Lowe dash 19mm radius ideas

the_big_1 - 27/3/21 at 09:32 AM

Hi guys,

Search function still not working 😪

How have you achieved, what have you used etc, so I can get some ideas, of how you managed to get the minimum lower dash radius or 19mm?

Cheers all

jps - 27/3/21 at 10:14 AM

What are you making your dash from? I’m using 2mm all sheet and, although I’ve only tried on an off cut, will just roll the bottom around a piece of

round tubing.

Btw: if you put ‘ site:locostbuilders.co.uk dashboard radius ‘ into Google you’ll get results only from this site.

[Edited on 27/3/21 by jps]

the_big_1 - 27/3/21 at 10:17 AM

Hi ya,

Yeah I am using 2mm ally too. My issue is the bottom isn't a straight line, sort of up 45 degrees, round turn, across, round turn, 45 degrees and

down to tunnel.

Slater - 27/3/21 at 02:12 PM

Mine is the same shape with angled sections at both ends and down to the tunnel, I made mine with 6mm MDF sheet and then glued 40mm wooden batons to

the lower edges. I used spoke shave to get the 19mm radius, all sanded down nice and smooth, primed/sealed and painted a few layers of outdoor gloss

and a final coat of dry film lube from an aerosol to give it satin black look I was after.

snapper - 28/3/21 at 07:20 AM

Plastic 40mm waste pipe, it has a 20mm radius, you can cut it, use PCV glue to stick it, heat to bend it, sikaflex to secure it although I just cut a

slot in it and pushed it on then used yoga mat or camping mat to cover it.

robertst - 28/3/21 at 10:16 AM

My dash is marine plywood covered with leather. No padding. What I did to comply with IVA was cut and form edge trims from a sheet of ali with a

couple of bolts bonded to them and covered in the same leather so that they fix on the underside with wingnuts.

If I had known the 19mm radius thing when I made the dash, i would have integrated them into the dash before wrapping the leather, but it doesn't

look terrible as is.

[Edited on 28/3/21 by robertst]

40inches - 28/3/21 at 10:52 AM

You can use ally gutter profile to make the edge,

Description

Description

Description

like this

Slit the flat edge multiple times at the curve point and bend to shape

If you cover with self adhesive sponge you only need a 5mm radius:

7.The instrument panel lower edge within the specified zone must have a radius of curvature not less than 19mm or 5mm and be covered with a

non-rigid material, except where an adaptation for a disabled person makes it impossible to comply (see Notes 6&7).

[Edited on 28-3-21 by 40inches]

pewe - 29/3/21 at 10:07 AM

I used a section of blue mains water pipe slit along its length, contact adhesived on then covered in some of the black convoluted cable trunking you

use on wiring harnesses.

Worked for me and deffo a lo-cost solution.

PS still have a load of the blue stuff if you want a short length -PM me.

PPS you could always cover the blue tubing in leather-cloth if you wanted a "professional" finish.

[Edited on 29/3/21 by pewe]

the_big_1 - 30/3/21 at 10:11 AM

Hi guys,

How would they determine that the 5mm is ok,

The 19mm is obvious but how can I do the edge to be 5mm. If I cam covering the whole dash with this,

https://www.carbuilder.com/uk/carbon-effect-vinyl-cloth-per-metre

Could it just be the 2mm Aluminium folded over then covered in the above?

40inches - 30/3/21 at 10:34 AM

quote:

Originally posted by the_big_1

Hi guys,

How would they determine that the 5mm is ok,

The 19mm is obvious but how can I do the edge to be 5mm. If I cam covering the whole dash with this,

https://www.carbuilder.com/uk/carbon-effect-vinyl-cloth-per-metre

Could it just be the 2mm Aluminium folded over then covered in the above?

5mm is the radius of the bottom of the dash, so ally folded over something 10mm diameter and then covered with foam,

or use the ally profile that I used.

If you are using vinyl cloth straight onto the dash it would need to be 19mm radius. I used 3mm foam adhesive under the vinyl around the curve. The

examiner tests the bottom of the dash with his fingers to check it is soft

the_big_1 - 30/3/21 at 10:45 AM

So I guess I could use 10mm tube with the 3mm foam just on the lower edge, then cover it all in the vinyl?

Tube could be flexi pipe etc so I can do the curves etc.

40inches - 30/3/21 at 10:48 AM

quote:

Originally posted by the_big_1

So I guess I could use 10mm tube with the 3mm foam just on the lower edge, then cover it all in the vinyl?

Tube could be flexi pipe etc so I can do the curves etc.

Whatever you think looks best will work

the_big_1 - 30/3/21 at 10:50 AM

What gutter edging did you use?

40inches - 30/3/21 at 12:46 PM

quote:

Originally posted by the_big_1

What gutter edging did you use?

This would do https://www.clickmetal.co.uk/click-by-category/mouldings/aluminium-gutter-moulding-no-02

the_big_1 - 30/3/21 at 12:53 PM

Hi ya,

Looks a good idea. How did you attach it? Did you fill the gap or do something to blend in the joint and the foam start point etc?

