rumplitter

|

| posted on 13/6/08 at 08:35 AM |

|

|

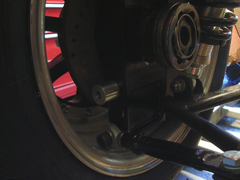

Hom much clearance do i need?

I've finally got round to fitting the alloy uprights that Jason supplied to me! I've been wrestling with one of the hubs that I had (another

story) Anyhow, got the hub and upright in position and the wheel wouldn't go on! The bottom arm was preventing the wheel from going on. I bit the

bullet and filed off (through my new powder-coating) and I've got about 1mm clearance all round. The wheel runs freely but do I need more

clearance? Do split rims flex?

How do I touch up the powder-coating?

PJH

Rescued attachment 12_06_08 078.jpg

http://www.locostbuilders.co.uk/upload/MiniMojoProject.JPG

|

|

|

|

|

Davey D

|

| posted on 13/6/08 at 08:43 AM |

|

|

if it was me, i wouldnt be happy with any less than 10mm or so clearance.... when your pushing it ( on track of course) at 100mph+ there are a lot of

forces at work that could cause flex in many places you wouldnt think it would.

i suppose the worse that could happen is that the inside of your wheel gets worn away

Edit: to patch up powdercoat i use some plasticote satin black anitrust paint that seems to match really well with black powdercoating

[Edited on 13/6/08 by Davey D]

|

|

|

Paul TigerB6

|

| posted on 13/6/08 at 10:01 AM |

|

|

HUUUUUUUGE pic. Can you please resize to say 600 x 450 pixels using something like Pixresizer??

linky

|

|

|

indykid

|

| posted on 13/6/08 at 12:57 PM |

|

|

ok then, i'll do it for you.

tom

Rescued attachment mini thing.jpg

|

|

|

clairetoo

|

| posted on 13/6/08 at 09:19 PM |

|

|

I'd have thought 1mm is a bit close , don't forget it's not just the wheel that may flex - any movement in the bearings or

suspension joints will be amplified at the rim ( if that makes sense ? )

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|