'd have expected them to meet the taped bar a little further away from the center, and therefore make

them parallel to the bottom bars (and consequentially easier to panel!).

Although thinking about it, I think gottabedone is referring to the same line to put a panel right angle in. So imagine those parallel bars staying in

line with the bottom, put the right angles where I think the bars should be.

Either way (move the bars or right angle the panel) will lose you a couple of inches of shoulder room unfortunately.

|

|

|

TimC

|

| posted on 8/4/12 at 07:55 PM |

|

|

quote:

Originally posted by Slimy38

Are those top bars in the right place? I'd have expected them to meet the taped bar a little further away from the center, and therefore make

them parallel to the bottom bars (and consequentially easier to panel!).

Although thinking about it, I think gottabedone is referring to the same line to put a panel right angle in. So imagine those parallel bars staying in

line with the bottom, put the right angles where I think the bars should be.

Either way (move the bars or right angle the panel) will lose you a couple of inches of shoulder room unfortunately.

Yeah, the bars are as per all other Geminis I've seen. The footwells also require the type of bends that you just don't get on Locosts,

MKs, Strikers and MNRs...

|

|

|

Chippy

|

| posted on 8/4/12 at 10:33 PM |

|

|

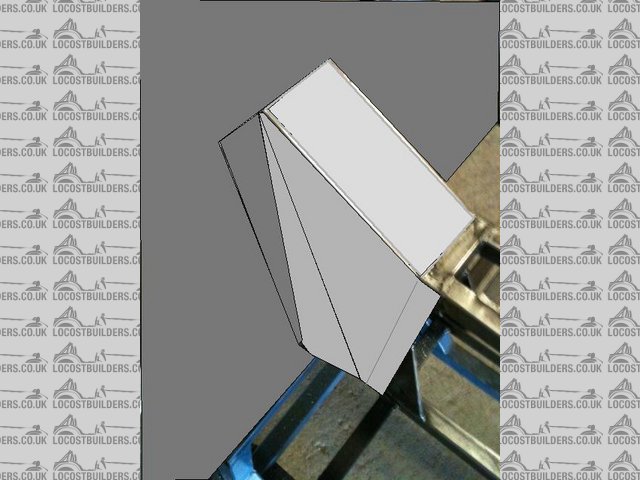

This is how I would tackle it, basicaly in three parts. First the red section then green and finaly the yellow bit at 90 deg's to the green,

easily formed in some stiff card then transfer to your piece of ally. Hope that makes sense, :-) HTH Ray

[img]

[/img]

To make a car go faster, just add lightness. Colin Chapman - OR - fit a bigger engine. Chippy

|

|

|

blakep82

|

| posted on 8/4/12 at 11:18 PM |

|

|

does it have to be metal? could it be GRP? or rather, some sort of composite?

wrap it in cling film to stop the resins sticking, then get some cheap fleece (tesco, £6 for a fleece back in october, not sure if they're still

around or at that price) stretch it over the tubes, cover in fibreglass resin, leave to set, job done (except for removing trimming, get the cling

film off, the re-fixing it with sikaflex or something)

thats how i'd do it

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

TimC

|

| posted on 9/4/12 at 09:37 AM |

|

|

OK, going to give this a go then - a little concerned that it won't clear diff/prop. Thanks for your help!

Panelling by Paint

|

|

|

DIY Si

|

| posted on 9/4/12 at 09:53 AM |

|

|

If you're worried about clearance, then have the panel follow the line of the bottom tube. The fold can be in mid-air with no problems at all.

Like this. The green line is the only fold needed this way:

Although it needn't stop on the top tube as I've shown it, and could easily extend across the tunnel top. Or further forwards for the

whole tunnel side if you're feeling brave!

[Edited on 9/4/12 by DIY Si]

“Let your plans be dark and as impenetratable as night, and when you move, fall like a thunderbolt.”

Sun Tzu, The Art of War

My new blog: http://spritecave.blogspot.co.uk/

|

|

|

rusty nuts

|

| posted on 9/4/12 at 11:45 AM |

|

|

Suspect you will have plenty of clearance for the prop, if you haven't then the chassis will be in the way ? When making cardboard templates use

a straight edge to make any bends rather and make them bigger than you think they should be , it's always easier to reduce the size rather than

make them bigger. Also allow for any overlap on joins , it may be neater to over lap rather than a butt joint ? Just keep working at it until you are

happy

|

|

|