tegwin

|

| posted on 8/10/07 at 10:50 PM |

|

|

Fuel tank inlet annoyance

Having bought the worlds worst designed kit car over a year ago I have slowly gone through trying to rectify every design fault including lopping off

the front suspension and starting again...

But im having an issue with the fuel tank..

Its a thin stainless steel jobby....The sender sits in one end just fine...but the other end where the inlet is suposed to be is just a 2.5"

hole....

Somehow I need to perminatly attach a bit of pipe to the fuel tank so my inlet flexi can connect to it..

My initial thought was to get a stainless plate, cut a hole in the middle of it and weld on a suitably sized tube to take the inlet flexi....And then

use some kind of fuel resistant glue to bond the plate to the top of the tank..... Would this be acceptable? and are there any fuel proof mastic

sealants?

Idealy I would rivot the plate to the tank but as the tank is already embedded into the car with some fuel in it I cant risk drilling holes in the

tank and getting stainless swarf into the fuel system.....

Anyone have any cunning thoughts appart from torching the entire car and starting again?

|

|

|

|

|

Simon

|

| posted on 8/10/07 at 11:10 PM |

|

|

quote:

Originally posted by tegwin

My initial thought was to get a stainless plate, cut a hole in the middle of it and weld on a suitably sized tube to take the inlet flexi....And then

use some kind of fuel resistant glue to bond the plate to the top of the tank..... Would this be acceptable? and are there any fuel proof mastic

sealants?

My fuel sender is screwed to the tank with self tappers and they have been fine. Maybe use a proper fuel proof gasket. If you're concerned about

the self tappers coming undone, you could always crossdrill and lockwire them in place.

ATB

Simon

[Edited on 8/10/07 by Simon]

|

|

|

tegwin

|

| posted on 8/10/07 at 11:11 PM |

|

|

Im still going to have to drill holes in the tank to take the self tappers though which brings me back to the issue of swarf in the fuel

|

|

|

caber

|

| posted on 8/10/07 at 11:38 PM |

|

|

I would pull the tank out empty it and steam clean or water fill before attempting to drill, when cutting and drilling my stainless tank I got heating

and sparks not to mention a fair few broken HSS drills!

Caber

|

|

|

Dusty

|

| posted on 8/10/07 at 11:58 PM |

|

|

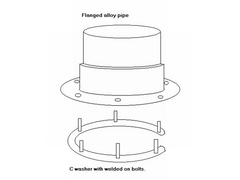

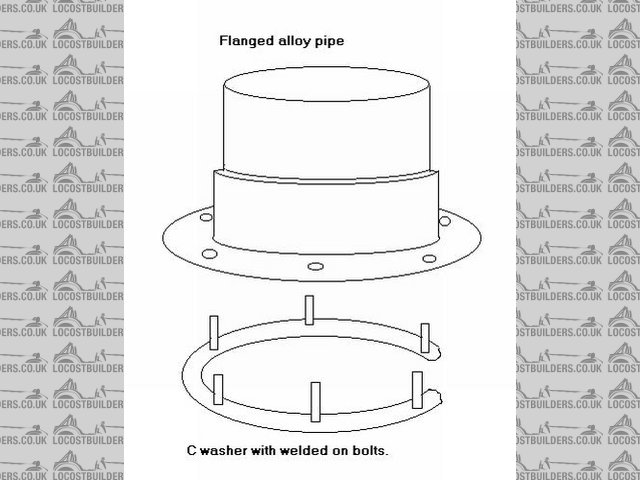

I found a flanged 2.5" tank connector and made up a C shaped plate to go inside the tank. welded six bolts to it and drilled holes in tank and

flange, like drawing. You will still have to take the tank out and clean it.

Rescued attachment tankconect.jpg

|

|

|

Avoneer

|

| posted on 9/10/07 at 06:41 AM |

|

|

Spoon covered in grease under the hole you are drilling will do the job.

Then use cheap £1 disposable filter just after the tank and throw it away and replace after a ew hundred miles.

Pat...

No trees were killed in the sending of this message.

However a large number of electrons were terribly inconvenienced.

|

|

|

robinj66

|

| posted on 9/10/07 at 08:17 AM |

|

|

I think the Robin Hood tank is designed to use the Sierra tank filler tube & rubber seal (still available from Ford). Fits quite well on my S7

.

Strangely the fuel sender won't fit - the studs are too short and in the wrong place. guess you get one good hole on each tank

|

|

|

NS Dev

|

| posted on 9/10/07 at 12:11 PM |

|

|

dont' know about the rh design, but have done the tank on a sierra and the rubber does just push in and is then held in place by the filler

spigot which shoves inside it, so should work ok.

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|

dave r

|

| posted on 9/10/07 at 07:38 PM |

|

|

buy a new ford rubber and they will seal

you can also make a spacer to make the tank a little thicker and use the old seal... mine lasted a long time like that

dave

|

|

|