markal

|

| posted on 17/3/07 at 08:03 PM |

|

|

How to cut drive shafts?

Could some one tell me, i want to mock some up first, the ones i bought are off a Granada 25 spline, my angle grinder will not touch them? and do you

cut them at an angle, so as to get more area to weld, regards Alan.

|

|

|

|

|

nitram38

|

| posted on 17/3/07 at 08:10 PM |

|

|

I have used a 14" chopsaw.

Only £57 delivered NTDWM

EBAY

|

|

|

jambojeef

|

| posted on 17/3/07 at 08:57 PM |

|

|

I presume you'll be sleeving the driveshafts so how would cutting them at an angle give you more area to weld to?

I may have not understood at all - in which case - sorry!

Geoff

|

|

|

nitram38

|

| posted on 17/3/07 at 09:02 PM |

|

|

If they are ground to a point, then welded, there will be more surface weld area.

Unfortunately, I do not think welded driveshafts or other things like welded track rods are allowed for sva.

Try douglas at west garage engineering service as he will make you the correct length ones.

|

|

|

rusty nuts

|

| posted on 17/3/07 at 09:33 PM |

|

|

Welded drive shafts are OK for SVA , not ideal but allowed. Welded track rods are not acceptable .

[Edited on 17/3/07 by rusty nuts]

|

|

|

nitram38

|

| posted on 17/3/07 at 09:38 PM |

|

|

In that case, weld them after grinding them to a point.

After welding put them in vee blocks and rotate them to see if they are straight.

Use a hammer to straighten them while in the vee blocks.

Sleeve over the weld and weld that.

Repeat with the vee blocks and hammer.

|

|

|

Wadders

|

| posted on 17/3/07 at 09:43 PM |

|

|

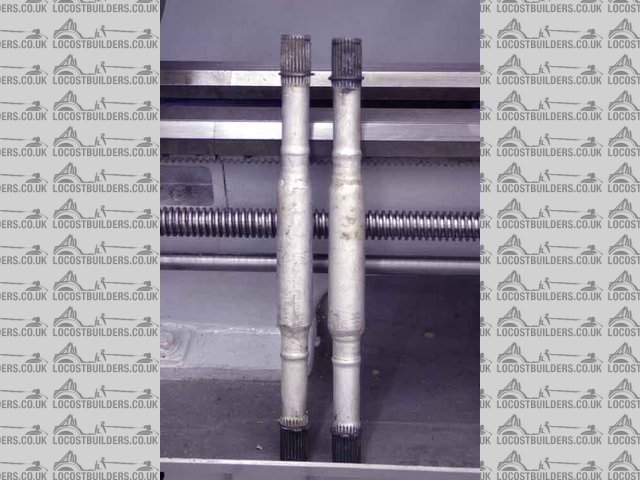

Better to go the custom made route, I reckon it would quite difficult, although not impossible to cut and shut them yourself

without introducing a degree of unbalance unless you had access to a lathe etc.

But unless something has changed recently cut and shut ones will pass the sva ok, as long as they look ok. Cutting should be no problem even with a

hacksaw, they're not made from anything special. To rejoin them weld a tight fitting sleeve over the joint. That how ST do theirs, dunno if they

turn them them true before sleeving though.

Here's a pic of the ST shafts, not particularly elegant or light, but i don't know of any ever failing.

Description

Al.

Originally posted by nitram38

If they are ground to a point, then welded, there will be more surface weld area.

Unfortunately, I do not think welded driveshafts or other things like welded track rods are allowed for sva.

Try douglas at west garage engineering service as he will make you the correct length ones.

|

|

|

BenB

|

| posted on 17/3/07 at 11:40 PM |

|

|

Yup- that's what I've got at the back.

Cut+shut+sprayed black....

|

|

|

trikerneil

|

| posted on 18/3/07 at 07:07 AM |

|

|

I scribed a line along mine then cut them with a 9" angle grinder. I turned up a couple of sleeves 0.001" smaller than the average shaft

diameter. These then were a shrink fit. Heat the sleeve, align the scribed line and push the lot together. Before it all cools down weld the assembly

together.

Worked for me, I've probably got about 80 BHP going through them.

There's more details on my website.

ACE Cafe - Just say No.

|

|

|