40inches - 30/3/21 at 02:06 PM

quote:

Originally posted by the_big_1

Hi ya,

Looks a good idea. How did you attach it? Did you fill the gap or do something to blend in the joint and the foam start point etc?

Attached with C/SK pop rivets on the back of the panel and used the step to butt up to with the foam, you could fit washers between

to give the depth of the foam, or in your case the difference would only be 1mm so the vinyl would squash the edge flush.

the_big_1 - 30/3/21 at 02:17 PM

Hi ya,

Perfect.

I guess I would have a 2mm step to the gutter as my ally is 2mm thick. Add 4mm means the foam would be 2mm higher.

might try a washer etc, see if I could get it so the foam is level with the ally so when the vinyl goes over, there isn't a line or anything.

adithorp - 30/3/21 at 03:15 PM

quote:

Originally posted by 40inches

...The examiner tests the bottom of the dash with his fingers to check it is soft

If when he does that, he can feel the ally through it, it'll fail. ...well probably fail and that's an expensive "probably" plus

quite a bit of work to correct.

PS. Remember it's 19mm diameter not radius. Sorry if that sounds daft but people have made that mistake before now.

the_big_1 - 30/3/21 at 03:30 PM

Hi ya,

manual says "The instrument panel lower edge within the “specified zone” must have a

radius of curvature not less than 19mm or 5mm and be covered with a

non-rigid material," its radius, not diameter lol and radius is 2 x diameter so you would need say 38mm pipe to get a 19mm radius.

That's the issue, how much does he have to press to feel it to fail it? thats not mentioned

Bluemoon - 31/3/21 at 12:25 PM

Just formed mine 1.5mm thick ali sheet around a tube of suitable radius as a former. Stiffens up the dash nicely and is IVA compatible.

the_big_1 - 31/3/21 at 12:29 PM

Did you do the 5mm radius and foam or the 19mm without?

JAG - 31/3/21 at 02:51 PM

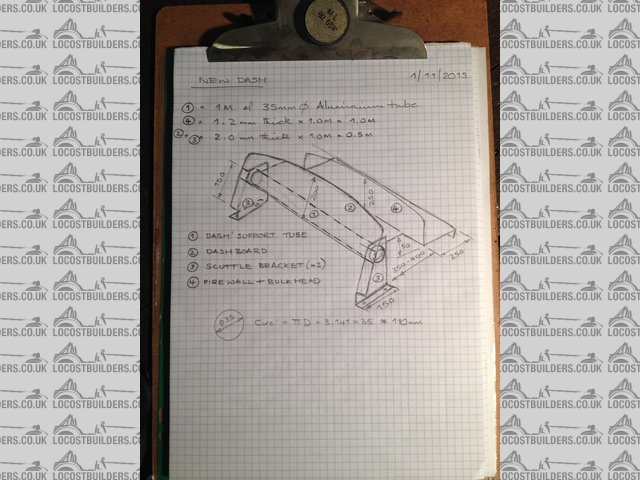

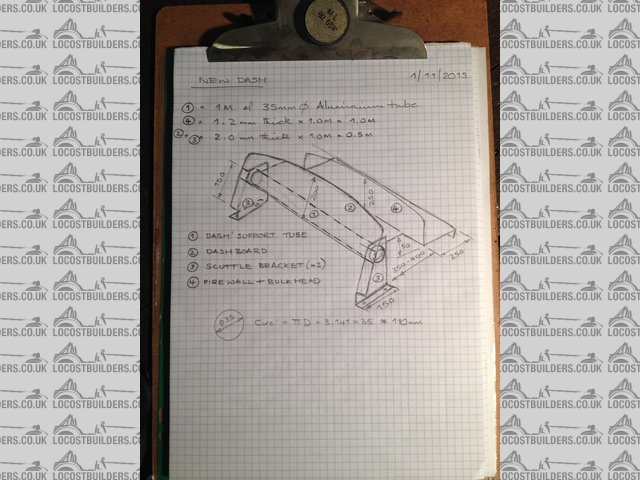

For my first attempt at the Dash' (lasted 10 years) I did this;

quote:

Just formed mine 1.5mm thick ali sheet around a tube of suitable radius as a former

My updated Dash' (which I am still working on) will use Aluminium tube as a structural cross-member with a 2mm thick Aluminium sheet forming the

Dashboard itself.

Like this...

November 2015 New Dash' cutting list

the_big_1 - 31/3/21 at 03:00 PM

Good plan.

If my lower dash was a straight line, some direction I would go for.

I have couple options,

Try form multiple edges around a 38mm pipe etc to get the 19mm form. 2mm aluminum might be tough to form. Vinyl straight on to the aluminum.

Try form multiple edges around a 10mm pipe etc to get the 5mm form. 2mm aluminum might be tough to form. Apply 4mm foam, then Vinyl.

Add J gutter trim with a 19mm Radius to the aluminum and pop rivet on. Apply 4mm foam, then Vinyl.